Application of Lead Dioxide Titanium Anodes in Water Treatment

The new generation of electrochemical water treatment technology solves the problem of water resource pollution and promotes sustainable development.

With the acceleration of industrialization, the efficient utilization of water resources and metal resources, as well as environmental protection, have become urgent issues to be addressed. As a high-performance electrode material, lead dioxide-titanium anodes have shown great potential in the fields of water treatment and hydrometallurgy due to their excellent electrochemical performance and corrosion resistance.

Working principle

The working principle of the lead titanate dioxide anode in water treatment is mainly based on the degradation of water pollutants by the strongly oxidizing substances generated during the electrochemical reaction. When an external voltage is applied to an aqueous solution containing pollutants, the lead dioxide titanium anode undergoes an oxidation reaction as the anode. Due to the high oxygen evolution potential of lead dioxide, at the anode surface, water molecules are first oxidized to generate oxygen and hydrogen ions. The reaction equation is: 2H₂O – 4e⁻ = O₂↑ + 4H⁺. In this process, because of the high oxygen evolution overpotential of lead dioxide, the reaction of water molecule oxidation to generate oxygen requires a relatively high potential to occur, which provides conditions for the occurrence of other oxidation reactions.

A series of strongly oxidizing intermediate products, such as hydroxyl radicals (·OH), are also generated on the anode surface. These strongly oxidizing substances can react with pollutants in the water, degrading them into small – molecule substances or even completely mineralizing them into carbon dioxide and water. Taking the degradation of organic matter as an example, hydroxyl radicals have an extremely high oxidation potential (E⁰(·OH/OH⁻)=2.80V). They can interact with organic molecules through reaction methods such as hydrogen abstraction and addition. For aromatic organic compounds, hydroxyl radicals first attack the positions with higher electron cloud density on the benzene ring, forming hydroxyl – substituted intermediates. Then the intermediates further undergo ring – opening, oxidation and other reactions, gradually degrading into small – molecule organic acids, such as formic acid and acetic acid. Eventually, these small – molecule organic acids are completely oxidized to carbon dioxide and water.

For heavy metal ions in water, the lead titanate dioxide anode can also play a certain treatment role. During the electrochemical reaction process, heavy metal ions move towards the cathode under the action of the electric field and are reduced to metal at the cathode surface, thus being removed from the water. For some heavy metal ions with variable valence states, such as Cr³⁺, the lead titanate dioxide anode can oxidize it to the high – valence state of Cr₂O₇²⁻. Then, by adjusting the pH value of the solution, Cr₂O₇²⁻ can be separated from the water in the form of a precipitate. This method of electrochemical treatment using the lead titanate dioxide anode has the advantages of high efficiency, environmental friendliness, and no secondary pollution, showing good application prospects in the field of water treatment.

“Water, as the source of life, is an indispensable material foundation for human survival and social development. However, with the acceleration of global industrialization and urbanization, a large amount of untreated industrial wastewater, domestic sewage, and agricultural non-point source pollution have been discharged into water bodies. This has led to increasingly severe problems of water resource scarcity and water pollution, posing a huge threat to the ecological environment and human health.”

As a new type of insoluble metal oxide anode material, lead dioxide – titanium anode (PbO₂/Ti) has shown great application potential in the field of water treatment in recent years. Titanium (Ti) is widely used as the substrate of the PbO₂ electrode due to its good corrosion resistance and a coefficient of thermal expansion close to that of PbO₂.

- High oxygen evolution overpotentialIt can effectively oxidize water pollutants with low energy consumption.

- Strong corrosion resistanceIt has a long service life, which can reduce the frequency of electrode replacement and lower the operating cost.

- Electrical conductivity and catalytic activityCan improve reaction rate and processing efficiency

Lead Dioxide Titanium Anodes

Among various water treatment technologies, electrochemical water treatment technology has received extensive attention due to its advantages such as high efficiency, environmental friendliness, and simple operation. This technology mainly utilizes the electrochemical reactions occurring at the interface between the electrode and the solution to achieve the degradation, oxidation, reduction, or separation of pollutants in water. The anode, as a key component of the electrochemical water treatment system, its performance directly affects the treatment effect and energy consumption of the entire system. Traditional anode materials, such as graphite, lead alloys, etc., have many limitations in practical applications. Although graphite anodes are inexpensive, they have low mechanical strength and are prone to corrosion. They will gradually wear out during use, resulting in a short electrode lifespan, and the generated graphite debris will cause secondary pollution to the water body. Lead alloy anodes are toxic, and lead ions may dissolve out during the electrolysis process, polluting the water body. At the same time, their electrocatalytic activity is relatively low, and the oxygen evolution overpotential is high, resulting in high energy consumption. These limitations seriously restrict the further application and development of traditional anode materials in the field of water treatment.

As a new type of insoluble metal oxide anode material, lead dioxide – titanium anode (PbO₂/Ti) has shown great application potential in the field of water treatment in recent years. Titanium (Ti) is widely used as the substrate of the PbO₂ electrode due to its good corrosion resistance and a coefficient of thermal expansion close to that of PbO₂. PbO₂ itself has characteristics such as good electrical conductivity, high oxygen evolution over – potential, and good catalytic performance, making it an excellent anodic active material. The PbO₂/Ti anode combines the stability of the titanium substrate and the excellent electro – catalytic performance of lead dioxide. It has a high oxygen evolution over – potential, enabling the effective oxidation of pollutants in water at low energy consumption. At the same time, it has strong corrosion resistance and a long service life, which can reduce the frequency of electrode replacement and lower the operating cost. In addition, this anode also has good electrical conductivity and electro – catalytic activity, which can increase the reaction rate and treatment efficiency. Therefore, studying the application of the lead dioxide – titanium anode in water treatment is of great practical significance for promoting the development of electrochemical water treatment technology and solving the increasingly severe water pollution problem. It can not only provide more efficient and reliable technical support for actual water treatment projects, but also help promote the sustainable utilization of water resources and achieve the coordinated development of the economy, society, and the environment.

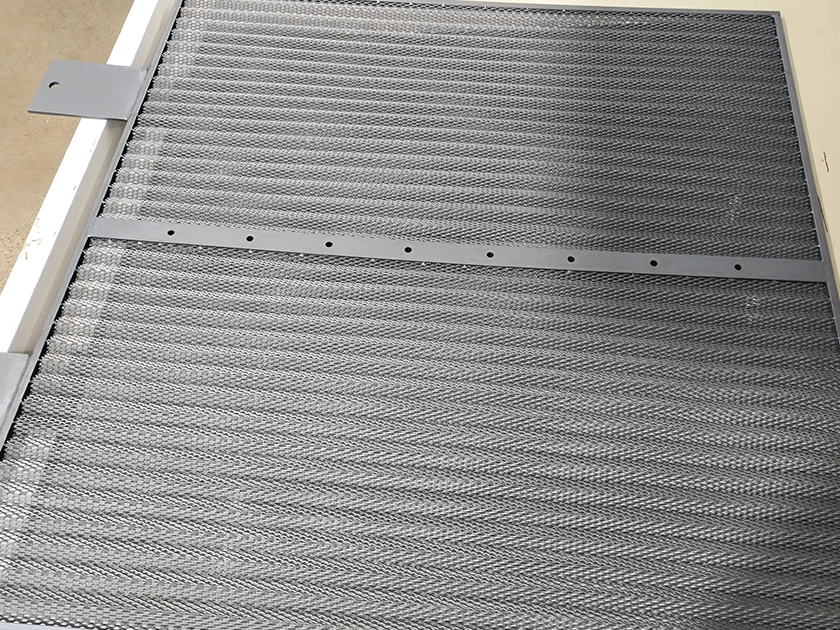

Structure and Composition of Lead Dioxide-Titanium Anodes

The lead dioxide titanium anode is mainly composed of three parts: the titanium substrate, the underlying layer, and the lead dioxide active layer. The titanium substrate, as a supporting structure, provides mechanical strength and stability for the entire anode. Titanium has the advantages of low density, high strength, and strong corrosion resistance, and its surface can form a good bond with the underlying layer and the active layer. In practical applications, industrial pure titanium or titanium alloys are often selected as the substrate materials. The purity of different titanium materials and the content of alloying elements will affect the performance of the substrate, and thus have a certain impact on the overall performance of the anode. For example, a titanium alloy substrate containing a small amount of palladium element can exhibit more excellent corrosion resistance in some highly corrosive environments, thereby extending the service life of the anode.