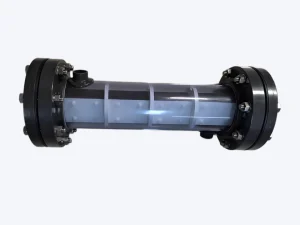

Titanium anodes for electrolyzing brine to produce chlorine

The electrolysis of water to produce chlorine plays a crucial role in the field of water treatment. As the global water shortage situation continues to intensify, efficient and economical water disinfection technologies have become an urgent need. The electrolysis of water to produce chlorine has gradually become a key technology in the field of water treatment due to its significant advantages such as readily available raw materials, simple operation, and high purity of chlorine gas.

The basic principle of producing chlorine through electrolysis of water

The core process of electrolyzing water to produce chlorine involves electrolyzing a salt solution (i.e., sodium chloride solution), thereby generating chlorine gas (Cl₂), hydrogen gas (H₂), and sodium hydroxide (NaOH). The chemical reaction equation for this process is: 2NaCl + 2H₂O → 2NaOH + Cl₂ + H₂. During the electrolysis process, chloride ions (Cl⁻) undergo oxidation reactions at the anode, generating chlorine gas; while water molecules undergo reduction reactions at the cathode, producing hydrogen gas and hydroxide ions (OH⁻). These products can be directly used in the disinfection stage and PH value.

The technical advantages of electrolyzing water to produce chlorine

- Raw materials are readily available

The salt (sodium chloride) used in the process of electrolyzing water to produce chlorine is a widely accessible substance. It is not only affordable but also easy to obtain. Especially in coastal areas, people can directly use the sodium chloride in seawater for electrolysis, further reducing the production cost.

- Safe and worry free

The electrolysis of water to produce chlorine generates chlorine gas on-site immediately, eliminating the need for storage and transportation of liquid chlorine, thereby significantly reducing safety risks and ensuring the safety of the operation process.

- Pure and efficient

The chlorine gas obtained through electrolyzing water is of extremely high purity and can be directly used for water disinfection without the need for additional purification. The disinfection effect is remarkable.

- Flexibility and Applicability

Compared with the traditional liquid chlorine disinfection method, the electrolysis water chlorine production technology demonstrates greater flexibility and applicability, especially in scenarios where frequent disinfection is required or where safety standards are high.