Titanium anode for sodium hypochlorite generator

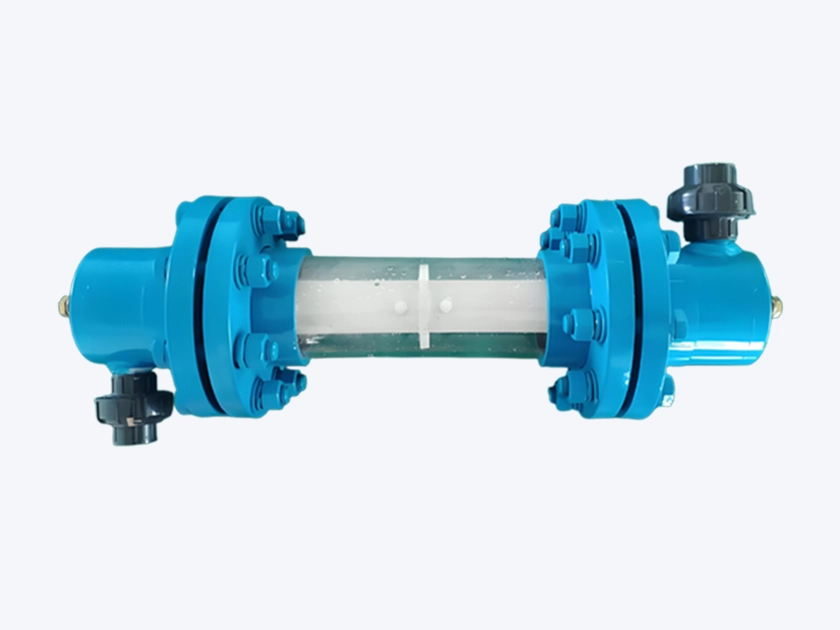

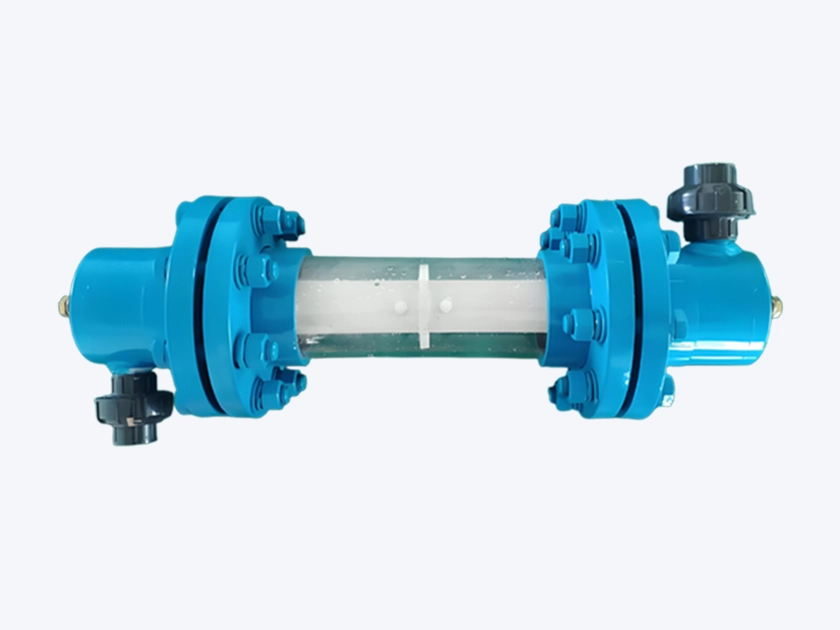

Electrolytic sodium hypochlorite generator

Titanium anode for sodium hypochlorite generator, with their excellent corrosion resistance, good electrical conductivity and high electrochemical activity, significantly enhance the generation efficiency and purity of sodium hypochlorite, while also extending the service life of the equipment. In practical applications, titanium anodes demonstrate the advantages of long service life, stable electrochemical performance and good corrosion resistance, effectively reducing the maintenance costs of the equipment.

Sodium hypochlorite generators, as core water treatment equipment, produce sodium hypochlorite by electrolyzing salt water and are widely used in drinking water disinfection, medical wastewater treatment, and food industry sterilization. Titanium anodes, as an important component of the generators, directly affect the generation efficiency of sodium hypochlorite and the stability of the equipment.

Principles of Titanium anode for sodium hypochlorite generator

The core principle of a sodium hypochlorite generator is to produce sodium hypochlorite (NaClO) by electrolyzing saline water (NaCl solution). The electrochemical reaction process is as follows:

Anode reaction: 2Cl⁻ → Cl₂↑ + 2e⁻

Secondary reaction: Cl₂ + H₂O → HClO (hypochlorous acid) + H⁺ + Cl⁻

Titanium anodes play a dual role in this process:

Catalytic chlorine evolution: By reducing the overpotential for chlorine evolution (approximately 0.2V), the current efficiency is increased to 85%-95%.

Corrosion resistance protection: The noble metal oxide coating on the titanium substrate surface can withstand a strongly corrosive environment with a PH range of 2-7, and its service life exceeds 3 years.

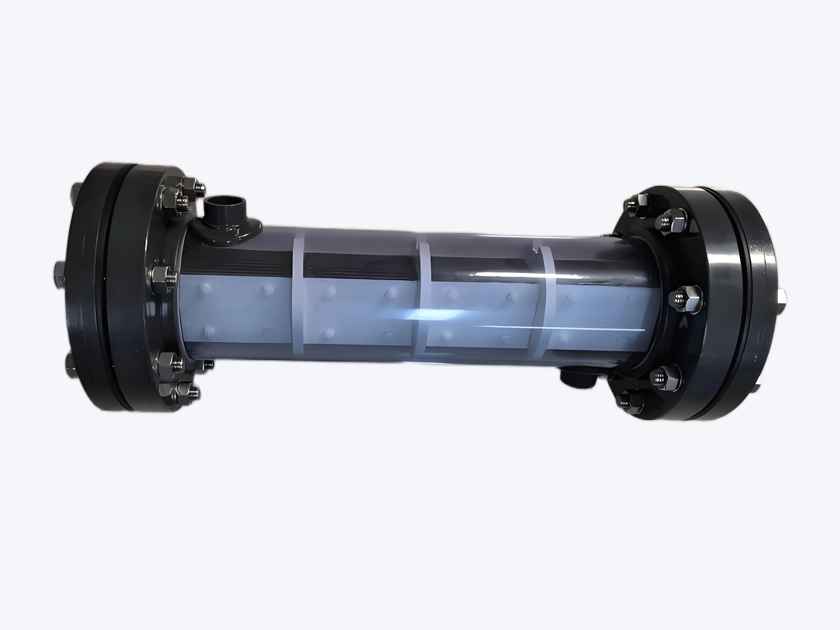

Titanium Anode Materials and Structure

Substrate Treatment: Gr1/Gr2 pure titanium plates are used, and a micro-scale rough surface is formed through sandblasting (particle size 60-120 mesh) and oxalic acid etching processes, which increases the coating adhesion by 40%.

Coating Formulations: The mainstream solutions include:

Ruthenium-Iridium-Titanium ternary system (such as RuO₂-IrO₂-TiO₂): The chlorine evolution potential is as low as 1.13V, and it has excellent reverse polarity resistance.

Gradient composite coating: The bottom layer is a transition layer, and the surface layer is a nanoscale chlorine evolution coating, extending the service life against acid-base impact to 8,000 hours.

Titanium anodes, as the core components of sodium hypochlorite generators, have a decisive impact on the economy and reliability of the overall system through their efficiency and service life during the electrolysis process. This is mainly attributed to the excellent properties of titanium anode materials, including corrosion resistance, good electrical conductivity, and high electrochemical activity.

The corrosion resistance of titanium anodes is one of the key factors for their wide application. During electrolysis, the anode material needs to withstand a strong oxidative environment, while titanium anodes can maintain stable chemical properties in such environments, effectively resisting corrosion and thus extending the service life of the equipment. In addition, titanium anodes have good electrical conductivity, meaning they can efficiently transfer current during electrolysis to improve electrolysis efficiency. Meanwhile, their high electrochemical activity enables titanium anodes to more easily participate in chemical reactions during electrolysis, further enhancing the generation efficiency of sodium hypochlorite.

Sodium hypochlorite generation mechanism

The production process of sodium hypochlorite is a typical electrochemical oxidation reaction, whose core steps involve the oxidation of chloride ions on the anode surface and subsequent aqueous phase reactions. Under electrolytic conditions, chloride ions (Cl⁻) undergo an oxidation reaction at the anode, first generating chlorine gas (Cl₂). This reaction process is significantly influenced by the catalytic activity and surface structure of the anode material. As a key component of the electrolytic cell, the surface characteristics of the titanium anode directly affect the energy barrier and reaction kinetics of chloride ion oxidation.

Current density is a key parameter for regulating production efficiency. At low current densities, the anode reaction is mainly controlled by dynamics, and increasing the current density can linearly increase the output of sodium hypochlorite. However, when the current density exceeds the critical value, the sharp rise in anode overpotential will lead to intensified side reactions. For example, the enhancement of the competitive reaction of oxygen evolution will significantly reduce the selectivity of ClO⁻. The structural design of the titanium anode can effectively broaden the high-efficiency working range. It balances the contradiction between current density and product selectivity by increasing the density of active sites and improving mass transfer conditions. Temperature has a dual impact on the reaction rate: on the one hand, increasing the temperature can accelerate the diffusion of chloride ions and the surface reaction rate, but excessively high temperatures will reduce the viscosity of the electrolyte, which in turn inhibits the convective mass transfer efficiency.

The performance testing of titanium anodes in electrolytic sodium hypochlorite generators is a core link in evaluating their practical application value. It mainly conducts quantitative analysis on the catalytic activity, stability, and energy efficiency of the electrodes through key indicators such as current efficiency and cell voltage. Current efficiency is an important parameter for measuring the ratio of the actual production amount of the target product to the theoretical yield in the electrolysis process. Its calculation is based on Faraday’s law, derived by comparing the actual concentration of sodium hypochlorite produced with the theoretical calculation value, combined with the total electricity consumption during the electrolysis process.

Influencing factors of titanium anodes for sodium hypochlorite generators

In the application of titanium anodes in electrolytic sodium hypochlorite generators, their performance is affected by various external conditions, among which electrolyte concentration and temperature are two key factors. The adjustment of electrolyte concentration directly affects the ion migration rate and reaction interface kinetics. In a typical NaCl electrolysis system, when the concentration is lower than 2%, insufficient ionic conductivity leads to an increase in polarization voltage, a decrease in the utilization rate of active sites for the chlorine evolution reaction (CER), and a significant reduction in current efficiency (CE). As the concentration increases to 4% – 6%, the conductivity of the solution enhances, the migration resistance of chloride ions decreases, and the catalytic efficiency of active substances (such as ruthenium-iridium oxide coatings) on the surface of the titanium anode is fully exerted, with the sodium hypochlorite yield reaching more than 85% of the theoretical value. However, when the concentration is too high (e.g., exceeding 10%), concentration polarization intensifies, the competitive adsorption of side reactions (such as oxygen evolution reaction) enhances, and the decomposition rate of the precipitated sodium hypochlorite in a high-salt environment accelerates, ultimately leading to a decrease in yield and CE. Electrochemical impedance spectroscopy (EIS) tests show that the double-layer resistance on the electrode surface increases at high concentrations, inhibiting the electron transfer process, which is consistent with the trend of activity coefficient changes predicted by the Nernst equation.

The effect of temperature on the performance of titanium anodes exhibits non-linear characteristics. In a low-temperature environment (<20°C), the ion diffusion coefficient decreases, the kinetics of the chlorine evolution reaction are slow, the stability of the passive film on the surface of the titanium anode is enhanced, but the overall current density is limited. When the temperature rises to 30–40°C, the accelerated thermal motion of molecules significantly improves mass transfer efficiency. The stress relaxation effect at the interface between the titanium substrate and the coating weakens the propagation of microcracks, and the concentration gradient of Cl⁻ accumulated on the electrode surface decreases, which reduces the CER overpotential by 15%–20% and increases the yield by about 30%. However, when the temperature exceeds 50°C, the activation energy of the sodium hypochlorite decomposition reaction is exceeded, and the potential difference between the oxygen evolution reaction (OER) and CER narrows, leading to a decrease in selectivity. In addition, high temperatures will accelerate the phase transformation of oxides on the surface of the titanium anode. For example, the transformation of RuO₂ from rutile to orthorhombic structure will reduce its conductivity. At the same time, Cl⁻ in the chloride solution may undergo a corrosive displacement reaction with the oxide, increasing the risk of coating peeling. Cyclic voltammetry tests show that the Tafel slope of the titanium anode increases by 40% at 60°C, indicating that the activity of the oxygen evolution side reaction is significantly enhanced.

Say Hello

Get In Touch

Don’t Hesitate to contact Us anytime with questions.