Titanium anode: An In depth Analysis from Principles to Diversified Applications

Overview

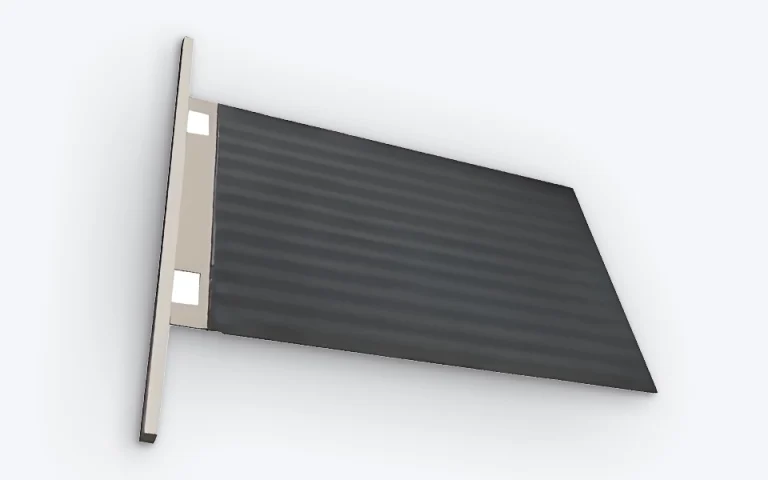

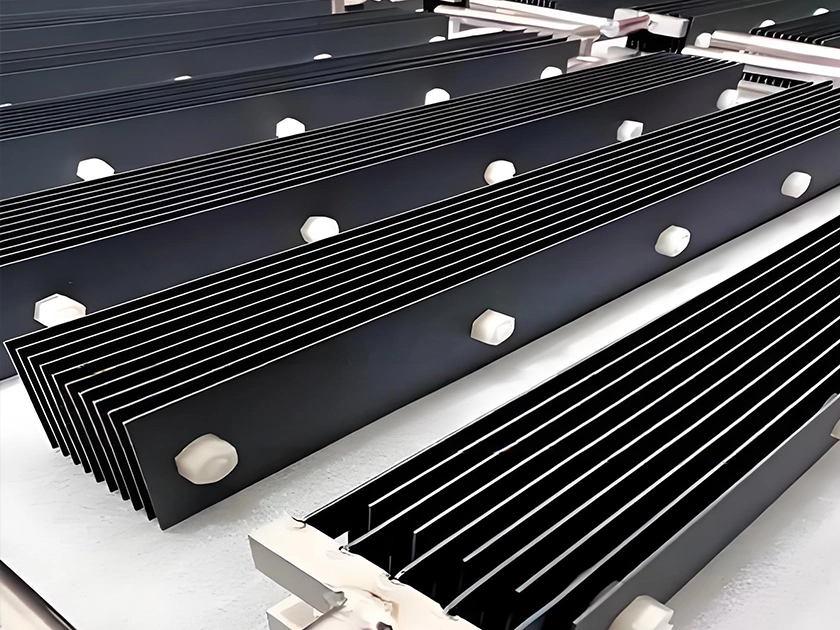

Titanium anode

Titanium anode is an inert anode widely used in the modern electrochemical industry, known for its excellent catalytic performance and corrosion resistance.

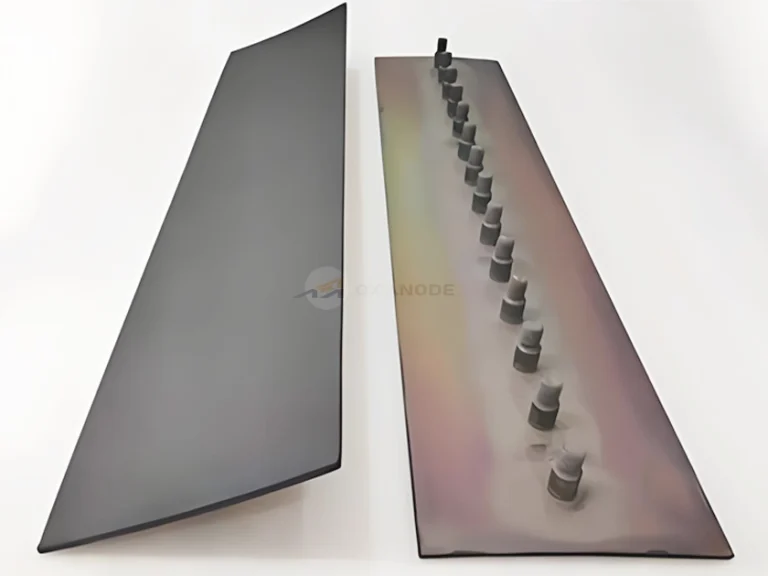

Titanium anode, whose core structure is based on a titanium substrate with a surface coating of mixed metal oxides. Common mixed metal oxides include the oxides of ruthenium (Ru), iridium (Ir), platinum (Pt), etc. These mixed metal oxides have unique crystal structures and electronic properties, which are the key factors determining the anode performance. For example, ruthenium-based oxide coatings have good catalytic activity for the chlorine evolution reaction, which can reduce the overpotential of chlorine evolution and enable the reaction to proceed efficiently at a lower voltage. This is because the crystal structure of ruthenium oxide can provide abundant active sites, promoting the discharge reaction of chloride ions and accelerating the generation of chlorine gas. In the ion-exchange membrane electrolyzer of the chlor-alkali industry, ruthenium oxide catalyzes the chloride ions in saturated brine to lose electrons and generate chlorine gas, greatly improving the electrolysis efficiency.

Iridium based oxide coatings perform outstandingly in the oxygen evolution reaction and are commonly used in electrochemical reaction systems that require oxygen evolution at the anode. Iridium oxide coatings have high stability and catalytic activity, which can effectively reduce the oxygen evolution overpotential and increase the oxygen evolution reaction rate. During the process of water electrolysis to produce oxygen in an acidic medium, the iridium-based coated titanium anode can efficiently catalyze the decomposition of water molecules to generate oxygen while maintaining good stability and being resistant to corrosion.

The function of the coating is not only to provide catalytic activity, but also to enhance the stability and corrosion resistance of the anode. Although the titanium substrate itself has good corrosion resistance, it may still corrode in some specific electrochemical environments. The mixed metal oxide coating can form a dense protective film on the surface of the titanium substrate, preventing the electrolyte from coming into direct contact with the titanium substrate, thus protecting the titanium substrate from corrosion. The coating can also improve the electrical conductivity of the anode, making up for the insufficient electrical conductivity of titanium itself, ensuring uniform distribution of current on the electrode surface, and improving the efficiency and uniformity of the electrochemical reaction.

In different electrolyte systems, the electrochemical reaction processes in which the coated titanium anode participates are somewhat different. Taking the common chlor-alkali industry as an example, in the saturated brine electrolyte system, the main reaction occurring at the anode is the oxidation reaction of chloride ions to generate chlorine gas. The reaction formula is: 2Cl⁻ – 2e⁻ = Cl₂↑. On the surface of the ruthenium-iridium titanium anode, due to the catalytic effect of the coating, chloride ions can more easily lose electrons, thereby reducing the overpotential of the reaction and increasing the reaction rate. At the same time, the dimensional stability and corrosion resistance of the titanium anode ensure that during the long-term electrolysis process, the electrode can work stably and ensure that the electrolysis operation proceeds at a stable cell voltage.

In the process of electrolyzing water to produce hydrogen and oxygen, if an acidic electrolyte is used, the oxygen evolution reaction occurs at the anode. Taking sulfuric acid electrolyte as an example, the reaction formula is: 2H₂O – 4e⁻ = O₂↑ + 4H⁺. In this case, the iridium – based coated titanium anode plays a role. Its coating can effectively catalyze the decomposition of water molecules, reduce the oxygen evolution over – potential, enable the reaction to proceed at a lower voltage, and improve the efficiency of water electrolysis. In an alkaline electrolyte, although the specific form of the reaction is different, the coated titanium anode can also promote the oxidation reaction of water to produce oxygen through its catalytic activity.

In the electroplating industry, such as in the chromium plating process, an electrolyte containing hexavalent chromium is used. At this time, an oxygen evolution reaction occurs on the surface of the iridium-titanium anode. The reaction equations are: 4OH⁻ – 4e⁻ = O₂↑ + 2H₂O (in an alkaline environment) or 2H₂O – 4e⁻ = O₂↑ + 4H⁺ (in an acidic environment). The iridium oxide on the anode surface catalyzes the oxygen evolution reaction, and the electrical conductivity of the titanium substrate ensures a uniform distribution of current, enabling the chromium layer to be evenly deposited on the cathode surface and improving the quality and performance of the chromium plating layer.

Characteristics and Advantages of Titanium Anode

- High electrocatalytic activity

Titanium anode have extremely high electrocatalytic activity, which enables them to significantly reduce the reaction overpotential in electrochemical reactions, thus increasing the reaction rate. In the chlor – alkali industry, traditional graphite anodes have a relatively high overpotential during the chlorine evolution reaction, resulting in a large amount of electrical energy consumption in the electrolysis process. However, the ruthenium – iridium titanium anode has a low overpotential for chlorine, which is 140 mV lower than that of the graphite anode at 1A/cm². Data from a chlor – alkali production enterprise shows that after using the titanium anode, the power consumption per ton of caustic soda is reduced by 280 kWh compared with using the graphite anode. This is because the mixed metal oxide coating on the surface of the titanium anode provides abundant catalytic active sites, which can accelerate the discharge process of chloride ions and make the chlorine evolution reaction proceed more easily. In the field of hydrogen production by water electrolysis, the ruthenium – titanium anode can reduce the overpotential of the oxygen evolution reaction, reducing the hydrogen production energy consumption from 4.8 kWh/Nm³ to 4.2 kWh/Nm³. Calculated based on an annual hydrogen production of 1000 tons, this improvement alone can save 2 million yuan in electricity costs. This fully demonstrates the significant energy – saving effect and economic benefits brought about by the high electrocatalytic activity of titanium anode. - Good stability

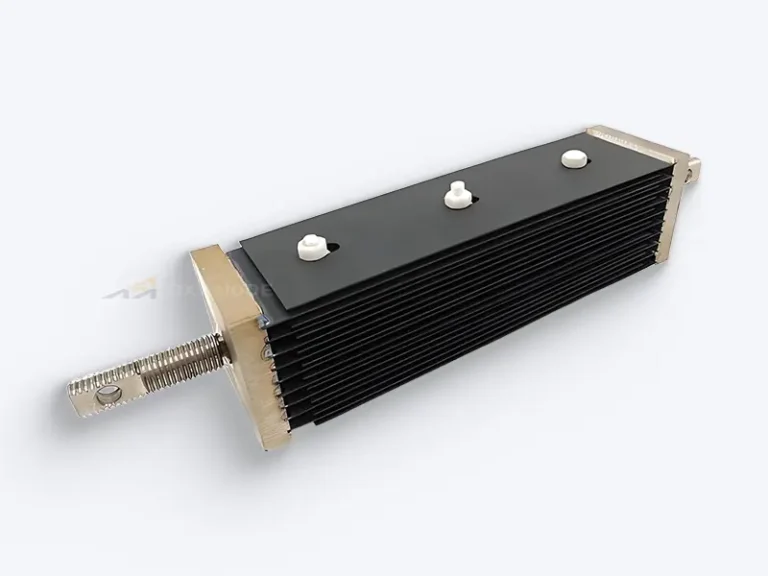

Through special process treatment, a firm bond is formed between the titanium substrate and the coating, ensuring the stability of the anode in different environments. In the ion-exchange membrane electrolyzer of the chlor-alkali industry, the anode needs to be in an environment of high temperature, high-concentration sodium chloride solution, and highly corrosive chlorine gas for a long time. The titanium substrate of the titanium anode has good corrosion resistance and can resist the erosion of chloride ions and alkaline environments. The surface mixed metal oxide coating has a stable chemical composition and crystal structure and is not prone to chemical reactions and structural changes. In a 20% sodium hydroxide solution, the titanium substrate of the titanium anode can remain stable for a long time and will not be corroded. The close combination between the coating and the substrate can also prevent the coating from falling off during the electrochemical reaction process, ensuring the stable performance of the anode. Even during a long-term electrolysis process, the coating on the anode surface can still remain intact and continue to play its catalytic and protective roles. - Long service life

In practical applications, titanium anode have a significantly longer service life compared to other anode materials. In the diaphragm method for chlor-alkali industry production, metal anodes (titanium anode) are resistant to the corrosion of chlorine and alkali, and the anode service life has reached more than 3 years, while that of graphite anodes is only 8 months. This is because of the high stability and corrosion resistance of titanium anode, enabling them to work for a long time in harsh electrochemical environments without failure. In the electrocatalytic oxidation process of sewage treatment, the service life of titanium anode is as long as more than 2 years. The coating on its surface can effectively catalyze the decomposition reaction of organic pollutants, and at the same time, it will not be corroded or poisoned by pollutants. Even when treating printing and dyeing wastewater containing various complex organic pollutants, titanium anode can still maintain good performance and continuously exert their electrocatalytic effect, while some other anode materials may quickly fail due to the adsorption and reaction of pollutants. - Strong corrosion resistance

Coated titanium anode exhibit excellent corrosion resistance in highly corrosive media. In high-concentration acid and alkali solutions, such as when treating acidic wastewater, the solution may contain strong acids like sulfuric acid and hydrochloric acid at high concentrations. The titanium substrate of the titanium anode itself has good acid resistance and can resist the erosion of acids. The mixed metal oxide coating on the surface further enhances its corrosion resistance. In the electroplating industry, the electrolyte usually contains various metal ions and highly corrosive additives. Iridium-titanium anode can operate stably in such an environment without corrosion, ensuring the smooth progress of the electroplating process. When treating wastewater containing heavy metal ions, even if the wastewater contains high concentrations of heavy metal ions such as copper, nickel, and chromium, as well as acidic media, the titanium anode can still maintain the stability of its structure and performance and will not be corroded or contaminated by heavy metal ions.

Comparison with other common anode materials

- Compared with graphite anodes

In terms of electrical conductivity, although the graphite anode has a certain degree of electrical conductivity, its resistance is relatively high compared to the titanium anode. In the chlor-alkali industry, the resistance of the graphite anode can cause a large amount of electrical energy loss during the transmission process, increasing the production cost. The titanium anode, on the other hand, has good electrical conductivity and can effectively reduce electrical energy loss. In terms of stability, the graphite anode is prone to corrosion and wear during the electrolysis process, causing changes in its size and shape and affecting the stability of electrolysis. When a chlor-alkali plant uses a graphite anode, due to the corrosion and wear of the anode, the anode needs to be replaced frequently, which not only increases the labor intensity but also affects the production efficiency. The titanium anode, however, has excellent stability. During the long-term electrolysis process, its size and shape basically remain unchanged, ensuring that the electrolysis operation can be carried out under stable conditions. In terms of lifespan, the service life of the graphite anode is relatively short. For example, in the diaphragm method for chlor-alkali production, the graphite anode can only be used for about 8 months. This is because the graphite anode is gradually corroded and consumed during the electrolysis process, resulting in a decline in its performance. The lifespan of the titanium anode can reach more than 3 years, greatly reducing the frequency of anode replacement and lowering the maintenance cost. According to the production data statistics of an enterprise, when using a graphite anode, the anode needs to be replaced 12 times a year, while after changing to a titanium anode, it only needs to be replaced once every 3 years, which greatly improves the continuity and stability of production. - Compared with lead-based anodes

Lead based anodes have a dissolution problem during the electrochemical reaction process. In some electrodeposition processes, when Cl⁻ is present in the solution, PbCl₂ is easily soluble in water, disrupting the reaction equilibrium and leading to the rapid dissolution and consumption of lead. This not only affects the service life of the lead anode but also causes an increase in the lead – ion concentration in the electrolyte, polluting the electrolyte. During the battery production process, if a lead – based anode is used, the lead ions generated by its dissolution may contaminate the battery’s electrolyte, affecting the battery’s performance and lifespan. However, coated titanium anode do not have a dissolution problem, can avoid the pollution of the electrolyte and the cathode product, and improve the purity of metal products. In the electrical industry, using titanium anode can ensure the purity and quality of the layer and avoid the pollution of the layer by lead ions. - Comparison with other metal oxide anodes

In specific application scenarios, such as in the process of acidic medium water electrolysis for oxygen production that requires high oxygen evolution catalytic activity, compared with some other metal oxide anodes, the coated titanium anode has unique advantages. Although some other metal oxide anodes also have certain oxygen evolution catalytic activity, they may be inferior to the coated titanium anode in terms of stability and corrosion resistance. Under acidic conditions, these anodes may undergo corrosion or structural changes, leading to a decline in their performance. The iridium-based coated titanium anode can maintain good stability and catalytic activity in an acidic medium, ensuring the efficient and stable progress of the water electrolysis oxygen production process. In the electrocatalytic oxidation process of sewage treatment, the anode is required to have both good catalytic activity and corrosion resistance to cope with the complex components of sewage. The mixed metal oxide coating of the coated titanium anode can effectively catalyze the generation of hydroxyl radicals to decompose organic pollutants in the sewage. At the same time, its good corrosion resistance enables it to work stably in the sewage environment for a long time, while some other metal oxide anodes may not meet these requirements.

MMO titanium anode applications

Applications in the field of sewage treatment

Mixed metal oxide coated titanium anode play a crucial role in multiple industrial fields.

- Generation and Effects of Hydroxyl Radical

Hydroxyl radicals have extremely strong oxidation ability, with a redox potential as high as 2.8V, second only to fluorine gas. This enables them to react non – selectively with various organic pollutants in sewage. When treating sewage containing phenolic compounds, hydroxyl radicals can rapidly attack the benzene ring structure of phenolic molecules, triggering a series of oxidation reactions such as hydroxylation and ring – opening. In the specific reaction process, hydroxyl radicals first undergo an addition reaction with phenolic molecules to form phenolic hydroxyl radical intermediates. Then, the intermediates are further oxidized, and the benzene ring undergoes a ring – opening reaction to generate small – molecule organic acids such as formic acid and acetic acid. These small – molecule organic acids are ultimately completely mineralized into carbon dioxide and water. When treating organic dyes in printing and dyeing wastewater, hydroxyl radicals can destroy the chromophoric groups of dye molecules, causing the dye molecules to lose their color and decomposing them into harmless small – molecule substances. - Removal mechanisms for different pollutants

For heavy metal ions, the coated titanium anode mainly achieves their removal through electrochemical reactions. During the electrocatalytic oxidation process, heavy metal ions undergo a reduction reaction at the cathode and are reduced to metallic elements or ions in lower valence states, thus precipitating from the sewage. Taking wastewater containing copper ions (Cu₂+) as an example, on the surface of the cathode, Cu₂+ gains electrons and is reduced to metallic copper. The reaction formula is: Cu₂+ + 2e- = Cu. In the actual treatment process, when an electric current passes through the wastewater, copper ions migrate towards the cathode and gain electrons on the cathode surface to undergo a reduction reaction. The generated metallic copper deposits on the cathode surface, thus achieving the removal of copper ions. For some heavy metal ions with variable valence states, such as chromium (Cr), under acidic conditions, Cr6+ has strong oxidizing properties and is highly harmful to the environment. Through electrocatalytic oxidation, Cr6+ can gain electrons on the cathode surface and be reduced to Cr3+ with lower toxicity. The reaction formula is: Cr₂O72- + 14H+ + 6e- = 2Cr3+ + 7H₂O. Subsequently, Cr3+ will form chromium hydroxide precipitate under alkaline conditions and be removed from the wastewater.

For organic substances, in addition to the oxidation by hydroxyl radicals, there are two mechanisms of direct oxidation and indirect oxidation. Direct oxidation refers to the direct loss of electrons by organic molecules on the anode surface and being oxidized. For example, ethanol (C₂H5OH) can be directly oxidized to acetic acid (CH3COOH) on the anode surface, and the reaction formula is: C₂H5OH + H₂O – 4e- = CH3COOH + 4H+. Indirect oxidation utilizes other strongly oxidizing substances generated by electrochemical reactions, such as hypochlorous acid (HClO), persulfate (S2O82-), etc., to oxidize organic substances. In sewage containing chloride ions, chloride ions are oxidized to chlorine gas (Cl₂) at the anode, and chlorine gas reacts with water to form hypochlorous acid. The reaction formulas are: 2Cl- – 2e- = Cl₂, Cl₂ + H₂O = HClO + H+ + Cl-. Hypochlorous acid has strong oxidizing properties and can oxidize organic substances in sewage. When treating wastewater containing petroleum pollutants, hypochlorous acid can oxidize and decompose long-chain hydrocarbon molecules in petroleum substances into small-molecule fatty acids and alcohols, further reducing their harm to the environment. - Application scenarios and cases

- Treatment of printing and dyeing wastewater

A certain printing and dyeing factory generates a large amount of printing and dyeing wastewater during the production process. The wastewater is characterized by high chromaticity, high chemical oxygen demand (COD), and complex composition. The factory adopts the electrocatalytic oxidation technology with titanium anode for wastewater treatment. During the treatment process, a coated titanium anode and a cathode form an electrolytic cell, and the printing and dyeing wastewater flows into the electrolytic cell. By adjusting operating parameters such as current density, electrolysis time, and wastewater pH value, effective treatment of the printing and dyeing wastewater is achieved. The current density set by the factory is 20mA/cm², the electrolysis time is 60 minutes, and the wastewater pH value is adjusted to 7 – 8. Under such conditions, a large number of hydroxyl radicals are generated on the surface of the coated titanium anode. These radicals react oxidatively with the organic dye molecules in the printing and dyeing wastewater, destroying the chromophoric groups of the dye molecules and significantly reducing the chromaticity of the wastewater. At the same time, the organic matter in the wastewater is oxidized and decomposed, and the COD value also drops significantly. After treatment, the chromaticity of the printing and dyeing wastewater is reduced from 1000 times before treatment to less than 50 times, meeting the discharge standard. The COD removal rate reaches over 85%, dropping from 1000mg/L before treatment to less than 150mg/L. This application case fully demonstrates the high efficiency of coated titanium anode in the treatment of printing and dyeing wastewater, which can effectively solve the pollution problem of printing and dyeing wastewater and achieve compliant discharge of the wastewater. - Treatment of wastewater containing heavy metals

When treating heavy metal – containing wastewater, the coated titanium anode can achieve the precipitation and removal of heavy metals through electrochemical reactions. Taking the treatment of chromium – containing wastewater from a power plant as an example, the wastewater of this plant contains a large amount of Cr6+, which is highly toxic. The chromium – containing wastewater is introduced into the electrolytic cell, where the coated titanium anode serves as the anode and the stainless – steel plate serves as the cathode. During the electrolysis process, the oxidation reaction of water occurs on the surface of the anode, generating oxygen and hydrogen ions. The reaction formula is: 2H₂O – 4e- = O₂↑ + 4H+. At the same time, Cr6+ gains electrons on the surface of the cathode and is reduced to Cr3+. As the electrolysis proceeds, the concentration of H+ in the solution increases, and the pH value decreases. When the pH value reaches a certain level, an appropriate amount of alkali is added to the wastewater to make Cr3+ form chromium hydroxide precipitate. The reaction formula is: Cr3+ + 3OH- = Cr(OH)3↓. In this way, the effective removal of heavy metal chromium in the chromium – containing wastewater is achieved. After treatment, the concentration of Cr6+ in the wastewater is reduced from 50mg/L before treatment to less than 0.5mg/L, meeting the discharge standard. - Domestic sewage treatmentIn the treatment of domestic sewage, the application advantages of coated titanium anode are remarkable. Taking a sewage treatment plant as an example, the plant adopts an electrocatalytic oxidation process based on coated titanium anode as the advanced treatment unit to further purify the domestic sewage after traditional biological treatment.

During the electrocatalytic oxidation process, the coated titanium anode can generate various strongly oxidizing substances, such as hydroxyl radicals and hypochlorous acid. These substances can not only oxidize and decompose the residual organic matter in domestic sewage, but also have the function of sterilization and disinfection. During the treatment process, organic pollutants in domestic sewage, such as proteins and carbohydrates, are oxidized and decomposed into carbon dioxide and water under the action of hydroxyl radicals. At the same time, hypochlorous acid can effectively kill microorganisms such as bacteria and viruses in the sewage, significantly improving the quality of the treated water.

After electrocatalytic oxidation treatment with a coated titanium anode, the COD of domestic sewage dropped from 50mg/L before treatment to less than 20mg/L, ammonia nitrogen dropped from 10mg/L to less than 2mg/L, and the number of coliforms dropped from 10,000 per liter before treatment to less than 100 per liter. The quality of the treated water meets the standards for urban landscape water and can be used for urban greening, road spraying, etc., realizing the recycling of water resources.

Applications in seawater desalination

Principle of preventing chlorine corrosion

Principle of preventing chlorine corrosion

In the seawater desalination process, seawater is rich in a large amount of chloride ions. Under specific conditions, these chloride ions are prone to an oxidation reaction to generate chlorine gas. Chlorine gas is highly corrosive and can cause serious corrosion damage to seawater desalination equipment, affecting the service life and operational stability of the equipment. The coated titanium anode plays a crucial role in this process. Its principle of preventing chlorine corrosion is based on unique electrochemical reactions and catalytic properties.

When seawater flows through the electrolysis device, under the action of an electric field, anions in the seawater (mainly chloride ions, Cl-) move towards the anode. On the surface of the coated titanium anode, water molecules undergo an electrolysis reaction, and the reaction formula is: 2H₂O – 4e⁻ = O₂↑ + 4H⁺. At the same time, due to the special catalytic activity of the mixed metal oxide coating (such as the platinum coating) on the surface of the coated titanium anode, it can preferentially catalyze the oxidation reaction of water molecules, making the oxygen evolution reaction more likely to occur. This inhibits the oxidation reaction of chloride ions and reduces the generation of chlorine gas. In a certain seawater desalination project, after using a platinum – titanium anode, the amount of chlorine gas generated from chloride ions in the seawater decreased by 80% compared to when it was not used.

Even if a small amount of chlorine gas is generated, the surface structure and chemical properties of the coated titanium anode can effectively resist the corrosion of chlorine gas. The titanium substrate itself has good corrosion resistance, and the surface mixed metal oxide coating further enhances its corrosion resistance. The coating can form a dense protective film on the surface of the titanium substrate, preventing direct contact between chlorine gas and the titanium substrate, thus protecting the titanium substrate from corrosion. In a high-concentration chlorine gas environment, the corrosion rate of the coated titanium anode is only 1/5 that of a common metal anode.

Applications in Metal Extraction and Refining

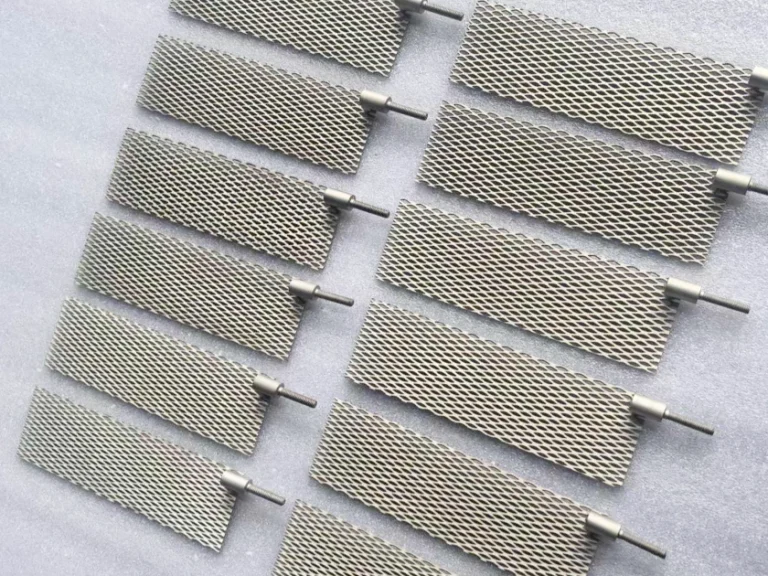

- Applications in lithium extraction

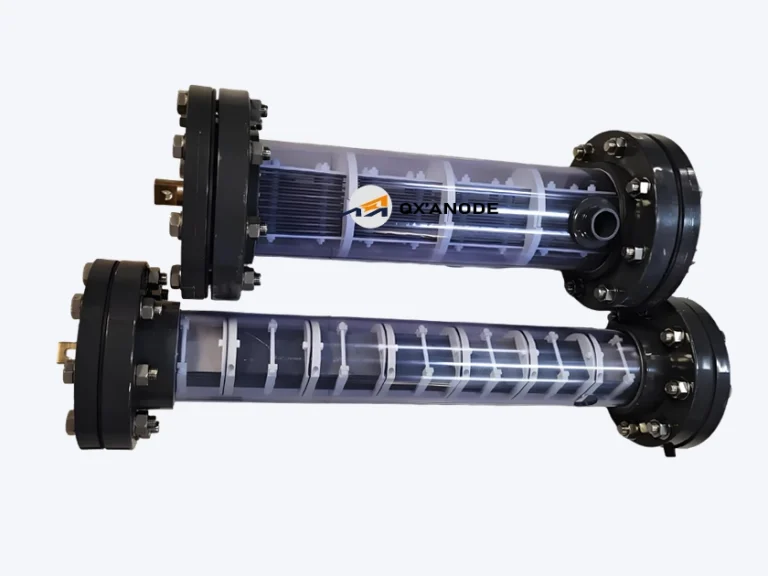

In a lithium – battery material factory, the extraction of lithium is a crucial step, and the coated titanium anode plays an important role in this process. Taking a certain lithium – battery material factory as an example, the factory uses lithium – containing brine solution as the raw material for lithium extraction. During the electrolysis process, an iridium – titanium anode is used.

When an electric current passes through a lithium – containing halide aqueous solution, an oxidation reaction occurs on the anode surface. Chloride ions in the halide aqueous solution lose electrons on the anode surface to generate chlorine gas, and the reaction formula is: 2Cl⁻ – 2e⁻ = Cl₂↑. The iridium oxide coating on the surface of the iridium – titanium anode has high catalytic activity, which can accelerate the discharge reaction of chloride ions and enable the reaction to proceed efficiently at a lower voltage. Compared with traditional graphite electrodes, after using the iridium – titanium anode, the lithium extraction efficiency has increased by 35%. This is because the high electrical conductivity of the titanium anode ensures a uniform distribution of current on the electrode surface, enabling the electrochemical reaction to proceed more fully. However, due to the relatively low electrical conductivity and catalytic activity of the graphite electrode, the lithium extraction efficiency is low. - Applications in the refining of other metals

In the copper refining process, traditional anode materials have some limitations. For example, some of the anodes used will dissolve during the electrolysis process, leading to an increase in impurities in the electrolyte and affecting the purity of copper. However, due to the good stability and catalytic activity of the mixed metal oxide coating on its surface, the coated titanium anode can remain stable during the electrolysis process and is not easy to dissolve. This helps to improve the refining purity of copper. In the simulation experiment, when the coated titanium anode was used for copper refining, the purity of the obtained copper was increased by 0.5% compared with that using the traditional anode. The coated titanium anode can also improve the electrolysis efficiency and reduce energy consumption. Due to its high catalytic activity, it can reduce the overpotential of the electrolysis reaction, enabling the reaction to proceed at a lower voltage, thus reducing power consumption.In the refining of nickel, a similar situation also exists. The refining of nickel requires an electrochemical reaction to take place in a specific electrolyte. The application of coated titanium anode can improve the conditions for the electrochemical reaction. Their good electrical conductivity and corrosion resistance can ensure a uniform distribution of current and prevent the anode from being corroded in the highly corrosive electrolyte. This helps to improve the quality and efficiency of nickel refining. In actual production, if coated titanium anode are used, it is expected to shorten the nickel refining time by 15% and increase the purity of nickel at the same time. With the continuous increase in the requirements for metal purity and production efficiency, coated titanium anode have broad application prospects in the field of metal refining such as copper and nickel, and are expected to bring new technological changes to the metal refining industry.

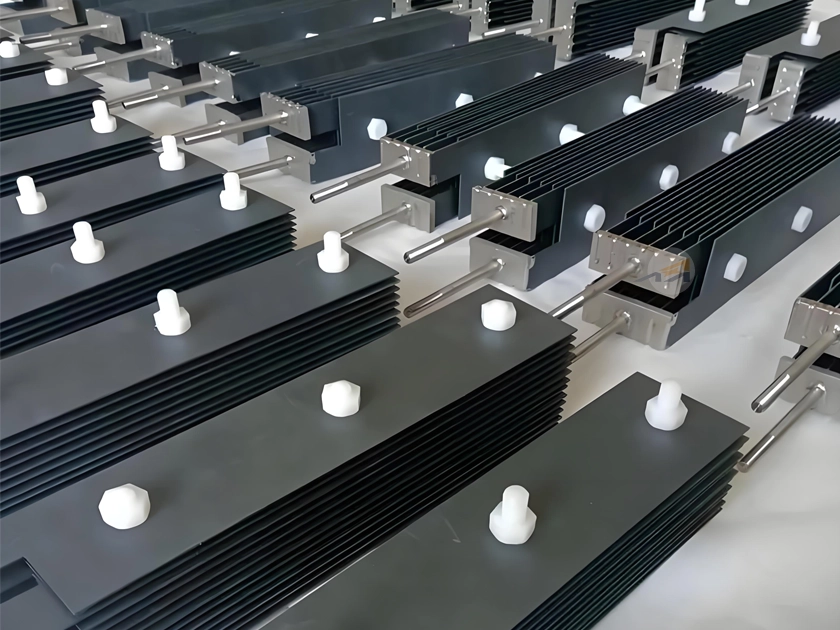

As a core material in fields such as water electrolysis for hydrogen production and the chlor-alkali industry, the industrialization process of titanium anode faces multiple challenges. The high cost of raw materials is the primary constraining factor. The prices of platinum group precious metals, as the main raw materials, remain high, directly driving up the manufacturing cost of titanium anode. The complexity of the production process further exacerbates the difficulty of industrialization. Many factories lack sufficient production experience, and the insufficient degree of standardization leads to fluctuations in product performance. It is difficult to ensure consistency between different batches, which affects the reliability of large-scale applications.

Why Choose Qixin titanium anode

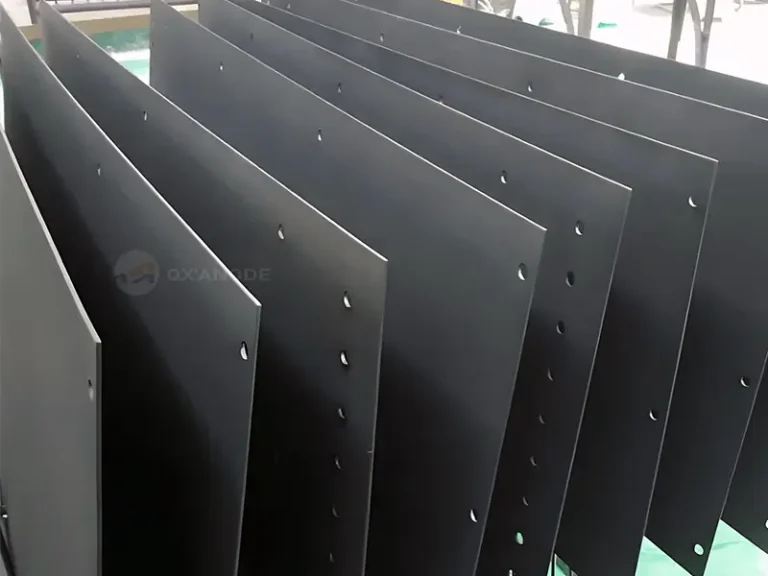

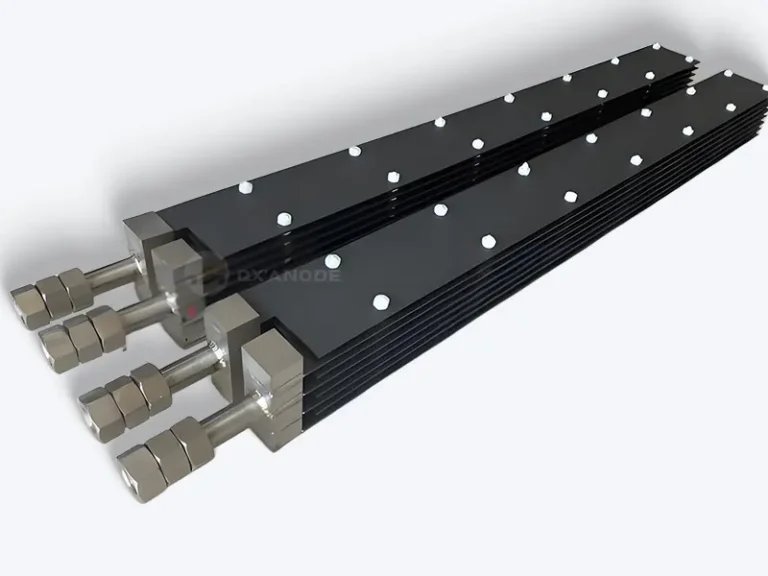

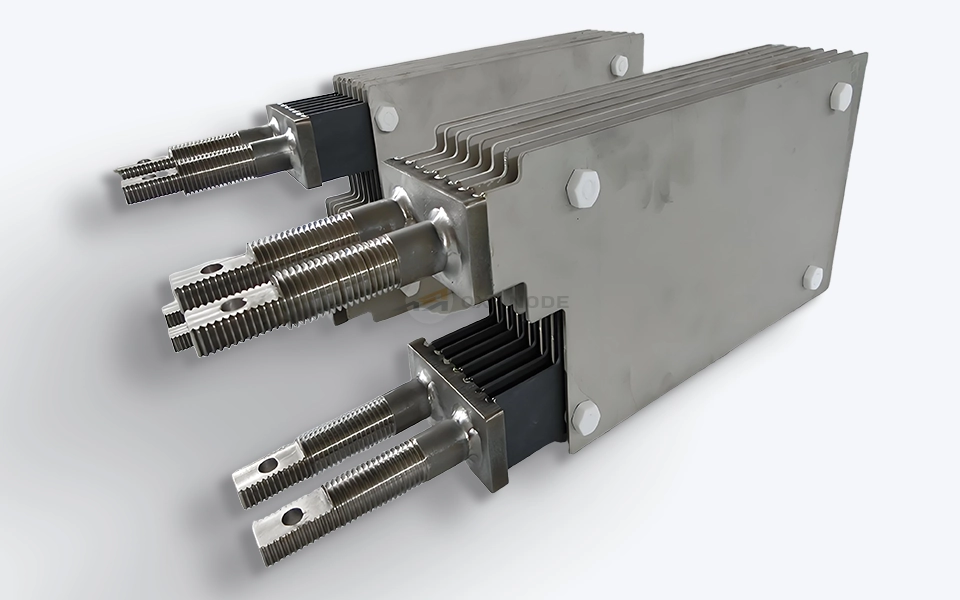

Qixin Titanium is a manufacturer of titanium anodes from China., focusing on the R&D, manufacturing and application of Mixed Metal Oxide (MMO) coated titanium anodes.

Founded in 2006, with over 20 years of manufacturing experience, we provide stable and reliable titanium anode products suitable for multiple scenarios. We help enterprises improve electrolysis efficiency, reduce operating costs, and offer personalized customization to ensure long-term stable operation.

Say Hello

Get In Touch

Don’t Hesitate to contact Us anytime with questions.