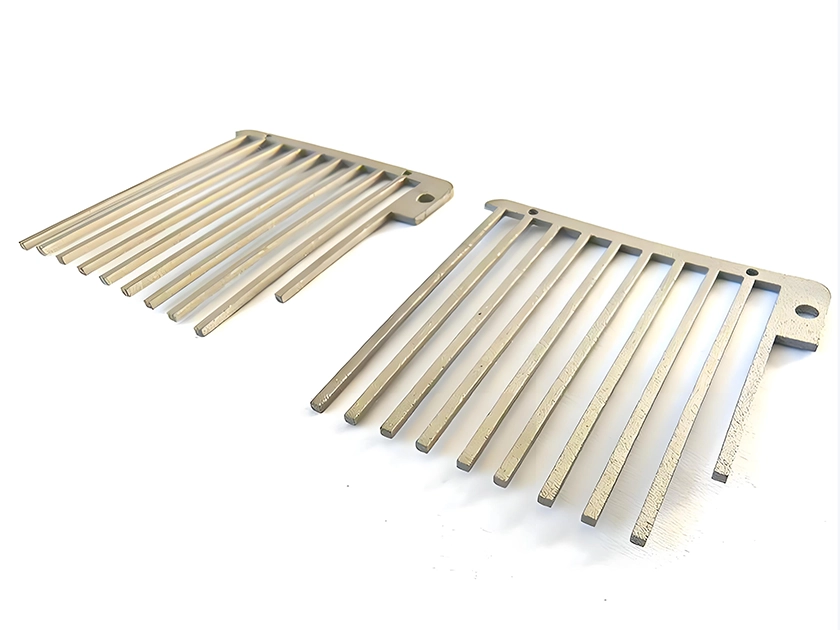

Titanium anodes for electrolytic hydrogen production

Hydrogen production through electrolysis mainly utilizes direct current to split water molecules. In this process, the titanium anode plays a crucial role. When electricity is applied, water molecules react near the anode, and water is oxidized to produce oxygen and hydrogen ions. The coating on the surface of the titanium anode helps accelerate the reaction and improve the efficiency of the hydrogen production process. On the cathode, a reduction reaction occurs, where hydrogen ions gain electrons to form hydrogen gas. The different reactions at the anode and cathode work together to achieve hydrogen production, and the performance of the titanium anode throughout the process is of vital importance.

With the increasingly severe global energy crisis and environmental pollution issues, hydrogen energy, as a clean and efficient form of energy, has attracted much attention for its development prospects. In hydrogen production technology, water electrolysis for hydrogen production is considered one of the most promising methods due to its advantages of simple process, high product purity, and no pollution. Titanium anode, as a key material in hydrogen production through water electrolysis, exhibits significant advantages in improving electrolysis efficiency, reducing energy consumption, and extending equipment life due to its excellent corrosion resistance, conductivity, and stability. This article systematically reviews the current application status of titanium anodes in hydrogen production by water electrolysis, including their preparation process, performance evaluation, and optimization strategies. It also analyzes the practical application effects of titanium anodes in depth through practical cases. Research has shown that by optimizing the preparation process and coating composition of titanium anodes, their comprehensive performance can be significantly improved, thereby promoting the development of water electrolysis hydrogen production technology. Meanwhile, the potential applications of titanium anodes in emerging fields such as wastewater treatment and resource recovery are also worth further exploration. In the future, with the continuous advancement of preparation technology and the expansion of application fields, titanium anodes are expected to play a more important role in the hydrogen energy industry, contributing to the transformation and sustainable development of the global energy structure.

Titanium anodes, with their unique physical and chemical properties, play a crucial role in the field of hydrogen production through water electrolysis. These properties mainly include corrosion resistance, conductivity, mechanical strength, and stability. Together, they ensure the efficient and long-lasting operation of titanium anodes in harsh electrolytic environments.

The corrosion resistance of titanium anodes is one of the most prominent characteristics. During water electrolysis, the anode needs to withstand high voltages and strong oxidizing environments. Titanium anodes can operate stably in such environments for a long time, and the protective role of the precious metal oxide coating formed on their surfaces effectively reduces material corrosion . This characteristic enables titanium anodes to maintain stable performance during continuous electrolytic reactions, thereby extending the equipment’s service life and reducing maintenance costs.

In addition to corrosion resistance, titanium anodes also have excellent conductivity. In the process of electrolyzing water, good conductivity is a key factor in ensuring electrolytic efficiency. The conductivity of titanium anodes effectively reduces resistance losses during the electrolysis process, thereby improving electrolytic efficiency . This means that under the same electrolysis conditions, using titanium anodes can result in more hydrogen gas production, further enhancing the economic efficiency of water electrolysis for hydrogen production.

Titanium anodes also have high mechanical strength and stability. In the process of hydrogen production through water electrolysis, the anode needs to withstand large current densities and electrolytic pressures. The high mechanical strength of titanium anodes enables them to remain stable under such working conditions, and they are less likely to deform or be damaged. At the same time, their stability also ensures the reliability of performance during long-term operation, reducing the risk of production interruptions due to material failure.

Titanium anodes, with their corrosion resistance, conductivity, mechanical strength, and stability, demonstrate significant advantages in the field of water electrolysis for hydrogen production. These properties not only ensure the efficient operation of titanium anodes in harsh electrolytic environments but also extend the equipment’s service life, reduce maintenance costs, and further enhance the economic and feasibility of water electrolysis for hydrogen production. Therefore, the application of titanium anodes in water electrolysis technology has broad prospects and important practical significance.