High Performance Titanium Anode

Leading manufacturer of premium mixed metal oxide coated titanium anode for industrial electrochemical processes and water treatment applications.

About Our Company

We’re from the

MMo titanium anodes

factory in China.

Qixin Titanium Anodes Co., Ltd. established in 2006, it is a high – tech enterprise with profound influence in the field of titanium anodes in China.

Why Choose Our Titanium Anode

Our anodes are engineered for superior performance, longevity, and efficiency in the most demanding industrial applications.

Experienced

With 20 years of production experience, we refine every process and deliver stability through solid strength.

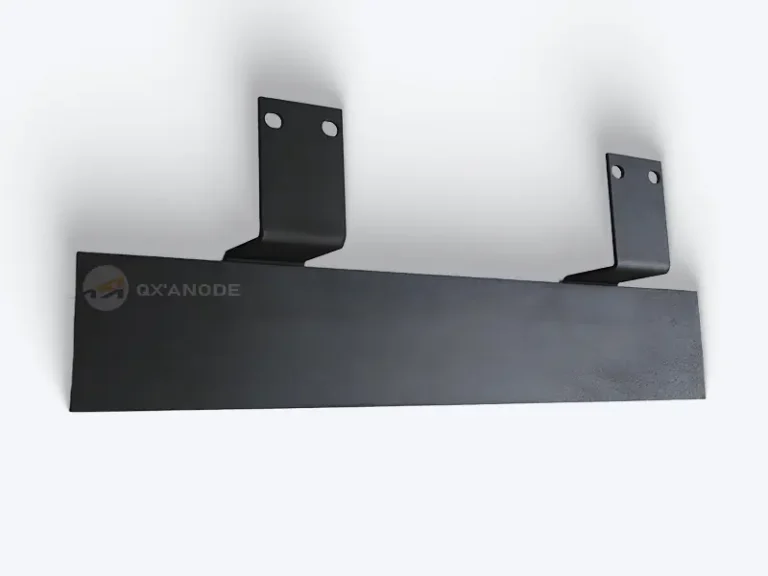

Custom Solutions

Tailored anode designs to meet your specific industrial requirements and operational conditions.

Quality Assurance

Every anode undergoes rigorous testing to ensure compliance with international quality standards.

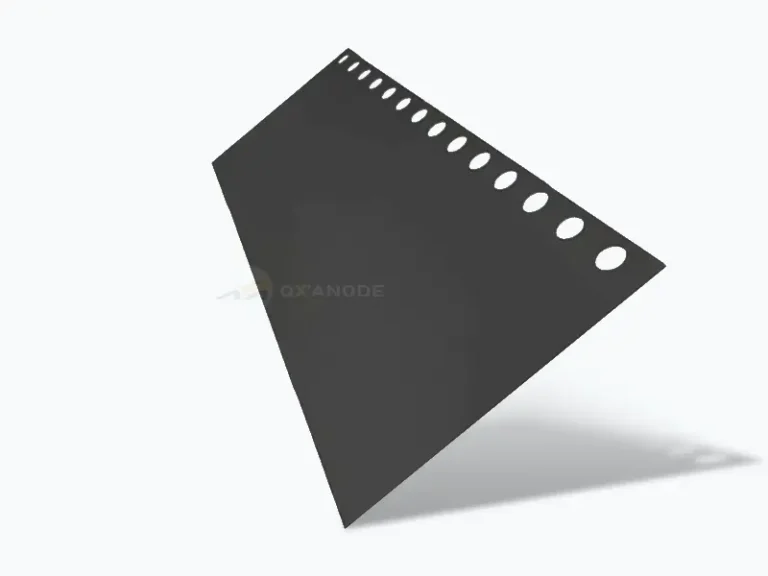

TITANIUM ANODE PRODUCT

Industrial Applications

Manufacturer of MMO titanium anode

Suitable for electroplating and water treatment applications.

OUR SERVICES

What We Offer &What We Do.

With over 20 years of production experience

we supply MMO titanium anodes (Mixed Metal Oxide) with stable quality for the electrochemical industry.

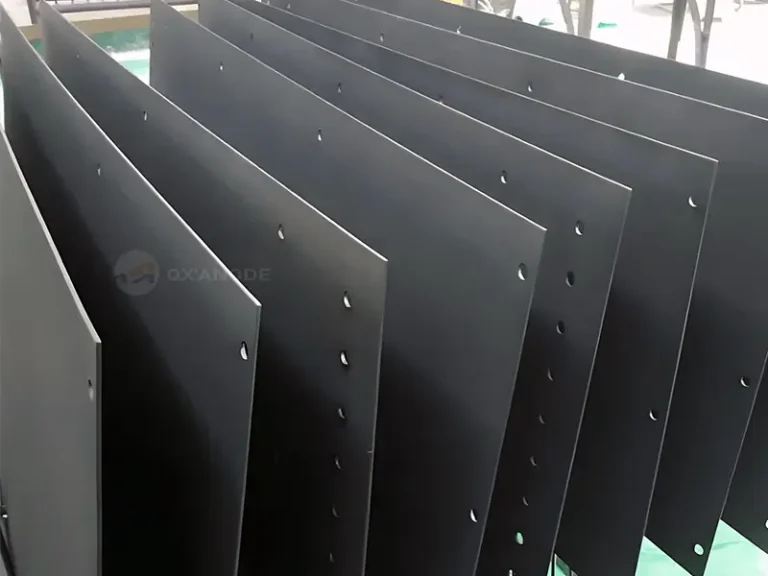

Manufacturing process of mmo titanium anode

The manufacturing process of MMO titanium anode generally includes substrate selection and processing, surface treatment, anode coating, sintering and hardening, activity activation, cleaning and inspection, etc.

Base material preparation

- Selection of base materialsIndustrial pure titanium (grades GR1 and GR2) is selected, with a purity of over 99.5%, featuring low density and moderate mechanical strength.

- Pretreatment process

Including sandblasting, degreasing, pickling and etching, as well as water washing and drying, to ensure the surface is clean and enhance coating adhesion.

Quality Inspection

- Coating adhesion

Tested by “grid method” or “bend test”. - enhance lifespan

accelerated corrosion test - Appearance and Size

Check the uniformity of the coating and the size of the substrate.

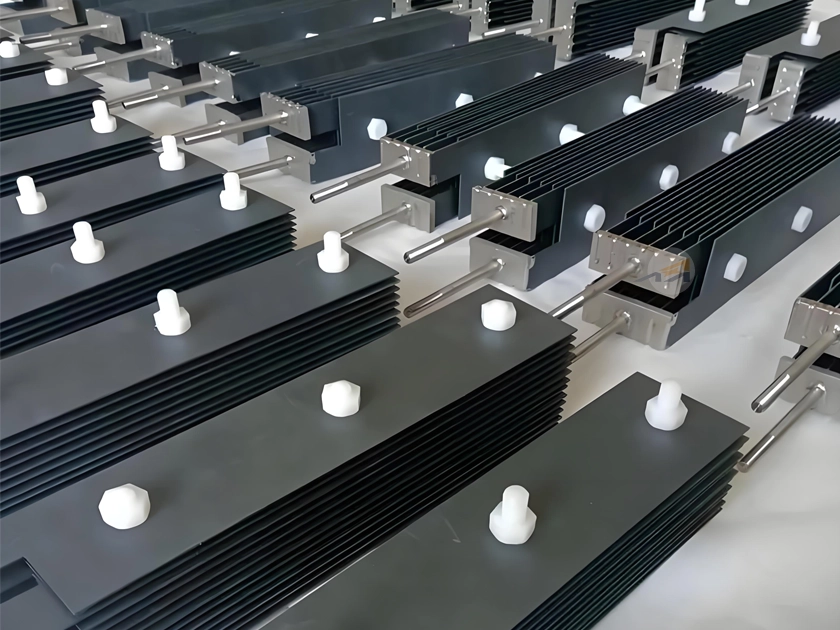

Coating preparation

Coating preparation is the core of titanium anode manufacturing. Taking “preparation of RuO₂-IrO₂ coating by thermal decomposition method” as an example, the main steps include:

- Preparation of Coating Solution

Dissolve the active metal precursor in a solvent according to the designed ratio, and add a small amount of binder to adjust the viscosity. - Coating, drying and heat treatment

Apply by brushing, dry at 80-120℃, heat treat at 400-500℃, and repeat the operation 8-12 times. - sintering

Heat preservation at 500-550°C for 30-60 minutes to promote crystal growth and densification of the coating.

MMO titanium anode History

Since 1967, a method for forming a metal oxide film on the surface of titanium metal has been invented. One of the ruthenium oxide coatings is used in the electrolysis of brine, which has greatly promoted the transformation of the chlor-alkali industry. To this day, it is still widely used in the electrochemical reaction of chlorine gas evolution.

In the 1970s, iridium tantalum mixed metal oxide coatings were successfully developed and gradually began to be used in electrochemical oxygen evolution reactions. Today, titanium anodes are widely used in many electrochemical fields due to their superior performance.

MMO anodes can be classified according to the different coating metals into ruthenium-iridium-titanium anodes (chlorine evolution anodes), iridium-tantalum-titanium anodes (oxygen evolution anodes), platinum-titanium anodes, and lead dioxide titanium anodes.

TESTIMONIALS

What Clients Say?

Titanium Anode Technology

The Core Driving Force for High Quality Development of the Electrolysis Industry

The optimal combination of substrate and coating achieves a dual improvement in catalytic performance and service life.

The Application of Titanium Anode in Sodium Hypochlorite Generators

Titanium anode: the core component of sodium hypochlorite generator During the electrolysis of sodium chloride solution, the titanium anode increases…

MMO coated titanium anodes

MMO coated titanium anodes have excellent electrochemical performance, with low chlorine evolution and oxygen evolution potentials, stable cell voltage, and can effectively reduce energy consumption during the electrolysis process.

Iridium-Tantalum-Titanium Anode

Applications of Iridium-Tantalum-Titanium Anode Iridium-tantalum-titanium anode, as core electrode materials in the electrochemical industry, rely on their high catalytic activity…