Titanium anode

Innovate the horizontal copper plating process for PCB

Adopting the advanced iridium mixed metal oxide coating technology, it significantly improves the electroplating efficiency, reduces energy consumption, and provides a sustainable environmental solution for PCB manufacturing.

Horizontal copper plating technology

Break through the limitations of traditional electroplating processes and provide better solutions for high – demand PCB manufacturing.

In the early stages of PCB manufacturing, vertical electroplating became the mainstream method for copper plating due to its simple equipment structure and mature operating process. The PCB is vertically suspended in the electroplating tank, and the anode usually uses a soluble copper anode, such as copper balls or copper plates. During the electroplating process, the anode copper gradually dissolves into the plating solution to replenish the copper ions in the solution. This method performs well when dealing with PCBs of conventional hole diameters and board thicknesses and can meet certain production requirements.

However, with the continuous development of electronic devices towards miniaturization and high performance, the design of PCBs has become increasingly complex. The emergence of high aspect ratio vias (i.e., the ratio of hole depth to hole diameter is greater than 5:1 or even higher) and deep blind vias (blind holes with a relatively deep depth) poses severe challenges to the electroplating process. In vertical electroplating, due to the influence of gravity and solution convection, the flow of the plating solution inside the holes is non-uniform. The renewal of the plating solution at the bottom of the hole is relatively difficult, resulting in an insufficient supply of copper ions, while near the hole opening, due to the concentrated current distribution, the copper deposition rate is too fast. This causes an uneven distribution of the copper layer thickness inside the hole, and it is easy to 出现 the “dog bone” – shaped phenomenon where the copper layer thickness on the hole wall is insufficient and the copper layer at the hole opening is too thick, which seriously affects the electrical performance and reliability of the PCB. A large number of multi – layer boards are scrapped as a result, causing huge economic losses.

To solve these problems, the horizontal copper plating technology came into being. It abandons the traditional vertical hanging method, places the PCB horizontally in the electroplating equipment, and makes it move smoothly in the plating solution through a specially designed conveying system. Coupled with a precisely controlled liquid spraying and stirring system, it provides a new idea for solving the electroplating challenges of high aspect ratio through holes and deep blind holes.

Principle of horizontal copper plating

The basic principles of horizontal copper plating and vertical electroplating are the same. However, through a specially designed conveying and liquid spraying system, the electroplating challenges of high aspect ratio through-holes and deep blind holes are solved.

Essentially, the basic principles of horizontal copper plating and vertical electroplating are the same, both following the basic laws of electrochemical deposition. During the electroplating process, when the positive and negative electrodes in the electroplating tank are connected to a DC power supply, a complete electrolysis circuit is formed. Main salts such as copper sulfate (CuSO4) in the plating solution are ionized, generating copper ions (Cu 2+) and sulfate ions (SO42−). Under the action of the electric field force, the positively charged copper ions migrate towards the cathode (i.e., the PCB to be plated), while the negatively charged sulfate ions move towards the anode.

Advantages of horizontal copper plating

High current density

Speed up the copper plating speed and improve production efficiency

Excellent dispersion ability

Ensure uniform copper layer within complex hole structures

Thin plate adaptability

Avoid thin plate deformation and ensure the quality of the coating.

Automated production

Reduce human errors and improve production stability.

Compared with traditional vertical electroplating, the horizontal copper plating process exhibits many remarkable characteristics and advantages. In terms of current density, horizontal copper plating has significant room for improvement. Since the PCB is placed horizontally, the distance between the anode and the cathode can be greatly shortened, thereby reducing the resistance during the electroplating process. According to Ohm’s law, under the same voltage conditions, the reduction in resistance enables a significant increase in the passing current density. This means that more copper ions can be reduced and deposited on the cathode surface per unit time, greatly accelerating the copper plating speed and improving production efficiency. In contrast, vertical electroplating is limited by the electrode spacing and solution resistance, making it more difficult to increase the current density and restricting the further improvement of production efficiency.

Titanium anode for horizontal copper plating on PCB

In the PCB horizontal copper plating system, the titanium anode, as an insoluble anode, undertakes the crucial oxidation reaction and provides stable support for high – quality copper plating.

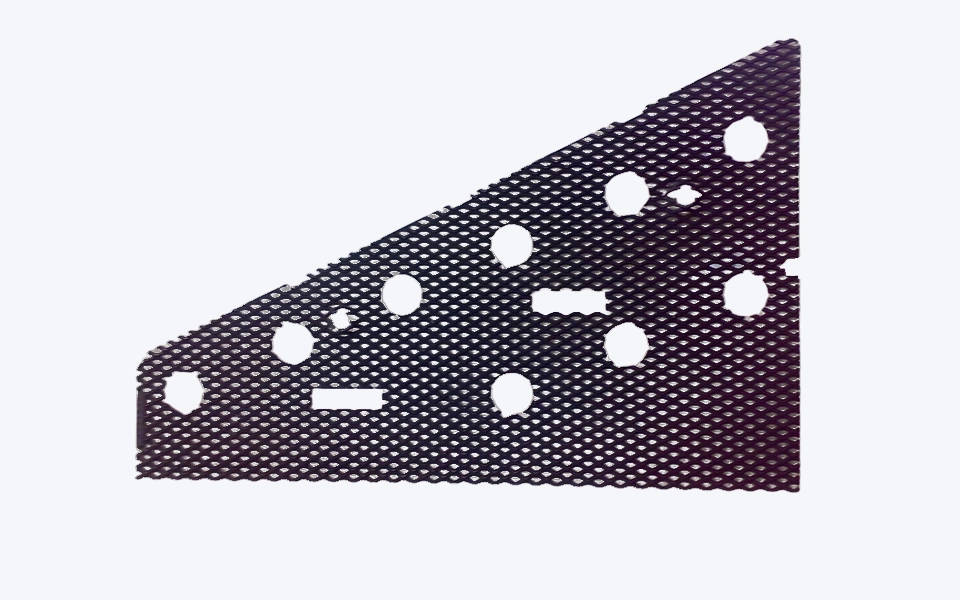

Titanium anode, whose full name is titanium-based metal oxide coated electrode (MMO), is also known as an insoluble anode and plays a crucial role in the PCB horizontal copper plating process. Its basic structure is like a meticulously constructed building. The substrate made of industrial pure titanium (Gr1/Gr2) is the solid foundation of this building. Titanium, this amazing metal, has a density of only about 4.5g/cm³, yet it has an excellent strength-to-weight ratio and can maintain the integrity of its structure when subjected to large external forces. Its melting point is as high as 1668℃, and it can still maintain stable physical properties in a high-temperature environment, providing a reliable guarantee for the continuous operation of the anode during the electroplating process. Industrial pure titanium has excellent corrosion resistance, enabling it to resist the erosion of various chemical substances in the complex electroplating solution environment and effectively extending the service life of the anode.

On the surface of the titanium substrate, there is a catalytic coating composed of noble metal oxides such as IrO₂. This coating is like an “intelligent protective film” of a building. IrO₂ is renowned for its high stability and excellent corrosion resistance. It can maintain the integrity of the coating during long – term electrolysis and prevent the titanium substrate from being corroded. It also has a good catalytic effect on the redox reaction of electroplating additives, helping to maintain the effective concentration of additives in the plating solution and improve the quality of the coating. These noble metal oxides are uniformly coated on the surface of the titanium substrate by a special process, the thermal decomposition method, and after high – temperature sintering treatment, they are closely combined with the titanium substrate to form a stable catalytic system.

Performance Advantages of Titanium Anodes

Titanium anode technology brings multi – aspect performance improvements to the PCB copper plating process, meeting the strict requirements of modern electronics manufacturing.

High current efficiency

environmental protection

Friendly to additives

Good corrosion resistance

Stable current distribution: During the horizontal copper plating process of PCBs, ensuring a uniform current distribution is of utmost importance. The titanium anode, with its dimensional stability, becomes the key to solving this problem. Traditional soluble copper anodes gradually dissolve during the electroplating process, causing changes in the anode’s size and shape. This change leads to fluctuations in the resistance between electrodes, and consequently, an uneven current distribution. In contrast, the titanium anode, as an insoluble anode, maintains almost constant dimensions throughout the electroplating process. Its stable geometric shape results in a more uniform electric field distribution, allowing the current to pass through the plating solution uniformly and reach the PCB surface. This effectively avoids the problem of uneven copper deposition in holes caused by current concentration, such as the common “dog-bone” phenomenon. By precisely controlling the current distribution, the titanium anode enables the uniform reduction and deposition of copper ions in high-aspect-ratio through-holes and deep blind holes, ensuring that the copper plating layer has a consistent thickness at all parts of the hole wall, greatly improving the electrical performance and reliability of the PCB.

Boosting Additive Regeneration: Electroplating additives play a crucial role in regulating the coating structure and improving the coating properties in horizontal copper plating. However, during the electroplating process, the additives continuously undergo redox reactions, and their active components are gradually consumed. The noble metal oxide coating on the surface of the titanium anode has excellent catalytic activity and can strongly promote the regeneration of electroplating additives. Taking common leveling agents and brighteners as examples, after they undergo oxidation reactions on the cathode surface, they lose their original activity. The titanium anode can catalyze these oxidation products to be re-reduced into active additive molecules, enabling them to continue to function. This catalytic regeneration not only reduces the amount of additive replenishment and lowers the production cost but also maintains the stability of the additive concentration in the plating solution, making the electroplating process more stable and conducive to obtaining high-quality and consistent copper coatings.

In the PCB horizontal copper plating system, the electrolyte is usually acidic, and its main components include an aqueous solution of copper sulfate (CuSO₄) and sulfuric acid (H₂SO₄). When an electric current passes through the electrolytic cell, the PCB board acts as the cathode, where the reduction reaction of copper ions (Cu²⁺) occurs, and a copper layer is deposited on the surface of the PCB. The titanium anode, as an insoluble anode, undertakes the responsibility of the oxidation reaction. In an acidic environment, the oxygen evolution reaction (OER) mainly occurs on the anode, and its reaction equation is: 2H₂O → O₂ + 4H⁺ + 4e⁻.

The anode is not simply a metal electrode but a coated electrode. Its substrate is made of industrial pure titanium (Gr1/Gr2). This material has good electrical conductivity, ductility, and corrosion resistance in acidic solutions, and its cost is relatively reasonable, providing a stable support structure for the anode. On the surface of the titanium substrate, a layer of noble metal oxide coating with high electrocatalytic activity, iridium mixed metal oxide (Ir MMO), is coated. This coating can significantly reduce the overpotential of the oxygen evolution reaction, promote the efficient progress of the reaction, enable a stable anodic reaction to be achieved at a lower cell voltage, and thus improve the energy utilization efficiency of the electroplating process.