Titanium anode for ammonia nitrogen wastewater treatment

An efficient, environmentally friendly, and stable electrochemical water treatment solution to facilitate the sustainable development of the aquatic ecological environment

Working principle of titanium anode for ammonia nitrogen wastewater treatment

The working principle of titanium anode used in ammonia nitrogen wastewater treatment is based on electrochemical reactions, which achieve the degradation of ammonia-nitrogen through two pathways: direct oxidation and indirect oxidation.

- In the direct oxidation process, ammonia nitrogen molecules (NH₃ or NH₄⁺) lose electrons directly on the surface of the titanium anode, undergoing an oxidation reaction. Taking NH₄⁺ as an example, the reaction equation on the surface of the titanium anode is:

2 NH₄⁺ – 6 e⁻ + 6 OH⁻ ⟶ N₂ + 8 H₂O

During the electrolysis process, the precious metal oxide coating on the surface of the titanium anode used for ammonia nitrogen wastewater treatment plays an important electrocatalytic role. The active sites in the coating can adsorb ammonia nitrogen molecules, reduce the activation energy of the reaction, promote the directional transfer of electrons, and accelerate the oxidation reaction rate of ammonia nitrogen.

The efficiency of direct oxidation is highly dependent on the catalytic activity and electron conduction performance of the titanium anode coating. The higher the catalytic activity of the coating and the smoother the electron conduction, the easier the direct oxidation reaction of ammonia nitrogen becomes. - Indirect oxidation achieves the degradation of ammonia nitrogen through strong oxidizing intermediates generated by anodic reactions. When chloride ions (Cl⁻) are present in the electrolyte, the chloride ions are oxidized on the anode surface to form chlorine gas (Cl₂).

2Cl–-2e–⟶Cl₂

Chlorine gas will further react with water to form hypochlorous acid (capital H capital C l capital O) and hydrochloric acid (capital H capital Cl).

Cl₂+H₂O⟶HClO+HCl

Hypochlorous acid is a strong oxidizing agent that can react with ammonia nitrogen, oxidizing it into harmless substances such as nitrogen gas.

In the electrolyte, water molecules, under the catalytic action of a specific coating, will generate hydroxyl radicals (·OH) with extremely strong oxidizing properties.

H₂O-e–⟶⋅OH+H⁺

Hydroxyl radicals have an extremely high oxidation potential and can react non-selectively with ammonia nitrogen and other organic pollutants, rapidly oxidizing and decomposing them. The generation and reaction processes of these strong oxidizing intermediates are affected by various factors such as electrolyte composition, pH value, and current density.

The higher the concentration of chloride ions in the electrolyte, the greater the amount of chlorine gas and hypochlorous acid produced, and the stronger the indirect oxidation capacity; while an appropriate pH value and current density can promote the generation and reaction of strong oxidizing intermediates, thereby improving the degradation efficiency of ammonia nitrogen.

Electrochemical Performance of Titanium Anodes for Ammonia Nitrogen Wastewater Treatment

The conventional range of operating current density is 100A/m² – 1000A/m², which needs to be adjusted according to the application scenario. In ammonia nitrogen wastewater treatment, for high-concentration ammonia nitrogen wastewater, the current density can be appropriately increased to accelerate the reaction rate and improve the ammonia nitrogen removal efficiency; for low-concentration ammonia nitrogen wastewater, a lower current density can meet the treatment requirements and avoid excessive consumption of electrical energy. For example, when treating high-concentration ammonia nitrogen industrial wastewater, the current density can be set at 500A/m²; when treating ammonia nitrogen in low-concentration domestic sewage, the current density can be controlled at 100A/m².

The limiting current density is ≥1000A/m², which is an indicator of short-term overload capacity. Exceeding the limiting current density may easily lead to coating burnout, causing the electrode to lose its catalytic activity. In actual operation, the current density should be prevented from exceeding the limit value for a long time to ensure the stability and service life of the electrode.

In terms of operating voltage, it depends on factors such as electrolyte concentration, temperature, and current density. In ammonia nitrogen wastewater treatment, when the electrolyte concentration is high and the current density is large, the cell voltage will increase accordingly. Reasonable control of the operating voltage can not only ensure the smooth progress of electrochemical reactions but also reduce energy consumption.

The hazards of ammonia nitrogen wastewater

Ammonia nitrogen wastewater covers multiple fields such as industry, agriculture, and daily life. In industrial production, many industries including chemical engineering, pharmaceuticals, fertilizers, food processing, textile printing and dyeing, leather manufacturing, and electronic electroplating generate a large amount of ammonia-nitrogen-containing wastewater during their production processes. For example, in the chemical industry, during the production of products like synthetic ammonia and urea, a large amount of ammonia nitrogen enters wastewater in the form of raw material residues, intermediate products, or by-products; in the pharmaceutical industry, high-concentration ammonia-nitrogen wastewater is also produced in process links such as drug synthesis and fermentation. If these industrial wastewaters are directly discharged without effective treatment, they will cause serious pollution to the surrounding water environment.

Ammonia nitrogen also has a direct toxic effect on aquatic organisms. Ammonia nitrogen in water mainly exists in two forms: free ammonia (NH₃) and ammonium ions (NH₄⁺), among which the toxicity of free ammonia to aquatic organisms is far greater than that of ammonium ions. Free ammonia can penetrate the cell membranes of aquatic organisms, interfere with their internal acid-base balance and ion balance, and affect the normal metabolism and physiological functions of cells. In an environment with high concentrations of ammonia nitrogen, aquatic organisms will experience problems such as slow growth, decreased immunity, and reduced reproductive capacity, and in severe cases, it can even lead to death. Different species of aquatic organisms have different tolerance to ammonia nitrogen. Some sensitive aquatic organisms such as fish and shrimp will be significantly affected in water with slightly higher ammonia nitrogen concentrations.

Application of Titanium Anodes in Ammonia Nitrogen Sewage Treatment

In view of the characteristics of ammonia-nitrogen wastewater in chemical industrial parks, an electrochemical oxidation treatment process with titanium anode as the core is adopted, combined with pretreatment and post-treatment processes, forming a complete wastewater treatment system.

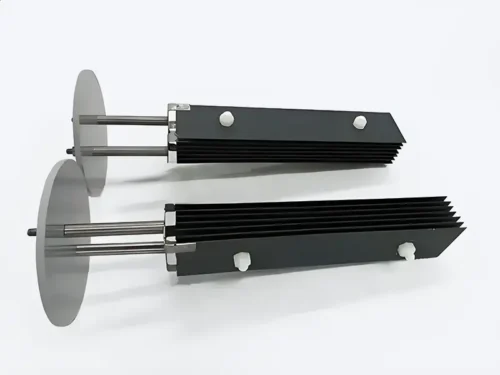

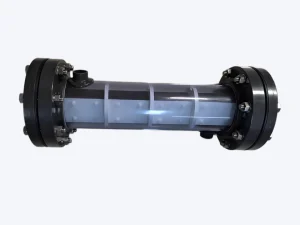

This project uses dimensionally stable titanium anodes, whose base material is industrial pure titanium Gr1, which has good corrosion resistance and mechanical properties. A ruthenium-iridium-titanium oxide coating is applied to the surface of the titanium substrate, prepared by the thermal decomposition method, with the coating thickness controlled between 8 – 12μm. This coating has excellent electrocatalytic activity and stability, which can effectively promote the oxidation reaction of ammonia nitrogen. The electrolytic cell adopts a rectangular structure, made of corrosion-resistant fiberglass reinforced plastic, with multiple sets of titanium anodes and cathodes arranged inside, and the anodes and cathodes are staggered to improve electrolysis efficiency. The electrode spacing is designed to be 5mm, which not only ensures good mass transfer effect but also reduces energy consumption.

In the preprocessing stage, large granular suspended solids and impurities in the sewage are first removed through a grid to prevent them from clogging subsequent treatment equipment. Then, the sewage is introduced into a regulating tank, where an aeration and stirring device is installed to balance the water quality and quantity, making the PH value, temperature, and pollutant concentration of the sewage tend to be stable. Next, the air flotation method is used to further remove suspended solids and some organic matter from the sewage. By introducing high-pressure dissolved air water into the sewage, a large number of tiny bubbles are generated, causing the suspended solids and organic matter to attach to the bubbles and float to the water surface, thereby achieving solid-liquid separation.

The pretreated sewage enters the electrolytic cell for electrochemical oxidation treatment. During the electrolysis process, the titanium anode acts as the anode. Under the action of a direct current electric field, oxidation reactions occur on its surface, generating strong oxidizing active substances such as hydroxyl radicals (·OH), chlorine gas (Cl₂), etc. These active substances can oxidize ammonia nitrogen into harmless substances such as nitrogen gas and nitrate, and at the same time degrade organic pollutants in the sewage. By controlling the current density to be 300 – 500 A/m² and the electrolysis time to be 60 – 90 minutes, ammonia nitrogen and COD can be effectively removed.

After electrolysis, the sewage enters the post-treatment stage. First, it passes through a neutralization tank to adjust the pH value to neutral, then enters a sedimentation tank for sedimentation to remove suspended solids and sediments from the water. Next, an activated carbon adsorption process is used to further remove residual organic matter and heavy metal ions from the water. Through the adsorption of activated carbon, the concentration of pollutants in the sewage is further reduced.

Advantages of titanium anode for Ammonia Nitrogen Wastewater Treatment

- Efficient ammonia nitrogen removal capacity

Titanium anode for ammonia nitrogen wastewater treatment can achieve efficient removal of ammonia nitrogen in a relatively short period of time through electrochemical oxidation. In an ammonia nitrogen wastewater treatment project in a certain chemical industrial park, the ammonia nitrogen concentration in the raw water was as high as 1500 – 2500mg/L. After adopting the titanium anode treatment process, under the conditions of a current density of 300 – 500A/m² and an electrolysis time of 60 – 90min, the ammonia nitrogen removal rate reached 99.5%, and the ammonia nitrogen concentration in the effluent dropped to below 10mg/L. Titanium anodes can quickly reduce the ammonia nitrogen concentration and reduce harm to the environment. - Stability and durability

Titanium anode for ammonia nitrogen wastewater treatment have good stability and durability. Ammonia-nitrogen wastewater often contains various corrosive substances, such as chloride ions, sulfate ions, heavy metal ions, and acidic or alkaline substances. These substances can cause severe corrosion and passivation of ordinary electrode materials, leading to a decline in electrode performance or even failure.

In aquaculture wastewater treatment projects, aquaculture wastewater contains high concentrations of ammonia nitrogen, organic matter, and a small amount of heavy metal ions, with complex water quality and strong corrosiveness. When using Ruo₂-IrO₂ titanium anodes for treatment, after long-term operation, the coating on the electrode surface remains intact without obvious corrosion or passivation, and the ammonia nitrogen removal effect is stable. - Highly adaptable

Titanium anode for ammonia nitrogen wastewater treatment have wide adaptability to ammonia nitrogen wastewater with different concentrations and water qualities. Whether it is high-concentration industrial ammonia nitrogen wastewater, such as wastewater from industries like chemical fertilizers, coking, and petrochemicals with ammonia nitrogen concentrations as high as several thousand mg/L, or low-concentration domestic sewage and aquaculture wastewater, titanium anodes can play an effective treatment role.

Manufacturer of titanium anode for ammonia nitrogen wastewater treatment

Qixin Titanium is a manufacturer of titanium anodes from China., focusing on the R&D, manufacturing and application of MMO coated titanium anodes.

Qi Xin Titanium was founded in 2006., with over 20 years of manufacturing experience, we provide stable and reliable titanium anode products suitable for multiple scenarios. We help enterprises improve electrolysis efficiency, reduce operating costs, and offer personalized customization to ensure long-term stable operation.