Electrolytic Salt Disinfection for Pools

A healthier, more economical, and eco-friendly way to keep your pool clean and crystal clear.

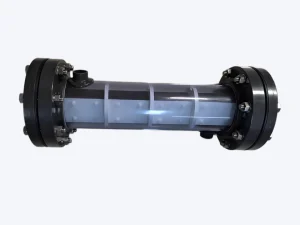

Titanium anode for pool water disinfection

OVERVIEW

Revolutionizing Pool Disinfection

Millions of pool owners worldwide are switching to electrolytic salt disinfection for a healthier and more sustainable swimming experience.

Electrolytic Salt Disinfection

An advanced method that passes an electric current through a saltwater solution to generate hypochlorous acid. This process is more efficient, eco-friendly, and gentler on skin and equipment.

How It Works

By electrolyzing salt, the system produces chloride ions, hydrogen ions, and hypochlorous acid – the same disinfectant produced by traditional methods but without the harsh side effects.

The Science Behind Electrolytic Disinfection

During electrolysis, an electric current is passedthrough a saltwater solution. At the anode, chloride ions (Cl-) are generated, while at the cathode, hydroxide ions (OH+) are produced. This process effectively mimics the disinfectant properties of traditional chlorine-based systems but with fewer drawbacks.

TECHNOLOGY

Advanced Titanium Anode Technology

Our proprietary mixed metal oxide (MMO) coated titanium anode delivers superior performance and durability.

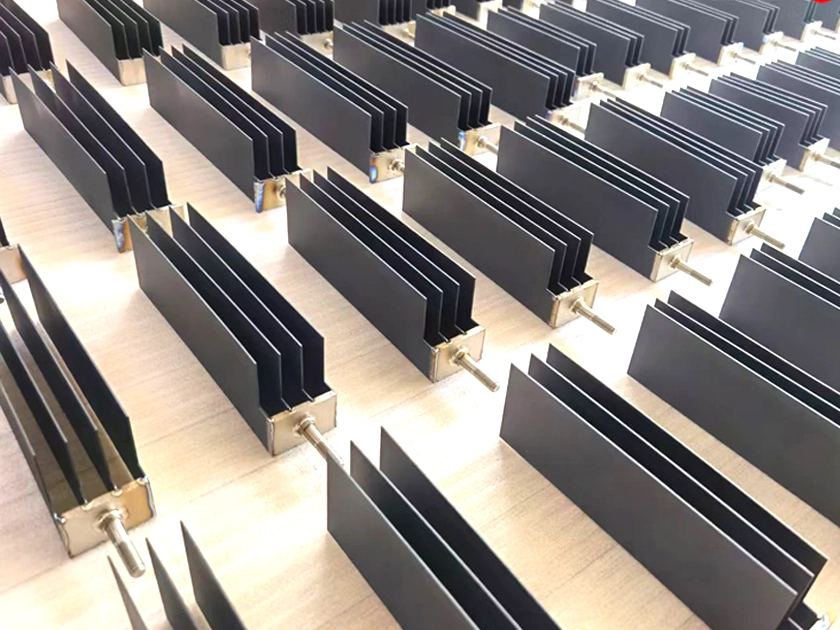

Mixed Metal Oxide (MMO) Coated Titanium Anodes

Our advanced titanium anodes are coated with a proprietary mix of metal oxides that significantly enhance chlorine production efficiency while maintaining excellent stability.

Enhanced Chlorine Production

Our MMO coated titanium anodes produce up to 50% more chlorine compared to standard anodes, ensuring optimal disinfection with minimal energy consumption.

Exceptional Durability

The coating is firmly bonded to the titanium substrate, resisting corrosion and wear even in harsh pool environments, resulting in a longer service life.

Cost-Effective Solution

With self-contained precursor materials for the coating and advanced manufacturing processes, our anodes offer superior performance at a competitive price.

Electrolytic Salt Disinfection vs. Traditional Chlorination

Feature | Electrolytic Salt | Traditional Chlorine |

|---|---|---|

Skin & Eye Irritation | ||

Chlorine Odor | ||

Equipment Corrosion | ||

Cost Over Time | ||

Environmental Impact | ||

Maintenance Effort |

PROCESS

How Electrolytic Salt Disinfection Works

A step-by-step guide to our advanced pool water treatment system.

- Salt Addition

Salt (sodium chloride) is added to the pool water at a concentration of 4,000-6,000 PPM (4-6 kg per cubic meter of water). This is a much lower concentration than seawater. - Electrolysis Process

The pool water is circulated through an electrolytic cell where an electric current is applied. At the anode, chloride ions (Cl-) are generated, and at the cathode, hydroxide ions (OH+) are produced. - Hypochlorous Acid Generation

The electrolysis process produces hypochlorous acid (HOCl), the same powerful disinfectant produced by traditional chlorine-based systems, but through a safer and more controlled method. - Disinfection & Oxidation

Hypochlorous acid effectively kills bacteria, viruses, and algae. Additionally, the system helps degrade harmful chloramines and other disinfection byproducts through oxidation. - Recycling & Reuse

After disinfection, the hypochlorous acid reverts back to salt, creating a closed-loop system that continuously recycles the salt, minimizing waste and the need for frequent chemical additions.