Lead dioxide titanium anode

The Innovator of Hydrometallurgy

Explore how the new generation of anode materials can improve the extraction efficiency of non-ferrous metals, reduce energy consumption, and promote the innovation of hydrometallurgical technology.

Research Abstract

Focus on the application of Lead dioxide titanium anode in hydrometallurgy. This anode material can significantly improve current efficiency, reduce energy consumption, and extend service life, providing an efficient and environmentally friendly solution for non-ferrous metal extraction.

With the acceleration of the global industrialization process, the demand for non-ferrous metals has been continuously rising. Hydrometallurgy, as an important metal extraction method, plays a pivotal role in the modern metallurgical industry.

Traditional anode materials, such as lead-based alloy anodes, have problems such as high oxygen evolution overpotential, high energy consumption, easy corrosion, and short lifespan, resulting in an increase in production costs and a decline in product quality.

Limitations of traditional anode materials

- The oxygen evolution overpotential is high and the energy consumption is large.

- High density, low strength, easy to bend and creep.

- The surface passivation film is loose and prone to corrosion.

- Cause lead contamination of cathode products.

Energy consumption reduction

The oxygen evolution overpotential is reduced by 0.2 - 0.5V, and the power consumption is decreased by 20 - 30%.

Life extension

The service life is 3 to 5 times that of traditional lead - based anodes, reducing the replacement frequency.

Overview of Lead dioxide titanium anode

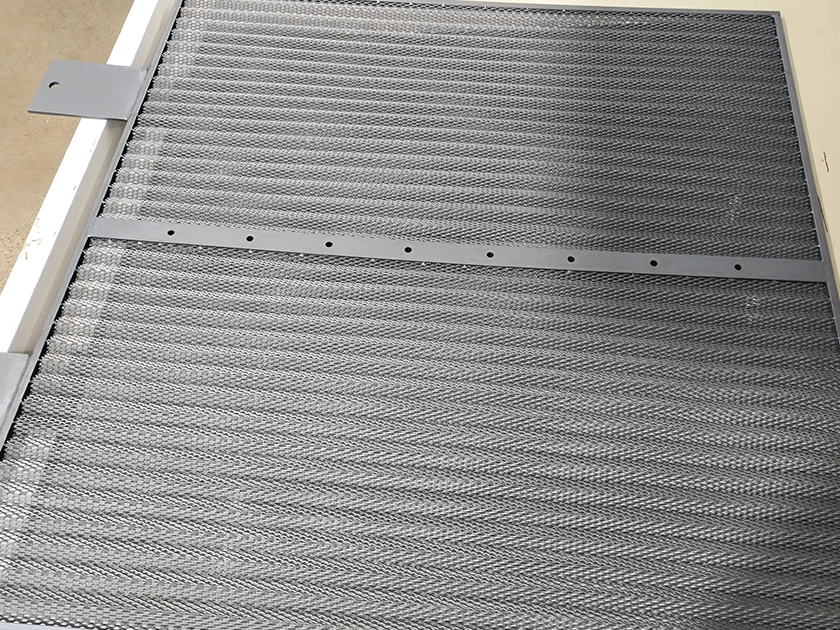

The lead dioxide titanium anode is a composite electrode material with titanium as the substrate and a lead dioxide layer plated on the surface. It has excellent electrochemical properties and stability.

Basic structure and working principle

The lead dioxide - titanium anode consists of a titanium mesh substrate and a lead dioxide active layer. The titanium substrate provides mechanical strength and electrical conductivity, and the lead dioxide active layer is directly involved in the electrochemical reaction.

Structural composition

Titanium substrate (mechanical support) + lead dioxide active layer (electrocatalytic reaction). The β-PbO₂ crystal form is more commonly used due to its high electrical conductivity and catalytic activity.

Working principle

An oxidation reaction occurs on the anode surface. The lead dioxide coating reduces the oxygen evolution overpotential, promotes the discharge of OH⁻ ions to generate oxygen, and electrons are conducted through the titanium substrate.

Features and preparation processes

Lead dioxide titanium anode has unique physical, chemical and electrochemical properties, and its preparation process directly affects the performance and service life of the anode.

Physical Chemistry and Electrochemical Properties

Physical and chemical properties

- β-PbO₂crystal form: tetragonal system, rutile structure, high electrical conductivity

- Titanium matrix: density is 4.51g/cm³, high strength, corrosion-resistant

- Lead dioxide coating: density 9.375g/cm³, insoluble in water and ethanol

- High stability: The titanium substrate has a strong bonding force with the coating, resistant to peeling.

Electrochemical properties

- High oxygen evolution potential: ≥1.7V (vs. SHE), reducing side reactions.

- High current efficiency: usually >90%, with a 5 - 10% increase in zinc electrowinning.

- Strong electrocatalytic activity: The surface provides abundant active sites to promote the reaction.

- Low oxygen evolution overpotential: 0.2 - 0.5V lower than traditional anodes, reducing energy consumption.

Preparation processes and technologies

Traditional preparation method - electroplating method

Electroplating is a common method for preparing lead dioxide-titanium anodes, which includes three main steps: pretreatment of the titanium substrate, preparation of the electroplating solution, and electrodeposition.

- Preprocessing:Remove oil with alkaline solution, remove rust with acid solution, and roughen the surface.

- Electroplating solution:Lead nitrate solution, with additives such as nitric acid and boric acid.

- Electrodeposition:Control the current density, temperature, and time to form a lead dioxide coating.

Technological innovation points

The grain size of the lead dioxide-titanium anode prepared by pulse electrodeposition technology is significantly reduced, the coating is denser, the electrocatalytic activity is increased by 20 - 30%, the bonding force is stronger, and the service life is effectively extended.

Mechanism of action

The action mechanism of lead dioxide titanium anode in hydrometallurgy involves complex electrochemical reaction processes, which directly affect the metal extraction efficiency and product quality.

Electrochemical reaction process

During the electrolysis process, an oxidation reaction occurs on the surface of the Lead dioxide titanium anode, reducing the oxygen evolution overpotential and promoting the discharge of OH⁻ ions to generate oxygen.

Anodic reaction:

2H₂O → O₂ + 4H⁺ + 4e⁻

(The oxygen evolution overpotential is 0.2 - 0.5V lower than that of the traditional anode.)

Impact on the extraction efficiency of metals

High oxygen evolution potential inhibits side reactions and improves current efficiency; the surface structure promotes the mass transfer of metal ions and accelerates the reaction rate.

Effect on reaction selectivity

By adjusting the electrode potential and surface properties, the Lead dioxide titanium anode can selectively dissolve the target metal and reduce impurity interference.

Case: Separation of Copper and Iron

By controlling the potential, copper ions are preferentially dissolved while iron ions remain in the residue, increasing the selectivity of copper extraction by 20 - 25%.

Application cases

Lead dioxide titanium anodes have been widely used in the field of non-ferrous metal electrowinning, significantly improving production efficiency and product quality.

Copper electrowinning

In the copper electrowinning process, the lead dioxide-titanium anode increases the current efficiency to over 95%, reduces the energy consumption by 25%, and raises the purity of cathode copper to 99.95%.

Advantages

High current efficiency, low energy consumption.

Zinc electrowinning

In zinc electrowinning, the use of lead dioxide-titanium anodes increases the current efficiency by 8 - 10% and extends the anode life to 3 - 5 years, significantly reducing the production cost.

Advantages

Long lifespan, high selectivity.

Nickel-cobalt electrowinning

In nickel-cobalt electrowinning, the lead dioxide-titanium anode effectively inhibits the oxygen evolution side reaction, improves the product purity, and the cobalt recovery rate reaches over 98%.

Advantages

High selectivity, low pollution.

In the electrolysis process of hydrometallurgy, the lead dioxide titanium anode is connected to the positive pole of the power supply. As the anode, it undergoes an oxidation reaction, while the cathode is connected to the negative pole of the power supply and undergoes a reduction reaction. Taking the common metal electrowinning process as an example, at the anode, the main reaction is the oxygen evolution reaction of water oxidation. In an acidic solution, oxidation reactions of other anions may also occur, but in most hydrometallurgical systems, the oxygen evolution reaction of water oxidation is the main anodic reaction. The lead dioxide titanium anode plays a key role in this electrochemical reaction process. The lead dioxide coating on its surface has good electrocatalytic activity, which can reduce the overpotential of the oxygen evolution reaction. The oxygen evolution overpotential refers to the difference between the potential at which the oxygen evolution reaction actually occurs and the theoretical oxygen evolution potential during the electrolysis process. A lower oxygen evolution overpotential means that at the same current density, a lower voltage needs to be applied, thus reducing the power consumption. Research shows that the oxygen evolution overpotential of the lead dioxide titanium anode is 0.2 – 0.5V lower than that of the traditional lead-based alloy anode, which can significantly reduce energy consumption during the electrowinning process. The crystal structure and surface properties of lead dioxide provide abundant active sites for the oxygen evolution reaction, promoting the progress of the reaction. Lattice defects and surface hydroxyl groups in the lead dioxide coating can adsorb and activate OH- ions, making it easier for them to lose electrons and undergo an oxidation reaction. At the cathode, metal ions gain electrons and are reduced to metallic substances and precipitate. For the copper electrowinning process, the good electrical conductivity of the lead dioxide titanium anode ensures that electrons can be smoothly conducted from the power supply to the electrolyte, providing sufficient electrons for the reduction reaction at the cathode. At the same time, the stability of the anode can ensure a uniform distribution of current density during the electrolysis process, which is conducive to improving the deposition quality of the cathode metal. If the anode performance is unstable, it may lead to an uneven distribution of current density, resulting in uneven deposition of the cathode metal, problems such as dendritic crystallization, and affecting the product quality.