Ruthenium coated titanium electrode can effectively degrade organic pollutants in wastewater through electrochemical oxidation technology, significantly reducing heavy metal emissions. Their oxide coatings exhibit excellent corrosion resistance under acidic conditions and can efficiently capture heavy metal ions.

Electrochemical Fundamentals of Ruthenium Coated Titanium Electrode

Electrode reaction kinetics, as the core content of electrochemical research, reveals the quantitative relationship between the reaction rate on the electrode surface and external conditions. In the ruthenium coated titanium electrode system, the kinetic behavior of electrode reactions is significantly affected by the composition and surface structure of the electrode material. Oxygen Evolution Reaction (OER) and Chlorine Evolution Reaction (ClER) are the core reactions of ruthenium-coated titanium electrodes in scenarios such as chlor-alkali industry and water treatment.

Ruthenium coated titanium electrode exhibit superior oxygen evolution catalytic activity at negative potentials, and the redox process on their surface can effectively reduce the reaction overpotential, while ruthenium coated composite coatings show similar activity characteristics for the chlorine evolution reaction.

The occurrence of the oxygen evolution reaction depends on the formation and decomposition of hydroxylated species on the electrode surface, while the chlorine evolution reaction is closely related to the adsorption and activation of chloride ions on the electrode surface. The differences in the kinetic pathways between the two reactions result in their varying sensitivities to the electrolyte composition and PH value. For example, an increase in the concentration of chloride ions will significantly enhance the rate of the chlorine evolution reaction but may inhibit the progress of the oxygen evolution reaction.

Electrocatalytic activity, as a key parameter for evaluating electrode performance, is regulated by multiple factors such as material composition, structural design, and electrolytic environment. From the perspective of material components, the ratio of iridium to ruthenium in the oxide coating directly affects the distribution of active sites and the electronic structure. Studies have shown that coatings with a higher iridium content exhibit a more significant improvement in catalytic activity for the oxygen evolution reaction under alkaline conditions, which is closely related to the high-activity oxide phase formed on their surface.

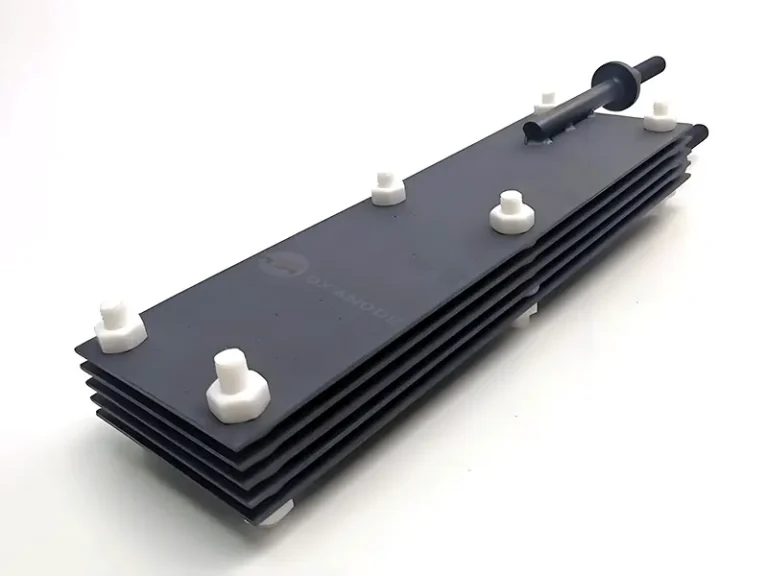

The design of the electrode structure also plays a decisive role in catalytic performance. For example, porous nanostructures can increase the effective reaction area and promote the mass transfer process. In terms of electrolyte properties, parameters such as chloride ion concentration, pH value, and temperature indirectly affect catalytic activity by altering the formation energy barrier or adsorption strength of reaction intermediates. For example, an excessively high chloride ion concentration will exacerbate electrode passivation, while a moderate current density (such as 10.7 mA/cm²) can balance the reaction rate and energy consumption, thereby improving the efficiency of practical applications.

Ruthenium coating preparation technology

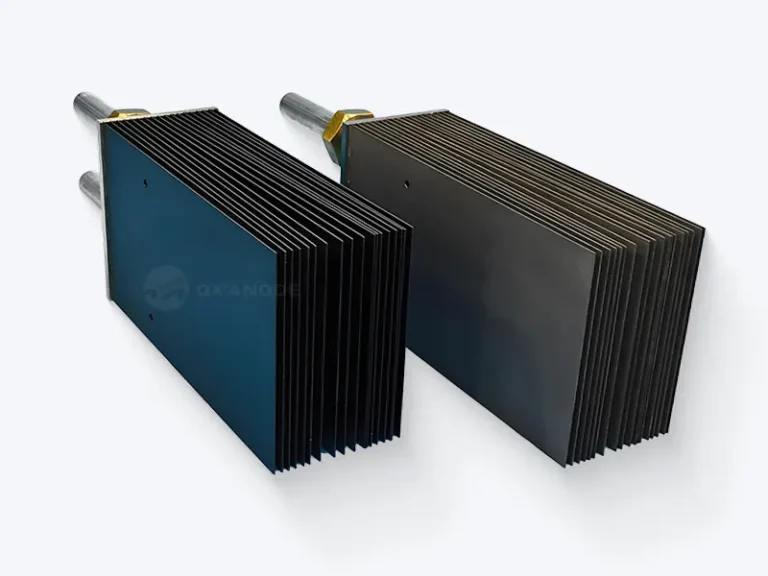

Coating preparation technology is a key link in the industrial application of ruthenium-coated titanium electrodes, whose core lies in achieving the uniform distribution and stable combination of active components on the surface of the substrate through different processes. As a traditional process, the thermal decomposition method involves applying a precursor solution to a titanium substrate and then causing the metal salt to undergo a decomposition reaction under high-temperature conditions to form an oxide or hydroxide coating. This method is relatively simple to operate and can effectively control the coating thickness.

However, high temperature treatment may lead to grain coarsening, affecting the surface activity of the electrode. For instance, in the preparation of titanium-based ruthenium-coated anodes, a mixed solution of ruthenium chloride and chloroiridic acid is often used as the precursor. After heat treatment at 500-600°C, a RuO₂-IrO₂ composite oxide coating is formed, and its crystal phase structure is closely related to the heat treatment temperature.

Ruthenium coated titanium electrode are corrosion-resistant.

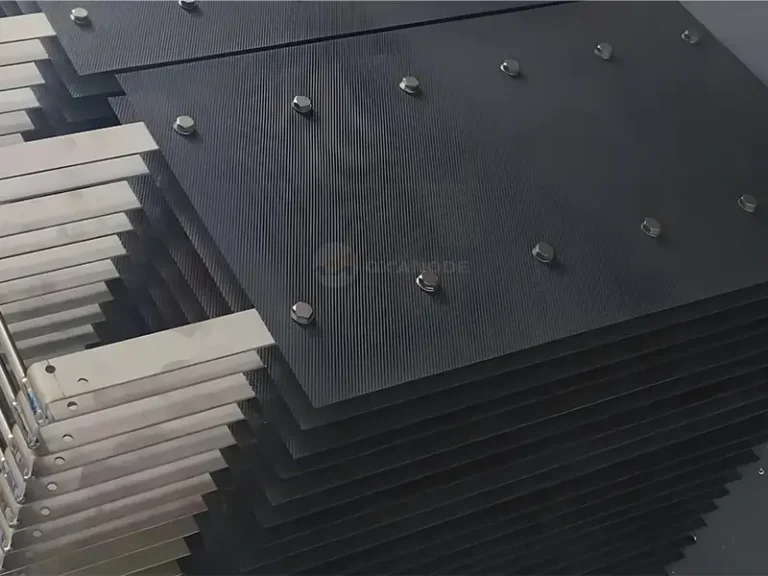

The corrosion resistance of ruthenium-coated titanium electrodes is crucial for their industrial application in harsh environments such as strong acids and alkalis. These electrodes form a stable oxide film through surface modification technology, which effectively inhibits the corrosion reaction of the titanium substrate. The corrosion resistance mechanism of ruthenium-coated titanium electrodes mainly relies on the compactness and chemical inertness of the surface oxide film. The introduction of iridium promotes the lattice reconstruction of the TiO₂ surface layer, forming an Ir-Ti-O solid solution with higher resistance to chlorine corrosion. This oxide film can effectively block the penetration of corrosive media and inhibit the pitting reaction induced by the adsorption of Cl⁻ ions. Meanwhile, the incorporation of ruthenium enhances the electronic conductivity of the oxide film. This synergistic effect stems from the regulatory role of ruthenium on the surface charge distribution, and the oxide layer formed thereby can effectively reduce the local corrosion current density.

In an alkaline medium, the electrocatalytic activity of iridium shows particularly prominent tolerance to the oxygen evolution reaction (OER). The surface oxide layer of the nickel-iridium alloy prepared by electrodeposition exhibits better corrosion resistance than the nickel-ruthenium alloy in 5mol KOH solution. Studies have shown that the incorporation of iridium can optimize the crystal phase structure of the surface oxide film, forming a more stable IrO₂ nanolayer, which has a lower dissolution tendency under alkaline conditions. After the electrode undergoes anodic polarization activation at 100mA/cm², the porosity and defect density of the surface oxide film are significantly reduced, thereby constructing a physical barrier against the penetration of OH⁻ medium. This structural characteristic enables the ruthenium-coated titanium electrode to maintain long-term stability in strong alkaline industrial scenarios such as water electrolysis and seawater desalination.

In practical applications, the corrosion resistance of ruthenium-coated titanium electrodes has been successfully applied in deep-sea extreme environments and wastewater treatment systems. As an anode, the titanium based Ru Ir coated electrode has demonstrated a 90% pollutant removal rate in the treatment of phenol containing wastewater, and its excellent corrosion resistance avoids the iron sludge pollution generated by traditional iron based anodes.

Application of Ruthenium Coated Titanium Electrode

Provide a theoretical basis and technical support for the large scale application of ruthenium coated titanium electrode in the treatment of high concentration, refractory organic wastewater.

Effect of sewage treatment

Phenol wastewater treatment

At current densities of 20-40 mA/cm², the degradation efficiency of difficult-to-degrade organic pollutants such as polycyclic aromatic hydrocarbons, phenols, and dyes is significantly superior to that of traditional metal oxide electrodes.

✓ COD removal rate: 92%±3%

✓ TOC removal rate: >85%

✓ PH stability: the range of change is controlled within ±0.5

✓ Current efficiency: 20%-30% higher than that of traditional Pt/C electrodes

Treatment of nitrobenzene wastewater

Core mechanism: The ruthenium coating composite layer on the electrode surface promotes the generation of hydroxyl radicals (·OH) and accelerates the mineralization process of pollutants.

Initial COD 2800 mg/L, After 4 hours of electrolytic treatment

✓ Final COD: 350 mg/L

✓ COD removal rate: 85.5%

✓ Chroma removal rate: 95%

✓ Deep oxidation: No intermediate products of target pollutants detected

Electrolysis of brine to produce chlorine

Electrolyzed water generates hypochlorous acid (HOCl) and reactive oxygen species (ROS), achieving efficient inactivation of microorganisms in fruits, vegetables, and fresh produce with no residues.

- The killing rate of pathogenic bacteria at 10-20 mA/cm² is > 99.9%

- The residual chlorine in the treated water is less than 0.2 mg/L

- Energy consumption is 40% lower than that of ozone treatment

- Maintain high efficiency in 0.1%-0.5% low-concentration NaCl electrolyte