Application of Titanium Anode for Electrodialysis

Material: Gr1/Gr2

Coating: RuO₂+IrO₂/IrO₂+Ta₂O₅

Operating temperature: < 60℃

Fluoride ion content: <50mg/L

Specification and size: plate-shaped, mesh-shaped, and can be adjusted according to customers’ different electrolyte, current density, and designed coating processes.

Basic Principles of Electrodialysis

Electrodialysis (ED) is an electrochemical separation technology based on ion exchange membranes. It drives ions in the solution to selectively pass through the ion exchange membranes by applying an electric field, thereby achieving the separation, purification, and concentration of substances.

Electrodialysis is a membrane separation technology based on the selective permeability of ion exchange membranes. It drives the directional migration of ions through an applied direct current electric field to achieve the separation, concentration, or purification of solutes. Its core mechanism lies in the synergistic effect between the selective permeability of ion exchange membranes and the driving force of the electric field. The ion migration process is influenced by multiple factors such as electric field strength, solution pH value, and membrane material properties.

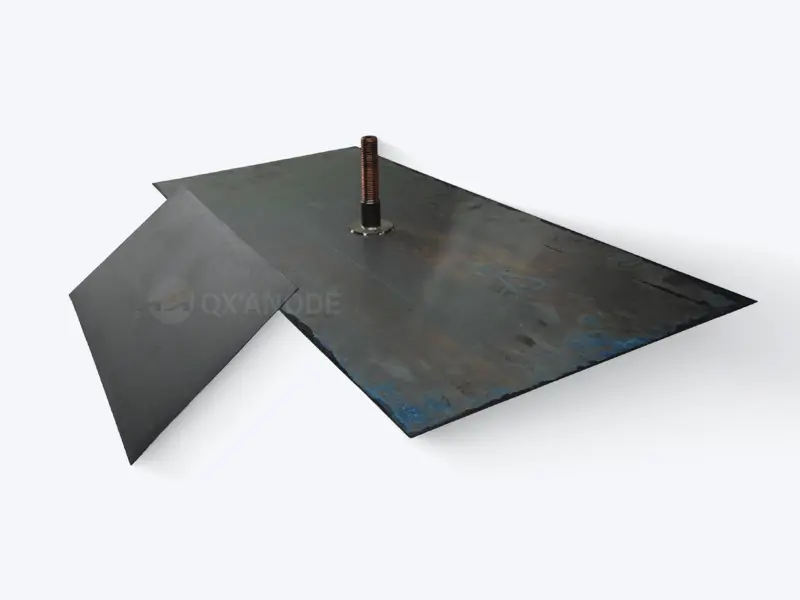

As a key component of electrodialysis devices, titanium anodes usually use commercial pure titanium plates and titanium meshes as their base materials. The conductivity and corrosion resistance are optimized through surface treatment processes, and at the same time, metal oxide coating technology is combined to further improve catalytic activity and stability.

The conductivity of titanium anodes directly affects the efficiency of electrodialysis. A highly conductive substrate can reduce electrode resistance and promote the uniform distribution of current. Meanwhile, corrosion resistance ensures their long-term stable operation in harsh electrolytic environments. A dense protective layer is formed through coating modification technology, which effectively isolates the direct contact between the electrolyte and the substrate.

Basic Principles of Titanium Anode for Electrodialysis

Electrodialysis is an electrochemical separation technology based on ion exchange membranes. An electrodialysis device mainly consists of cation exchange membranes, anion exchange membranes, titanium anodes and cathodes for electrodialysis, separators, and clamping devices, etc. In the electrodialysis device, cation exchange membranes and anion exchange membranes are arranged alternately to form fresh water compartments and concentrated water compartments. When a direct current electric field is applied across the electrodes, the cations in the solution move towards the cathode under the action of the electric field force, and the anions move towards the anode. Since cation exchange membranes only allow cations to pass through and anion exchange membranes only allow anions to pass through, the ions in the fresh water compartments will continuously migrate to the concentrated water compartments, thereby realizing the production of fresh water and the concentration of the solution.

During the electrolysis process, the titanium anode used in electrodialysis undergoes an oxidation reaction, while the cathode undergoes a reduction reaction. The anode reactions are mainly the oxygen evolution reaction from water oxidation or the chlorine evolution reaction from chloride ion oxidation, with the specific reaction formulas as follows:

Anode reaction

Oxygen evolution reaction: 2H₂O – 4e⁻ → O₂↑ + 4H⁺

Chlorine evolution reaction: 2Cl⁻ – 2e⁻ → Cl₂↑

The cathodic reaction is mainly the reductive hydrogen evolution reaction of water, and the reaction formula is as follows:

2H₂O + 2e⁻ → H₂↑ + 2OH⁻

Performance of Titanium Anode for Electrodialysis

During the electrolysis process, titanium anodes used in electrodialysis undergo oxidation reactions. The active components in the coating, such as RuO₂ and IrO₂, have high electrocatalytic activity and can adsorb reactants like H₂O and Cl⁻, promoting the progress of oxidation reactions. Titanium anode for electrodialysis have good electrical conductivity, which can transfer electrons from the titanium substrate to the reactant molecules, ensuring the smooth progress of the reaction.

- High electrocatalytic activity: It has a low oxygen evolution overpotential or chlorine evolution overpotential, which can reduce the energy consumption of the electrodialysis system and improve the separation efficiency.

- Good corrosion resistance: It has good corrosion resistance in the working environment of electrodialysis (such as acidic, alkaline, and oxidizing solutions) and can operate stably for a long time.

- High stability: During long-term use, the coating is not easy to fall off, dissolve or fail, and has a long service life.

- Good electrical conductivity: It has a low resistivity, which can reduce energy loss during electron transfer.

- Good mechanical properties: It has certain mechanical strength and flexibility, and can meet the installation and operation requirements of electrodialysis devices.

The coating materials of titanium anodes mainly include ruthenium-based and iridium-based oxides. Ruthenium-based coatings (such as RuO₂) have high electrocatalytic activity and good electrical conductivity, but their corrosion resistance is relatively weak, and they are easily oxidized and 失效 in strong oxidizing environments. Iridium-based coatings (such as IrO₂) have excellent corrosion resistance and stability, but their electrocatalytic activity is relatively low and their cost is high.

Application fields of titanium anode for electrodialysis

Electrodialysis (ED/EDR) is a membrane separation technology based on the selective permeability of ion exchange membranes. It achieves the directional migration and separation of ions in a solution through the drive of an electric field.

- Seawater desalination and brackish water desalination

- Industrial pure water / ultrapure water preparation

- Industrial Wastewater Treatment and Reuse

- Softening and Purification of Drinking Water

- Purification and Separation of Chemical Products

- Food processing and purification

- Purification and refinement of pharmaceuticals

- Marine and navigation field

Manufacturer of titanium anode for electrodialysis

Qixin Titanium is a manufacturer of titanium anodes from China., focusing on the R&D, manufacturing and application of MMO coated titanium anodes.

Qi Xin Titanium was founded in 2006., with over 20 years of manufacturing experience, we provide stable and reliable titanium anode products suitable for multiple scenarios. We help enterprises improve electrolysis efficiency, reduce operating costs, and offer personalized customization to ensure long-term stable operation.