Application of PbO₂ titanium electrode in copper electrowinning

Electrowinning of copper, as a key process in the production of high-purity copper, is widely used in the electronics, new energy, and chemical industries.

Traditional lead-based anodes have problems such as low electrolysis efficiency (current efficiency is only 85%-90%) and serious environmental pollution (electrolyte pollution caused by lead ion dissolution). In contrast, titanium-based PbO₂ anodes, with their excellent electrical conductivity (resistivity of 6×10⁻⁵ Ω·cm), corrosion resistance (corrosion rate lower than 1/10 of that of lead anodes), and environmental protection characteristics, have gradually become an alternative in the industry.

Electrochemical Properties of PbO₂ Titanium Electrode

- Oxygen evolution overpotential

The oxygen evolution potential of the PbO₂ titanium electrode is as high as 1.75 V (vs. SCE), which can effectively inhibit side reactions (such as oxygen evolution) and increase the current efficiency of copper deposition to 93%-95%. - Corrosion resistance performance

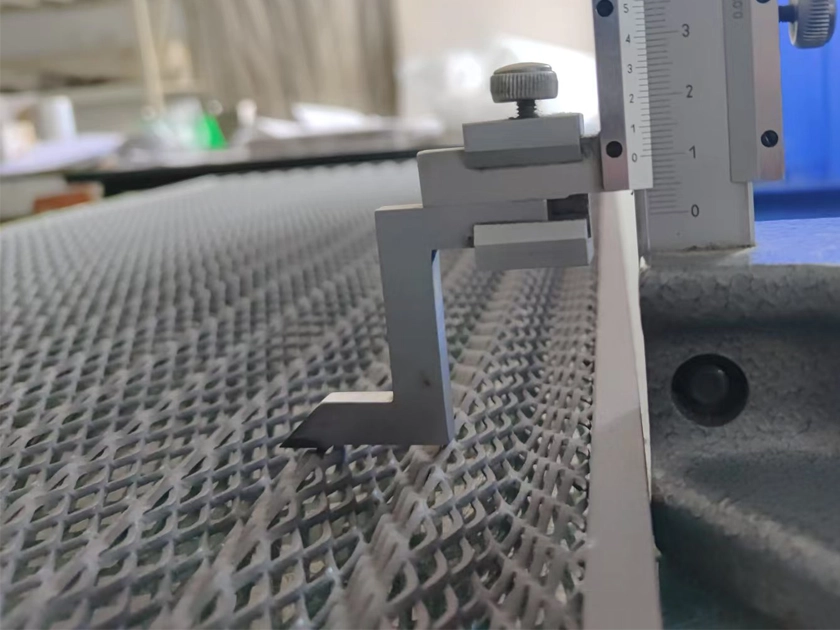

In a copper sulfate electrolyte (Cu²⁺ 40-50 g/L, H₂SO₄ 150-200 g/L, temperature 50-60℃), the corrosion rate of the PbO₂ titanium Electrode is less than 1/10 of that of the traditional lead anode. - Electrical conductivity and mechanical strength

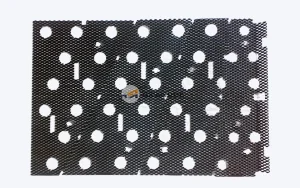

The conductivity of β-PbO₂ is close to that of metallic lead, but its hardness is relatively low (Martens hardness 200-300 HV). Through the design of composite coatings (such as α-PbO₂/β-PbO₂ double-layer structure), both conductivity and wear resistance can be achieved, making it suitable for working conditions with high current density (>500 A/m²).

Industrial application of PbO₂ titanium electrode in copper electrowinning

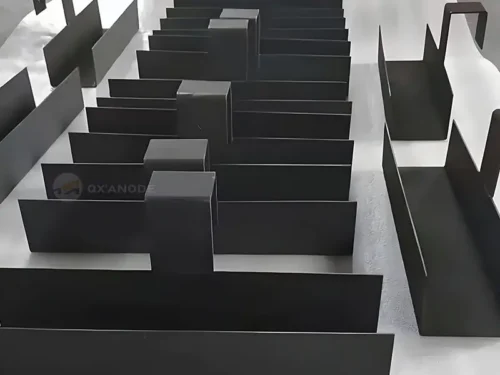

PbO₂ titanium electrode serve as anodes in the copper electrowinning process. Their working principle is to utilize their high oxygen evolution potential and good electrical conductivity to stably provide oxidation reaction sites in an acidic electrolyte system. In coordination with the copper ion reduction reaction at the cathode, they enable efficient copper electrodeposition.

The lead dioxide coating is the core layer of the reaction. The β-PbO₂ crystal form has excellent electronic conductivity and oxygen evolution catalytic activity, while the α-PbO₂ crystal form enhances the bonding force between the coating and the titanium substrate as well as the corrosion resistance.

The electrolyte for electrowon copper is a copper sulfate system. After being electrified, the current is conducted through the titanium substrate to the lead dioxide coating. At the anode, the oxidation of water and oxygen evolution reaction occurs instead of the dissolution of the anode material (this is the core difference from the traditional soluble lead anode). The reaction equation is:

2H₂O−4e−=O₂↑+4H+

The electrons generated at the anode are transferred to the cathode through the external circuit. The Cu²⁺ in the electrolyte gains electrons on the cathode surface, is reduced to metallic copper, and deposits. The reaction equation is:

Cu2++2e−=Cu↓

The oxygen evolution potential of the lead titanium dioxide electrode is ≥1.70V, which is much higher than that of the traditional lead anode (about 1.55V). The high oxygen evolution potential can inhibit side reactions (such as sulfate oxidation) and reduce ineffective energy consumption.

The high oxygen evolution potential reduces the energy consumption of anode side reactions, allowing more electrical energy to be used for the reduction of Cu²⁺. Meanwhile, the stable anode surface enables a more uniform and dense deposition of cathode copper.

Charge and mass balance of the system

During the electrowinning process, the H⁺ generated at the anode replenishes the hydrogen ions consumed by the cathodic reaction in the electrolyte, maintaining the stability of the electrolyte’s acidity; sulfate ions act as charge carriers in the electrolyte, enabling ion migration and ensuring the charge balance of the entire electrolytic system.

The corrosion resistance of PbO₂ titanium electrode enables them to work stably for a long time under high-concentration sulfuric acid (such as 170g/L) and a certain current density (180-210A/m²), without causing electrode failure due to coating detachment or substrate corrosion.

Manufacturer of PbO₂ Titanium Electrode

Qixin Titanium is a manufacturer of titanium anodes from China., focusing on the R&D, manufacturing and application of MMO coated titanium anodes.

Qi Xin Titanium was founded in 2006., with over 20 years of manufacturing experience, we provide stable and reliable titanium anode products suitable for multiple scenarios. We help enterprises improve electrolysis efficiency, reduce operating costs, and offer personalized customization to ensure long-term stable operation.