Titanium Anode Laboratory

Research & development

Independent research and development

Increase investment in research and development, innovate the R&D mechanisms, and ensure the implementation of the company’s high-tech strategy for precious metal oxide coatings. This will foster the company’s core competitiveness and generate high value and sustained growth for the enterprise.

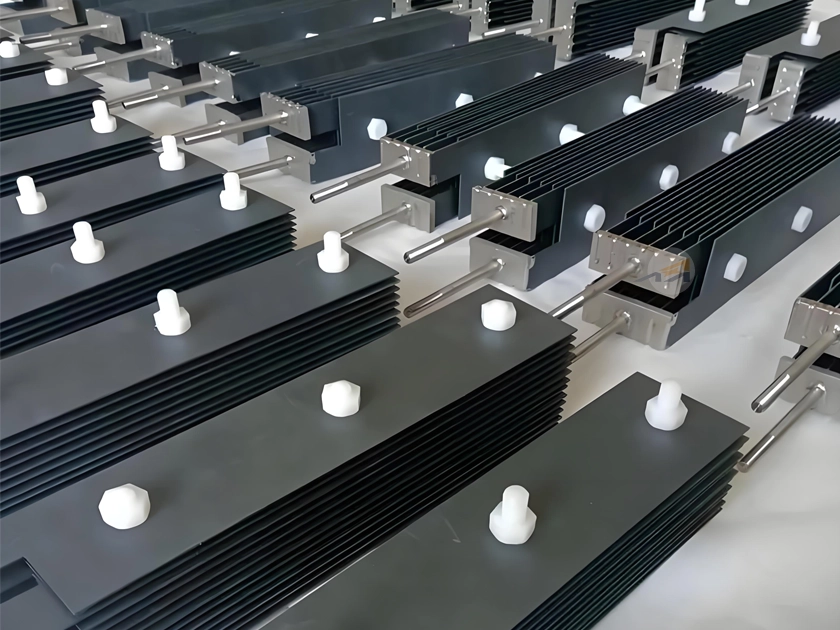

Electrolytic cell

Water Test Kits

spectrograph

Research and Development of Coated Titanium Anodes

Increasing investment in research and development is an effective way to enhance a company’s competitiveness. The core competitiveness of modern enterprises lies in the innovation of technology and the mastery of key technologies.

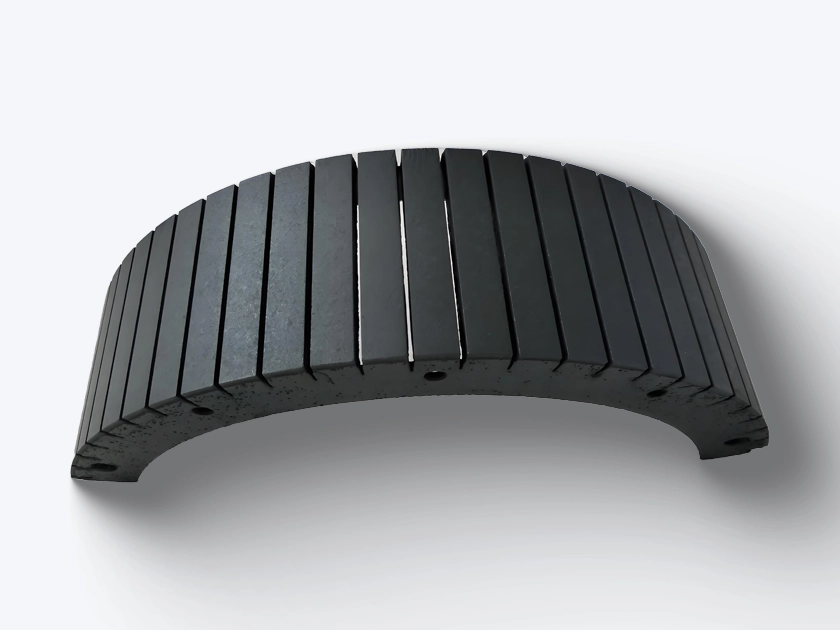

In fields such as the electrochemical industry, environmental protection water treatment, and new energy, titanium anodes, as core functional components, their performance directly determines the operating efficiency of equipment and the level of green development in the industry. With the research and development of titanium anodes as the strategic core, through technological innovation and systematic layout, we will continue to promote the technological iteration of titanium anodes and inject core impetus into the high-quality development of the industry.

The research and development of titanium anodes needs to span multiple disciplines such as materials science, electrochemical engineering, and precision manufacturing. It is difficult for a single enterprise to cover the technical needs of the entire industry chain. We took the lead in breaking down R&D barriers and jointly built a “collaborative innovation system” with materials research institutes, electrochemical laboratories, and upstream and downstream enterprises in the industrial chain. By establishing a platform for sharing the transformation of titanium anode technological achievements, we have realized the virtual integration of R&D resources relying on Internet technology – incorporating core resources such as coating electrochemical performance testing data and pilot production parameters into the collaborative network, forming cross-regional and cross-institutional R&D collaboration for titanium anodes.

This collaborative model not only solves the industry pain point of “disconnection between basic research and industrial application” in titanium anode R&D, but also achieves a multiple improvement in R&D efficiency. For example, in the research and development of precious metal oxide coatings, by sharing electrocatalytic activity test data from different institutions, the formula optimization cycle that would take 18 months under the traditional model was completed in only 6 months, successfully increasing the electrocatalytic efficiency of the titanium anode coating by 10%.

Focus on tackling core technologies and making breakthroughs in titanium anode polarity

The core technical barriers of titanium anodes lie in the coating material system and preparation process. We focus our research and development efforts on two main directions:

- Precise regulation of precious metal oxide coatings. Aiming at the problems of “weak bonding force and high loss rate” in traditional coatings, the R&D team optimized the coating microstructure through multi-layer deposition technology to achieve the combination of precious metals (platinum, iridium) and titanium substrates, reducing the loss rate of the coating under strong acid and high current density working conditions.

- Systematic research and development of precursor materials for platinum-coated titanium electrodes. Breaking through the bottleneck of “poor solubility and uneven thermal decomposition” of traditional precursor materials, a new type of organometallic complex precursor was developed, which not only improved the uniformity of the coating preparation process, but also reduced the platinum usage by 5%, significantly lowering the production cost of titanium anodes and laying a foundation for large scale applications.

- Systematic research and development of precursor materials for platinum-coated titanium electrodes. Breaking through the bottleneck of “poor solubility and uneven thermal decomposition” of traditional precursor materials, a new type of organometallic complex precursor was developed, which not only improved the uniformity of the coating preparation process, but also reduced the platinum usage by 5%, significantly lowering the production cost of titanium anodes and laying a foundation for large-scale applications.