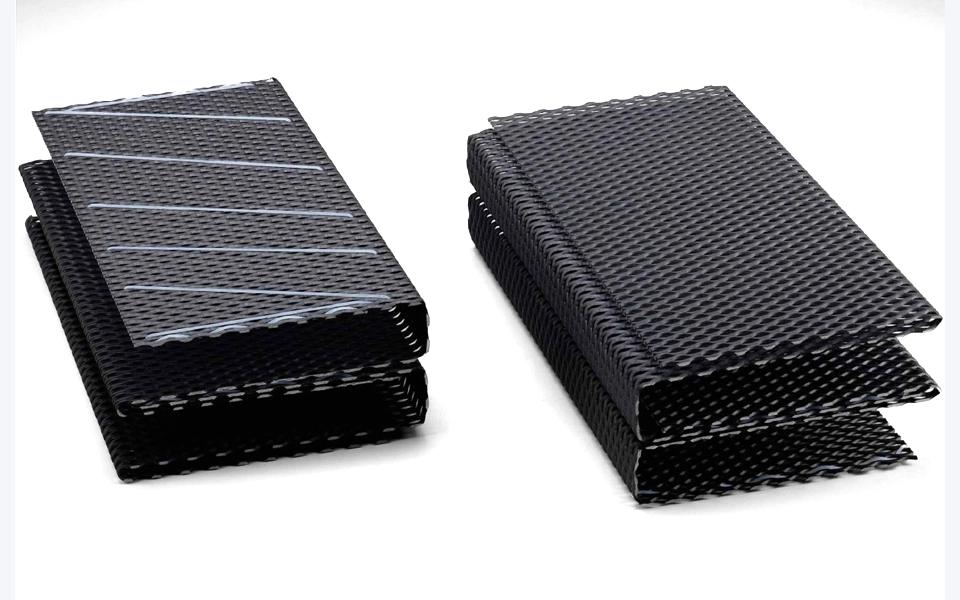

Introduction to Titanium Anode Mesh

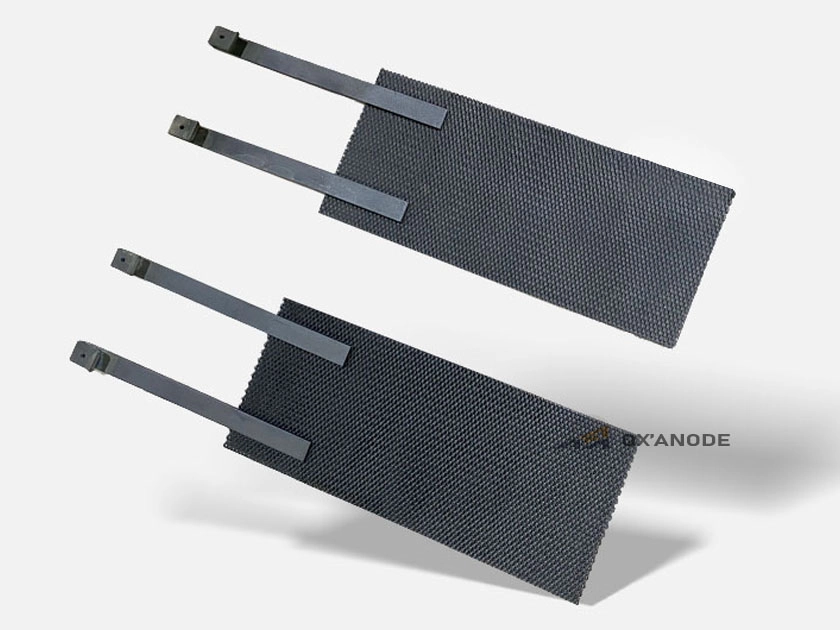

Titanium anode mesh is a critical component widely utilized in various electrochemical processes. Its unique structure consists of thin, interconnected strands of titanium, which form a network that maximizes surface area while ensuring efficient flow of the electrolyte. This design is particularly advantageous as it allows for more effective mass transfer during electrochemical reactions. The increased surface area provided by the anode mesh translates to improved reaction rates, enhancing the overall efficiency of the electrochemical system.

The choice of titanium as a material for anodes is underpinned by its exceptional properties. Titanium exhibits remarkable corrosion resistance, especially when exposed to harsh electrolytic environments. This is primarily due to the formation of a stable passive oxide layer on its surface, which protects the underlying metal from aggressive ions. As a result, titanium anodes tend to have a much longer lifespan compared to those made from other materials, making them a cost-effective choice over time. Furthermore, titanium’s outstanding durability ensures that it can withstand the mechanical stresses often encountered in industrial settings, further solidifying its role as a preferred anode material.

Electrical conductivity is another key characteristic of titanium, allowing for efficient electron transfer during electrochemical reactions. This property helps to reduce energy losses, thereby improving the overall performance of the electrochemical system. The use of titanium anode mesh not only boosts the kinetics of the reactions but also supports optimal conductivity, directly impacting the output and effectiveness of the electrochemical processes in which they are employed.

In essence, titanium anode mesh represents a significant advancement in electrochemical applications, contributing to durability, efficiency, and longevity. Its merits are well recognized across various industries, including wastewater treatment, electroplating, and battery technology. Understanding the integral role of titanium anode mesh in these processes lays the foundation for appreciating its continued relevance and application in modern electrochemistry.

Importance of Coating in Anode Mesh

The utilization of coated titanium anode mesh plays a pivotal role in enhancing the performance of electrochemical systems. Coating these anodes significantly improves their surface properties, primarily by bolstering conductivity and chemical resistance. The efficiency of electrochemical reactions is closely associated with the nature of the anode material. Uncoated titanium can exhibit limitations under certain operational conditions, such as high temperatures or aggressive chemical environments. Thus, applying a coating can mitigate these challenges and improve the stability and reliability of the anode over time.

There are various types of coatings that can be applied to titanium anode meshes, each offering unique benefits. For instance, polymer coatings provide an excellent barrier against corrosion, while metal oxide coatings can enhance electron transfer rates. The selection of the coating depends on the specific application and the environmental conditions the anode will encounter. By tailoring the coating material to the needs of the electrochemical process, it is possible to improve the anode’s efficacy significantly, translating to longer operational lifespans and reduced maintenance costs.

Moreover, advanced coatings can also facilitate better adhesion of the anode to other materials, leading to a more effective overall assembly in electrochemical cells. Understanding the characteristics and requirements of each type of coating allows engineers to optimize the anode mesh for specific tasks, be it in wastewater treatment, energy conversion, or industrial production processes. The integration of coated titanium anode meshes not only enhances operational performance but also contributes to the overall sustainability of electrochemical technologies. Coatings represent a vital advancement in materials science, and their application to titanium anodes is a testament to the ongoing evolution in the field.

Applications in Water Treatment

The utilization of coated titanium anode mesh in water treatment processes represents a significant advancement in electrochemical technology. Its applications span various methods, including electrocoagulation and electrooxidation, both of which play crucial roles in enhancing water purification and wastewater treatment outcomes. The highly conductive properties and corrosion resistance of titanium make it an ideal choice for anode materials in these processes.

Electrocoagulation is one of the prominent applications of coated titanium anode mesh, wherein electrical current causes coagulation of contaminants suspended in water. The anode facilitates the oxidation of metal ions, which then combine with impurities to form larger particles that can be easily removed from the water. This method has been proven effective in treating a wide range of pollutants such as heavy metals, oils, and organic contaminants. Numerous studies have demonstrated the successful deployment of titanium-coated anodes in municipal wastewater treatment facilities, leading to significant reductions in chemical oxygen demand (COD) and total suspended solids (TSS).

In addition to electrocoagulation, the electrooxidation process employs coated titanium anode mesh to aid in the degradation of organic pollutants, particularly in industrial effluent. By generating reactive oxygen species and active chlorine during the electrochemical reactions, these titanium anodes facilitate the breakdown of complex organic compounds. Case studies have highlighted the successful application of this technology in textile and pharmaceutical industries, where the removal of dye and other hazardous substances is critical.

Furthermore, the versatility of coated titanium anode mesh allows for its integration into advanced oxidation processes (AOPs), further enhancing its utility in water treatment. The combination of different electrochemical processes, aided by titanium anodes, showcases effective approaches to achieving cleaner and safer water sources. Overall, the applications of coated titanium anode mesh in water treatment illustrate the potential of innovative electrochemical techniques to address some of the pressing challenges in environmental sustainability.

Role in Energy Production

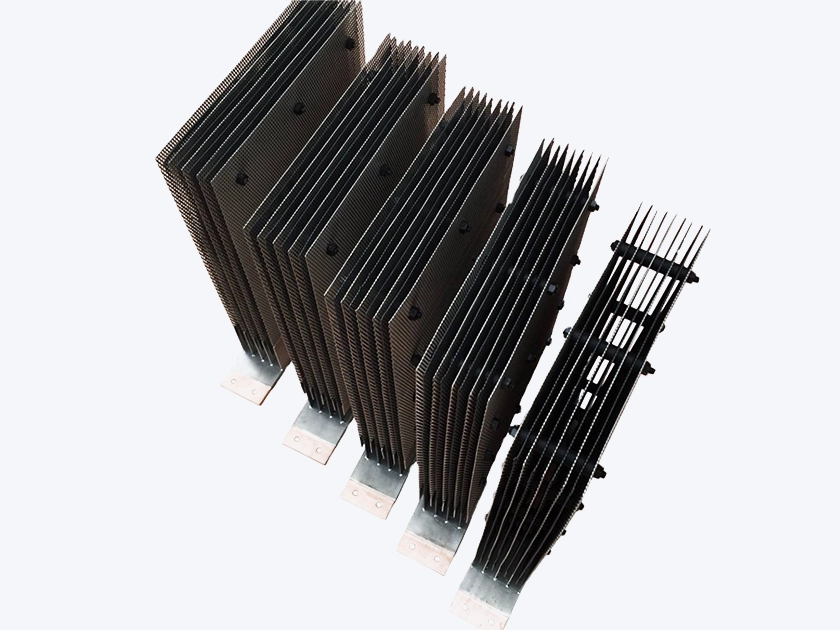

Coated titanium anode mesh plays a pivotal role in energy production, significantly enhancing the efficiency of electrochemical devices such as fuel cells and electrolyzers. These anodes are constructed from titanium, a material known for its excellent corrosion resistance and mechanical strength. By applying a specialized coating, the surface properties of the titanium mesh are improved, resulting in increased surface area and enhanced electrocatalytic activity. This enhancement is vital for optimizing the performance of electrochemical processes.

In fuel cells, coated titanium anode mesh facilitates the efficient conversion of chemical energy into electrical energy. The anode serves as a site for the oxidation of the fuel, usually hydrogen, facilitating the release of electrons that subsequently travel through an external circuit to generate electricity. The advanced coatings on these anodes improve the overall kinetics of the reactions occurring at the anode surface, reducing energy losses and thereby enhancing the cell’s power output. This leads to a more efficient energy production cycle, crucial for renewable energy solutions.

Similarly, in electrolyzers, which are used to produce hydrogen from water via electrolysis, coated titanium anode mesh ensures improved efficiency by minimizing overpotential losses. The coating on the titanium anode allows for better gas diffusion and reaction rates, promoting hydrogen generation using renewable energy sources like solar or wind power. By adopting coated titanium anodes in these devices, energy conversion processes become more effective, enabling greater exploitation of sustainably sourced energy.

In essence, the application of coated titanium anode mesh significantly contributes to increasing energy efficiency across various electrochemical systems. Its unique properties not only enhance the performance of fuel cells and electrolyzers but also facilitate the transition towards more sustainable energy production solutions.

Benefits of Using Coated Titanium Anode Mesh

The integration of coated titanium anode mesh into electrochemical processes presents a multitude of significant benefits that enhance both operational efficiency and long-term viability. One of the foremost advantages is improved durability. Coated titanium is inherently resistant to corrosion, which extends the lifespan of the anode mesh and minimizes the degradation typically associated with other materials. This characteristic is crucial in harsh chemical environments, ensuring that the anode remains functional over extended periods without requiring frequent replacements.

In addition to durability, the use of coated titanium anodes leads to increased operational efficiency. The unique properties of titanium allow for effective current distribution across the mesh surface, enhancing electrochemical reactions. This aspect is particularly notable in applications such as electrolysis and wastewater treatment, where consistent performance is vital. The electrochemical performance is further enhanced by the coatings applied to the titanium substrate, which can be tailored to optimize reaction kinetics based on specific application requirements.

Cost-effectiveness is another key benefit to consider. While the initial investment in coated titanium anode mesh may be higher than traditional materials, the long-term savings associated with reduced maintenance costs and the elimination of frequent replacements can lead to a net positive economic impact. Moreover, the efficiency gains result in lower energy consumption, translating into additional cost reductions over time.

Moreover, using coated titanium anode mesh supports environmental sustainability. Its prolonged lifespan and efficiency lead to less waste generation, aligning with modern sustainability initiatives. In conclusion, the collective benefits of improved durability, increased operational efficiency, and reduced maintenance costs make coated titanium anode mesh a highly advantageous choice for various electrochemical applications.

Challenges and Limitations

Coated titanium anode mesh has garnered attention for its applications in electrochemical processes, but it is not without its challenges and limitations. One significant issue is the degradation of the coating over time. Coatings are typically required to endure harsh operational environments, which can lead to wear and tear that ultimately affects their performance. For instance, factors such as corrosion, mechanical stress, and temperature fluctuations can contribute to this degradation, compromising the integrity of the anode and decreasing its efficiency. Hence, ensuring the longevity of the coating materials emerges as a crucial factor in the successful application of titanium anode mesh.

Another challenge relates to cost considerations. The manufacturing process of coated titanium anode mesh can be relatively expensive, often due to the advanced materials and technologies involved in the coating application. While the initial investment may be justified by the benefits of improved electrochemical performance, the overall economic viability must be assessed, especially for large-scale operations. Companies may face difficulties balancing the cost of these coated materials with the level of performance and durability required for their specific applications, which may lead them to reconsider adopting this technology.

Furthermore, compatibility with various electrolytes poses another limitation. Not all coated titanium anode meshes are universally compatible with different types of electrolytes. Certain coatings might perform well with specific electrolytes but become less effective or even unsuitable when interacting with others. This variability necessitates thorough testing and evaluation to ascertain which combinations produce optimal results in electrochemical processes. Addressing these issues is pivotal for advancing the application of coated titanium anode mesh, presenting opportunities for innovation and improvement in this field.

Future Trends in Coated Titanium Anode Mesh Technology

The coated titanium anode mesh technology is experiencing a transformative phase, driven by innovations that promise to enhance its performance and expand its applications. One of the most notable trends is the development of advanced coating materials that improve the overall efficiency of electrochemical processes. Researchers are exploring various composite and organic-inorganic hybrid coatings that not only increase durability but also enhance electrochemical stability. These materials can withstand higher operational stresses and exhibit superior catalytic properties, making them essential for both industrial and environmental applications.

Furthermore, the potential applications of coated titanium anode mesh are broadening significantly as new industries recognize the benefits of this technology. For instance, sectors such as renewable energy, wastewater treatment, and even food processing are beginning to harness the advantages of coated titanium anode mesh. In renewable energy, these anodes can significantly boost the efficiency of electrolysis processes, which are fundamental for hydrogen production and energy storage systems. Additionally, their application in wastewater treatment allows for more efficient electrochemical oxidation of pollutants, contributing to enhanced environmental sustainability.

Ongoing research and development efforts are integral to these advancements. Focused studies are being conducted to optimize the mesh geometry and surface characteristics to maximize the performance of coated titanium anodes in various operational contexts. Moreover, there is a growing emphasis on sustainability, prompting researchers to investigate biodegradable or eco-friendly alternatives to traditional coating materials. The environmental impact of producing and disposing of these anodes is thus becoming a focal point of innovation, leading to systems that not only perform well but also adhere to stringent environmental regulations.

In conclusion, the future of coated titanium anode mesh technology looks promising, with advancements in materials and processes paving the way for its application across diverse industries. The drive towards sustainability and performance optimization will continue to shape the evolution of this technology in the years to come.

Case Studies of Successful Implementations

Coated titanium anode mesh has demonstrated its efficacy across several industries, most notably in wastewater treatment, renewable energy, and various industrial electrochemical processes. These case studies illustrate the versatility and effectiveness of this advanced technology in addressing unique challenges faced by different sectors.

One exemplary case study can be found in the field of wastewater treatment. A municipal wastewater treatment plant implemented coated titanium anode mesh for an enhanced electrocoagulation system. The facility aimed to eliminate persistent contaminants and reduce chemical usage. Through the integration of coated titanium anodes, the plant achieved a significant reduction in pollutant levels while also enhancing the overall efficiency of the treatment process. This successful application not only improved water quality but also resulted in operational cost savings.

In the renewable energy sector, a notable instance involved the use of coated titanium anode mesh in the electrolysis process for hydrogen production. A research institution tested this technology to improve hydrogen generation efficiency, essential for sustainable energy solutions. The incorporation of coated titanium anodes allowed for increased current efficiency and reduced energy input compared to traditional setups. This advancement presents a promising approach for future hydrogen production methodologies, aligning with global energy transition goals.

Furthermore, coated titanium anode mesh has proved beneficial in industrial electrochemical applications such as metal plating. A manufacturing facility utilized this technology to enhance their plating line, which faced issues related to anode life and deposition quality. The adoption of coated titanium anode mesh resulted in improved anode durability and more uniform coating, leading to reduced maintenance costs and enhanced product quality. These examples showcase the successful implementation of coated titanium anodes across diverse applications, underlining their transformative potential within various sectors.

Conclusion and Recommendations

In conclusion, the application of coated titanium anode meshes in electrochemical processes represents a significant advancement in various industrial sectors. Throughout this article, we have examined the unique properties of coated titanium anodes, such as their enhanced conductivity, corrosion resistance, and overall durability. These characteristics not only optimize electrochemical reactions but also extend the lifespan of the electrodes, thereby improving efficiency and reducing operational costs.

For industries considering the adoption of coated titanium anode meshes, we recommend several best practices to ensure successful implementation. First, organizations should conduct a thorough assessment of their specific electrochemical processes to determine the suitability of titanium anodes. Understanding the chemical environments and operational conditions will aid in selecting the optimal coating material and configuration. Additionally, engaging in partnerships with reputable manufacturers can provide invaluable insights and technical support.

It is also advisable to invest in training programs for personnel who will be working with these advanced materials. A well-informed workforce can significantly contribute to leveraging the advantages provided by coated titanium anode meshes, enhancing overall safety and operational efficiency. Regular maintenance checks and performance evaluations should be conducted to monitor the condition of the anodes, ensuring they perform optimally throughout their lifecycle.

Furthermore, we encourage continued research and exploration in this promising area of technology. The potential applications of coated titanium anode meshes extend beyond the conventional uses discussed in this article, hinting at new opportunities for innovation and improvement within the electrochemical field. By fostering a collaborative approach among researchers, manufacturers, and end-users, the industry can unlock further advancements that may contribute to more sustainable and efficient electrochemical processes.