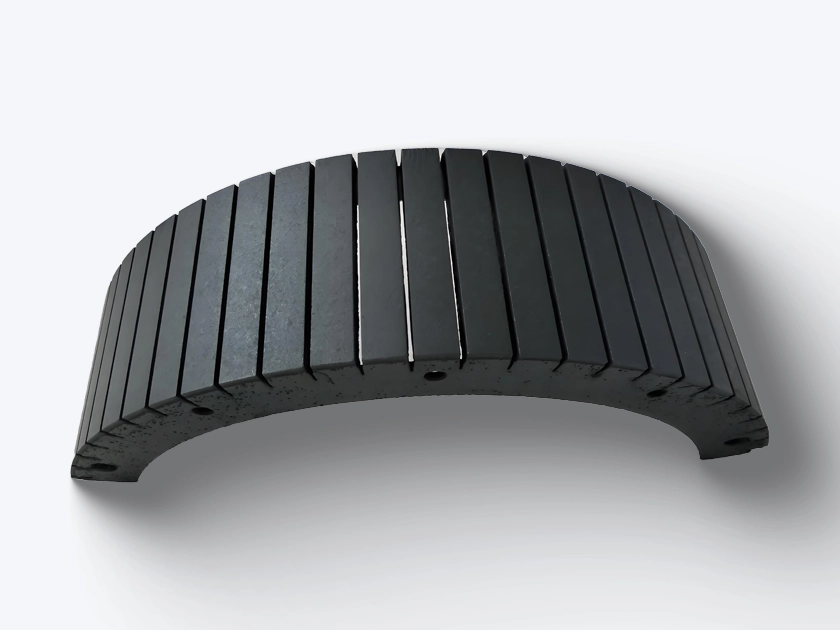

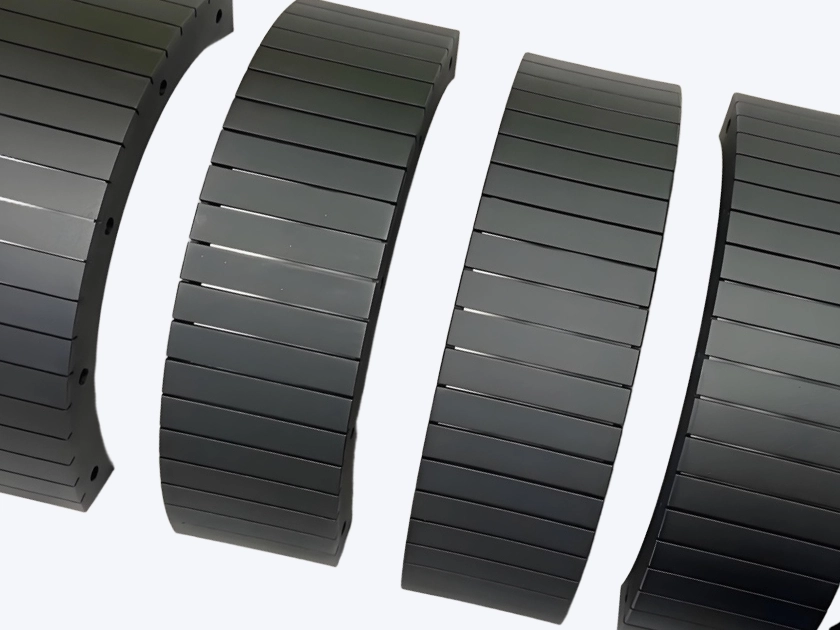

Titanium anode for industrial electroplating

In all electroplating application fields, the working principle is basically the same. The required plating metal is dissolved in the electrolyte, the metal substrate to be plated serves as the negative electrode, and the anode is used as the positive electrode, thus forming a complete current transmission cycle. The chemical reaction that occurs simultaneously with electroplating in the electroplating tank is the release of oxygen at the anode surface. For example: copper-nickel electroplating; decorative electroplating (trivalent chromium electroplating, jewelry, eyewear, household hardware electroplating); rack plating and barrel plating processes for different application fields; electroforming (dental products, contact bushings and contacts, etc.); hard chromium electroplating; special electroplating; electrophoretic coating; tin-copper electroplating, etc.

The Versatile World of Titanium Anodes: A New Era in Electroplating Hardware

Introduction to Electroplating

Electroplating is a crucial process employed in various industries to enhance the properties of materials, primarily by depositing a layer of metal onto a substrate. This technique involves the use of an electric current to reduce cations of a desired metal from a solution and form a coherent metallic coating. The most common applications of electroplating include improving corrosion resistance, aesthetics, conductivity, and wear resistance, which are paramount in hardware manufacturing and numerous other sectors.

Historically, the materials used in electroplating operations have primarily included traditional metals such as gold, silver, nickel, and chromium. Each of these materials offers specific benefits suitable for various applications. For instance, nickel plating is widely utilized to provide corrosion resistance, while gold plating is favored for its excellent conductivity and aesthetic appeal. However, the limitations inherent in these conventional materials, such as susceptibility to corrosion and reduced operational efficiency, have sparked the quest for more advanced solutions.

The advent of titanium anodes represents a significant advancement in electroplating technology. Unlike traditional plating materials that can degrade over time and create waste, titanium anodes are known for their exceptional durability and resistance to corrosion. Utilizing titanium in the electroplating process not only extends the lifespan of the anodes but also enhances the overall efficiency of the plating process. As industries continue to seek ways to improve sustainability and operational performance, the adoption of titanium anodes stands to revolutionize current practices. Through this introduction of innovative materials, such as titanium, we can anticipate a future of electroplating characterized by enhanced quality and performance in applications ranging from electronics to automotive parts.

Understanding Titanium Anodes

Titanium anodes are specialized devices utilized in various electroplating applications. These anodes are composed primarily of titanium, a metal known for its remarkable strength-to-weight ratio, exceptional corrosion resistance, and impressive durability. The unique properties of titanium make it an ideal choice for environments where exposure to corrosive agents is prevalent. In the context of electroplating, titanium anodes serve as a crucial component, facilitating the transfer of electrical current necessary for the plating process.

Structurally, titanium anodes typically feature a substrate of pure titanium, often coated with a layer of precious metal such as platinum or iridium. This coating enhances the anode’s conductivity while further improving its corrosion resistance. The dual-layer structure allows these anodes to maintain performance over extended periods, conserving both energy and resources during electroplating operations. In contrast to traditional anodes, such as lead or graphite, titanium anodes exhibit significantly less wear and require less maintenance, making them a cost-effective solution for manufacturers.

The functionality of titanium anodes in the electroplating process is rooted in their ability to conduct electricity efficiently. When a direct current is applied, these anodes facilitate the movement of metal ions from the electrolyte to the workpiece being plated. The oxidation reactions that occur at the surface of the titanium anode release electrons, which play a critical role in the deposition of the plating material. This process ensures a uniform and consistent coating, essential for achieving high-quality results in various industrial applications.

Due to their durability, resistance to chemical attack, and efficiency, titanium anodes have become the preferred choice in many electroplating scenarios. They not only contribute to improved plating quality but also enhance the overall sustainability of the manufacturing process by reducing waste and extending the lifespan of electroplating setups.

Advantages of Titanium Anodes in Electroplating

Titanium anodes have emerged as a pivotal component in the electroplating industry, offering a myriad of advantages that significantly enhance the electroplating process. One of the primary benefits of utilizing titanium anodes is their increased efficiency. Given their excellent conductivity and resistance to corrosion, titanium anodes can operate at higher current densities without succumbing to degradation or reduced performance. This efficiency translates into shorter processing times, which can lead to higher productivity and reduced energy consumption.

Moreover, titanium anodes contribute to the improved quality of the final product. They produce a more uniform plating layer compared to traditional anodes, which can result in a superior surface finish and better adhesion of the electroplated material. This consistency is crucial in industries where precision is paramount, such as aerospace and medical applications, where the integrity of the plated components is critical.

Another significant advantage of titanium anodes is their lower maintenance costs. Unlike other materials that may require frequent replacement due to wear and tear, titanium anodes are renowned for their durability. Their extended lifespan means that businesses can allocate fewer resources to maintenance and replacement, leading to a more cost-effective electroplating operation over time. Additionally, the reduction in anode replacement frequency also minimizes downtime, further enhancing operational efficiency.

Lastly, the extended lifespan of both titanium anodes and the electroplating equipment results in long-term savings. By investing in titanium anodes, companies are not only ensuring enhanced performance but are also contributing to a more sustainable production method by reducing waste and the environmental impact associated with frequently replacing anodes. Overall, the integration of titanium anodes represents a significant advancement in the field of electroplating hardware, positioning them as a preferred choice for manufacturers seeking reliability and excellence in their plating processes.

Applications in Hardware Electroplating

Titanium anodes have emerged as a pivotal component in the field of hardware electroplating, offering enhanced performance and longevity across various sectors. Their utility spans prominent industries such as automotive, aerospace, and electronics, where high-quality surface finishes and durability are paramount. In automotive applications, titanium anodes are utilized to improve the corrosion resistance of components, thereby extending the lifespan of parts such as engine blocks and body panels. The ability to produce uniform coatings with titanium anodes greatly reduces the risks of pitting and overall wear, ensuring that vehicles maintain their aesthetic and functional integrity over time.

In the aerospace sector, the demand for lightweight yet strong materials drives the use of titanium anodes in the electroplating process. Components that undergo intense stress and exposure to harsh environments, such as turbine blades and structural frames, benefit significantly from the application of titanium anodes. These anodes facilitate the electrodeposition of protective coatings that enhance fatigue resistance while minimizing weight, ultimately contributing to improved fuel efficiency and performance in aircraft. The ability of titanium to withstand extreme conditions makes it an ideal choice for electroplating applications in this industry.

The electronics sector also reaps the benefits of titanium anodes, especially in the production of conductive and solderable coatings for various electronic components. From circuit boards to connectors, the application of titanium anodes enables a high-quality deposition process that ensures superior electrical conductivity and adhesion properties. This advancement not only enhances the performance of electronic devices but also ensures their reliability, which is crucial in today’s fast-paced technological landscape. Thus, the integration of titanium anodes in hardware electroplating serves as a catalyst for innovation across multiple industries, establishing a new standard for quality and efficiency.

Comparative Analysis: Titanium vs. Other Anode Materials

When evaluating anode materials, specifically in the context of electroplating, it is vital to consider various factors such as cost, environmental impact, performance, and longevity. Traditionally, materials like lead, tin, and graphite have been used extensively in anode production; however, titanium anodes are gaining popularity as a superior alternative based on several critical attributes.

Cost is often a primary concern when selecting materials. Traditional anodes like lead and tin are generally less expensive to produce initially. However, the comprehensive ownership costs over time can paint a different picture. Titanium anodes, while having a higher upfront cost, often result in significant savings in the long term due to their durability and performance efficiency. As titanium is highly resistant to corrosion, it outperforms the more reactive traditional materials, which may require frequent replacement or maintenance, thus leading to higher cumulative costs.

Environmental impact is another critical consideration. Titanium is known for its environmentally friendly profile. In contrast, lead poses long-term health risks and environmental hazards when improperly disposed of, making titanium a more sustainable choice. Additionally, graphite, although used widely, generates dust and particulates during handling that can be harmful to workers involved in electroplating processes.

When it comes to performance, titanium anodes show superior efficacy in electroplating applications by providing a consistent current density and a longer lifespan than traditional materials. Their corrosion resistance leads to stable electrochemical performance, which is essential for achieving high-quality plating results without the risk of contamination. In terms of longevity, titanium can withstand harsh electrolytic environments far better than lead or tin, often lasting several years or decades under similar conditions.

In summary, while traditional anode materials like lead, tin, and graphite have served their purpose in electroplating, titanium emerges as a consistently superior choice due to its cost-efficient longevity, reduced environmental impact, and enhanced performance capabilities. This comparative analysis illustrates the advantages of transitioning to titanium anodes for modern electroplating applications.

Challenges and Considerations

While titanium anodes have gained popularity in the electroplating industry due to their numerous advantages, there are several challenges and considerations that manufacturers should be aware of when contemplating their use. One of the primary obstacles is the initial cost investment associated with titanium anodes. Compared to traditional anodes, titanium options tend to have a higher upfront cost. This investment may deter some manufacturers, especially smaller operations, from making the switch, despite the long-term savings and performance benefits that titanium anodes can provide.

Another consideration is the handling and installation of titanium anodes. Given their lighter weight and unique chemical properties, proper handling procedures must be established to prevent damage during transport and installation. Unlike more conventional materials, titanium requires specialized techniques for welding and mounting which might necessitate additional training for personnel involved in setup and maintenance. Thus, investing in staff education is a critical factor to ensure optimal performance of titanium anodes in existing electroplating systems.

Compatibility with current electroplating systems is also an important factor manufacturers must assess. Depending on the specific setup and materials in use, titanium anodes may require modifications to existing frameworks or processes to achieve the desired electroplating results. Collaborating with suppliers and industry experts can help address potential issues with compatibility, allowing for a smoother transition to titanium anodes.

In light of these challenges, manufacturers must undertake thorough evaluations of their operational needs and system compatibility before adopting titanium anodes. By addressing these considerations proactively, manufacturers can fully leverage the advantages of titanium in their electroplating processes, ultimately paving the way for enhanced efficiency and effectiveness in their operations.

Future Trends in Electroplating Technology

The electroplating industry stands at the brink of transformation, propelled by advancements in technology and an increasing emphasis on sustainability. As the demand for enhanced productivity and eco-friendly practices grows, the introduction of titanium anodes is becoming integral to future developments. Titanium anodes are recognized for their corrosion resistance and longevity, making them an ideal choice for various electroplating applications.

One of the significant trends shaping the future of electroplating is automation. As industries seek to boost efficiency and reduce labor costs, automated systems are being adopted. These systems facilitate consistent and precise plating processes, minimizing human error. Titanium anodes seamlessly integrate into these automated systems, providing superior performance and reliability. Their compatibility with advanced plating equipment ensures that the electroplating industry can harness high levels of productivity while maintaining quality standards.

Sustainability is another critical focus area for the electroplating industry. Traditional electroplating methods often involve toxic chemicals and energy-intensive processes, prompting manufacturers to seek greener alternatives. The utilization of titanium anodes aligns perfectly with these sustainability goals, as they can be utilized in less hazardous plating solutions and often require less energy compared to conventional electrodes. This shift not only reduces environmental impact but also enhances the overall safety of electroplating operations.

Innovation is also pivotal in driving future trends within the industry. Research and development are focusing on advanced materials and techniques, aiming to improve electroplating efficiency and effectiveness. Emerging technologies, such as electroplating in microgravity or hybrid plating techniques, may further diversify applications and optimize results. As these innovations unfold, the role of titanium anodes will likely evolve, enabling more sophisticated and diverse electroplating solutions.

Case Studies of Successful Implementations

The adoption of titanium anodes in the electroplating industry has yielded significant benefits, as evidenced by various case studies. One prominent example is the success story of a major automotive manufacturer that sought to enhance the efficiency of its plating processes. Faced with decreasing operational efficiency and increasing waste disposal costs due to the use of traditional lead anodes, the company decided to transition to titanium anodes. This shift not only improved the energy consumption during plating but also contributed to a considerable reduction in sludge production, resulting in lower disposal expenses. Consequently, the manufacturer experienced a notable increase in overall productivity and a reduced environmental footprint.

Another case involves a leading provider of electronic components that aimed to refine their process for plating circuit boards. The challenge presented by the need for high precision in plating thickness posed significant limitations with the previous anode materials. The integration of titanium anodes allowed for a more uniform current distribution, which ultimately enhanced the plating quality while reducing defects. This improvement led to increased customer satisfaction and fewer returns, as the products met stringent quality standards more consistently.

In the field of marine applications, a company specializing in shipbuilding turned to titanium anodes to combat corrosion issues related to conventional metal anodes. By implementing titanium anodes, the shipbuilder observed a remarkable extension in the lifespan of the vessels, resulting in reduced maintenance and repair costs over time. The decision to use titanium also contributed to better adherence to environmental regulations due to decreased harmful emissions. These varied case studies highlight the versatility and efficiency of titanium anodes, showcasing not only their adaptability across different sectors but also their role in meeting modern challenges of sustainability and performance in electroplating processes. As such, companies across multiple industries are increasingly recognizing the advantages of incorporating titanium anodes into their operations.

Conclusion: The Future of Hardware with Titanium Anodes

In assessing the transformative potential of titanium anodes within the electroplating sector, it is evident that this innovative material stands poised to significantly alter the landscape of hardware manufacturing. Titanium anodes, known for their exceptional resistance to corrosion and extended lifespan, present a robust alternative to traditional materials. The use of titanium not only enhances the durability of the anodes but also contributes to more efficient electroplating processes, thereby offering manufacturers both economic and environmental advantages.

The versatility of titanium anodes has been highlighted throughout this discussion, showcasing their applicability across various industries, including automotive, aerospace, and electronics. Manufacturers are likely to find that transitioning to titanium anodes enables not only superior performance but also a reduction in maintenance costs and downtime. This shift could ultimately lead to a more sustainable approach in hardware production, aligning with the growing emphasis on eco-friendly practices across all sectors.

Furthermore, the adoption of titanium anodes reflects a broader trend toward embracing advanced materials in manufacturing processes. As hardware companies continue to innovate, integrating titanium anodes into their electroplating systems may provide a competitive edge, fostering improved product quality and customer satisfaction. The scalability of titanium technology ensures that it can be employed effectively by both large-scale manufacturers and smaller enterprises alike.

As we look to the future, it is clear that the transition to titanium anodes will not merely enhance electroplating operations but will also pave the way for more resilient, sustainable, and efficient hardware solutions. Therefore, it is incumbent upon hardware manufacturers to consider the significant advantages offered by titanium anodes, positioning themselves at the forefront of this new era in electroplating

Say Hello

Get In Touch

Don’t Hesitate to contact Us anytime with questions.