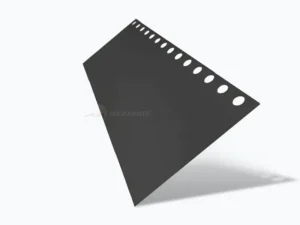

Titanium anode for electro catalytic oxidation wastewater treatment

Efficient and environmentally friendly wastewater treatment solutions lead the innovation in water treatment technology

Electrochemical catalytic oxidation technology is an efficient and environmentally friendly sewage treatment method. Its basic principle is to drive chemical reactions through an electric current, oxidize and decompose organic pollutants in sewage into harmless substances, and achieve the purpose of purifying water quality. Compared with traditional physical or chemical methods, this technology exhibits higher degradation efficiency and a lower risk of secondary pollution, and is particularly suitable for the treatment of high-concentration organic wastewater.

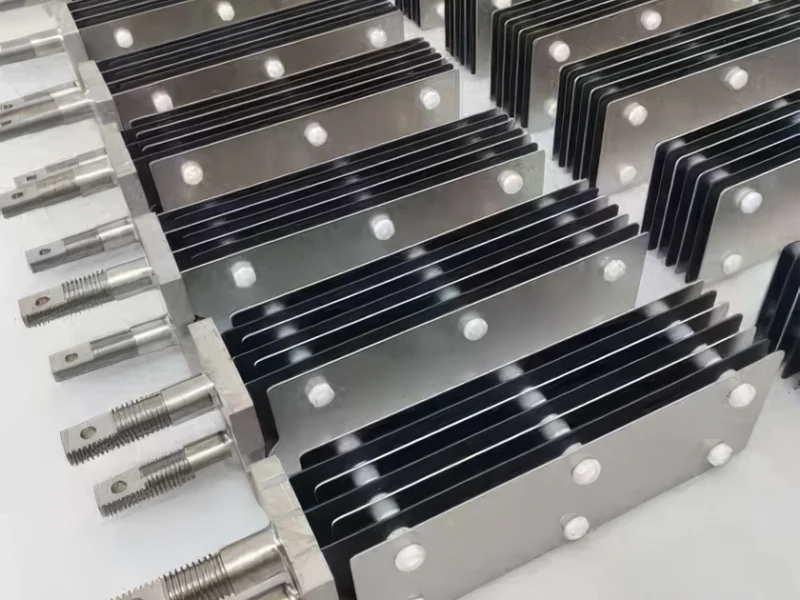

In the electrocatalytic oxidation process, the selection of anode materials is of crucial importance as it directly affects the efficiency, stability, and economic efficiency of the electrocatalytic reaction. Titanium anodes, due to their good electrical conductivity, corrosion resistance, and long service life, have gradually become key materials in electrocatalytic oxidation technology. In addition, titanium anodes can operate at high current densities, which improves the reaction rate and enhances the effectiveness of sewage treatment.

The electrocatalytic oxidation technology has great application potential in sewage treatment. Through reasonable electrode design and adjustment of process parameters, optimal treatment solutions can be achieved for different types of sewage, thus promoting the commercialization process of this technology. Electrocatalytic oxidation can not only effectively remove pollutants in sewage, but also is a promising water treatment technology.

Advantages

Titanium anode for electrocatalytic oxidation of sewage treatment

As a key material for electrocatalytic oxidation of sewage treatment, the titanium anode has several significant advantages, making it the preferred choice in the industry.

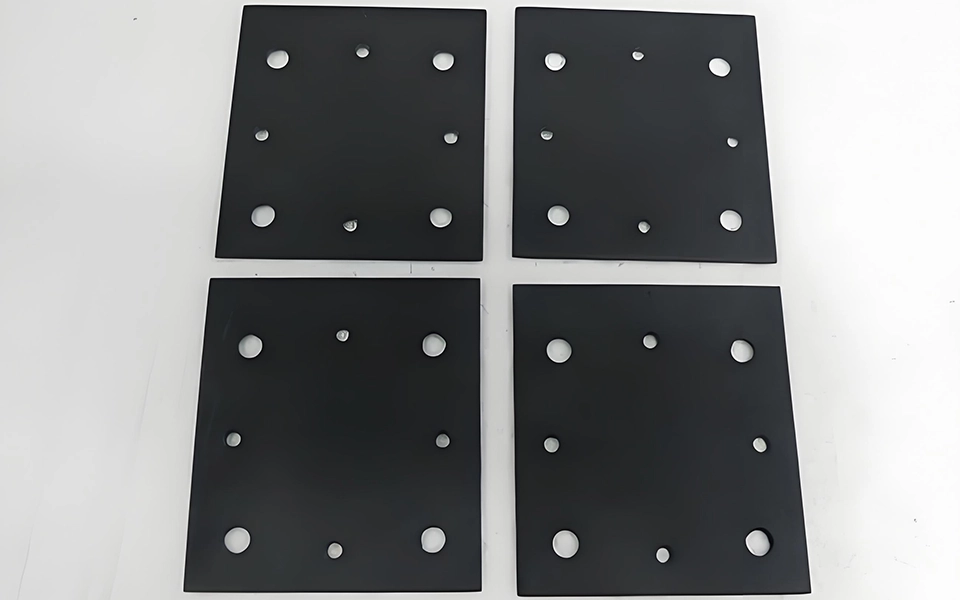

Titanium anodes are electrode materials widely used in electrocatalytic oxidation for sewage treatment. Their physical and chemical properties endow them with unique advantages in the field of water treatment. Firstly, titanium anodes possess excellent corrosion resistance, enabling them to operate continuously in various harsh environments. During the electrocatalytic oxidation of sewage, anodes often face complex water quality and high concentrations of organic pollutants. The corrosion-resistant property of titanium anodes significantly extends their service life and reduces the maintenance frequency and replacement costs.

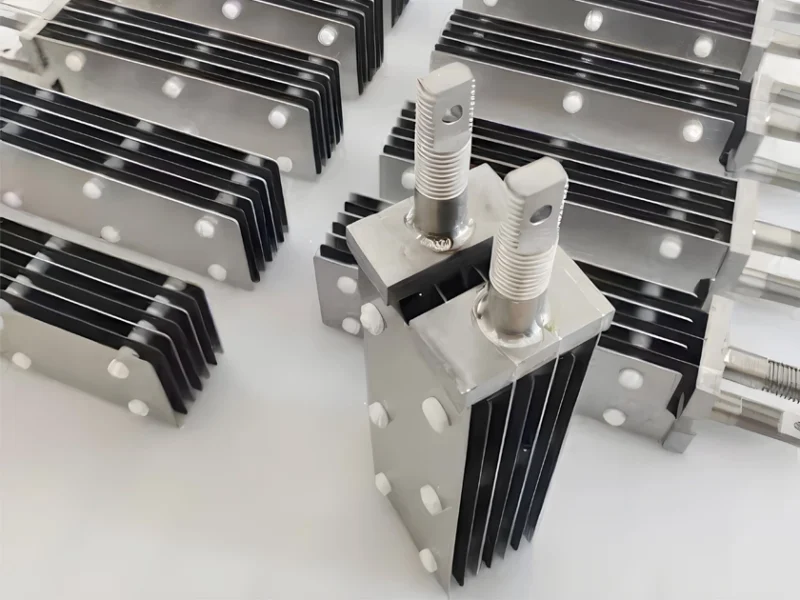

In addition, titanium has good electrical conductivity, which is extremely important in electrocatalytic reactions. Good electrical conductivity means that the titanium anode can effectively conduct electric current, thus improving the reaction efficiency. As the electric current flows, the titanium anode can generate sufficient active substances to accelerate the removal process of pollutants in sewage. In addition, the reaction ability of the titanium anode can be further enhanced by coating noble metal catalysts such as platinum or iridium, making it perform even better when treating specific types of sewage.

In addition to corrosion resistance and electrical conductivity, the mechanical strength of titanium anodes is relatively high. In practical applications, this strength ensures that the anode can withstand the pressure of the generated gas and electrolyte without being easily deformed or damaged, thus maintaining its long-term stability. Combining these characteristics, titanium anodes present an efficient, economical, and sustainable solution in the application of electrocatalytic oxidation of sewage. Therefore, titanium anodes not only perform outstandingly in electrocatalytic reactions but also play a crucial role in promoting the advancement of sewage treatment technology.

Excellent corrosion resistance

Titanium anode can operate continuously in various harsh environments, performing excellently when dealing with complex water quality and high concentrations of organic pollutants, significantly extending their service life and reducing maintenance costs.

Excellent electrical conductivity

Good electrical conductivity ensures that the titanium anode can effectively conduct current, improve the reaction efficiency, and accelerate the removal process of pollutants in sewage. The reaction ability can be further enhanced by coating with noble metal catalysts.

Technical Principle

The working principle of

electrocatalytic oxidation of sewage

Electrocatalytic oxidation of sewage treatment is an advanced technology that uses electrochemical reactions to degrade pollutants. Its basic principle involves redox reactions, which exhibit strong decontamination capabilities when occurring on the electrodes.

During this process, the anode and cathode undertake different reaction tasks respectively: oxidation occurs at the anode, and reduction occurs at the cathode. The current is conducted through the electrodes, causing the transfer of electrons between the electrodes and pollutants, resulting in corresponding changes in the electrode potential.

Selecting appropriate electrode materials such as titanium anodes will significantly improve the efficiency of electrocatalytic reactions. This is because titanium anodes contribute to the generation of reactive oxygen species, thus more effectively degrading organic pollutants in sewage.

Temperature influence

Higher temperatures usually increase the reaction rate, but may reduce the catalyst stability.

Impact of PH value

In an acidic environment, the oxidation efficiency of certain organic substances is high, and alkalinity may accelerate corrosion.

Practical applications

Application scenarios of titanium anode

Efficient removal of chromaticity and organic matter

Experiments show that using a titanium anode to treat printing and dyeing wastewater can effectively remove more than 90% of the color and most of the organic matter. The treatment efficiency can be further improved by optimizing the current density and reaction time.

The processing efficiency is increased by 40%.

The removal effect of ammonia nitrogen is remarkable.

Using a titanium anode coated with ruthenium and iridium to treat urban domestic sewage shows particularly outstanding performance in ammonia nitrogen removal. The ammonia nitrogen concentration can be significantly reduced in a short time, and it has a long service life and obvious economic benefits.

The electrocatalytic oxidation sewage treatment technology combined with titanium anodes not only significantly improves the environmental quality but also brings considerable economic benefits. Through the optimization of the overall treatment system and sustainability analysis, it can help policymakers and investors better understand its potential environmental benefits and economic returns, and regard the promotion of this technology as an important direction in the future water treatment industry.

The market demand for titanium anode sewage treatment systems is gradually increasing. With the acceleration of the industrialization process, the sewage discharge has surged, and traditional sewage treatment technologies can no longer meet the requirements of environmental standards. This has brought huge market opportunities for the electrocatalytic oxidation technology. Titanium anodes exhibit excellent stability and corrosion resistance during the electrocatalytic oxidation process, making them the preferred material in the industry. In addition, the use of titanium anodes can greatly improve the sewage treatment efficiency, shorten the treatment time, and thus reduce the operating costs of enterprises. These advantages have made the electrocatalytic oxidation technology more and more popular in the market.

More and more enterprises are aware of the necessity of investing in sustainable and environmentally friendly technologies. Titanium anodes have demonstrated great potential in optimizing the performance of sewage treatment systems, enabling enterprises to achieve environmental goals while improving production efficiency. Therefore, in addition to traditional markets, many emerging markets have also gradually recognized the electrocatalytic sewage treatment technology. It is predicted that in the next few years, with the increasingly strict environmental regulations and the improvement of public environmental awareness, the application of titanium anode sewage treatment technology will be further expanded, and the market prospects are promising.

The core role of titanium anodes for wastewater treatment

titanium anodes for wastewater treatment,which generates strong oxidizing substances (such as hydroxyl radicals, chlorine gas, etc.) through electrolysis, efficiently degrades organic pollutants, removes heavy metal ions, and achieves sterilization and disinfection at the same time.

Case Study of titanium anodes in Wastewater Treatment

- Printing and dyeing wastewater treatment:The wastewater from the dyeing park has high salt content and excessive chromaticity. After introducing titanium electrode electrochemical equipment, the COD has decreased from 800mg/L to below 50mg/L, and the chromaticity removal rate has reached 95%.The ammonia nitrogen content has dropped to below 0.5mg/L, the COD has decreased from 592mg/L to 37mg/L, and the chromaticity has also been significantly removed.

- Electroplating wastewater treatment:The electroplating industrial park adopts the “chemical precipitation – electrolysis – activated carbon adsorption” process to treat wastewater containing cyanide, chromium, and nickel, with a daily treatment capacity of 3,000 tons. The electrolysis unit uses a titanium-based coated anode, and the current density is controlled at 150A/m². The final effluent has a hexavalent chromium content of <0.1mg/L and a nickel ion concentration of <0.5mg/L, meeting the discharge standards.

- Landfill Leachate Treatment:Waste leachate treatment project with a daily treatment capacity of 50 tons. The raw water has a COD of 1600mg/L and ammonia nitrogen of 2000mg/L. After treatment using an electrochemical system with a titanium-based ternary ruthenium oxide coated anode, the COD is degraded to below 160mg/L, the total nitrogen is reduced to below 60mg/L, and heavy metal ions are also effectively degraded.