Titanium anode for chlorine dioxide generator (MMO anodes/DSA anodes)

Titanium anode for chlorine dioxide generator,The core working principle is to utilize the electrocatalytic activity of the titanium anode to efficiently convert chlorine-containing raw materials into chlorine dioxide under the action of an electric field, while inhibiting side reactions to ensure the purity of the product and the long-term stable operation of the equipment.

Electrochemical Properties of Titanium Anodes for Chlorine Dioxide Generators

Compared with traditional chemical methods, the titanium anode used in the electrolytic chlorine dioxide generator can reduce by-products and improve raw material utilization. When the ruthenium-iridium coating is used in the electrolysis of brine, the active chlorine yield reaches 1000 mg/L, and combined with ion membrane technology, the purity of ClO₂ can be stably maintained above 92%.

Substrate | Gr1/Gr2 |

Coating | RuO₂-IrO₂-TiO₂ |

Electric current | <1000A/m2 |

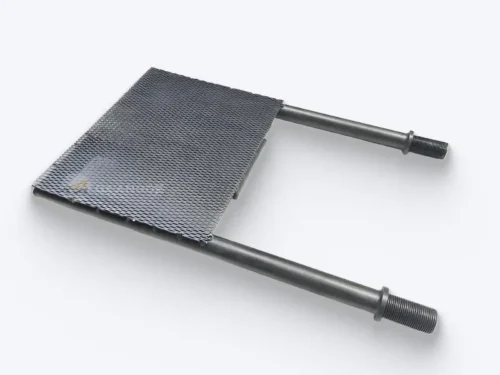

Shape | Titanium plate/Titanium mesh/Titanium tube |

Chlorine dioxide (ClO₂), as a highly efficient and broad-spectrum oxidizing agent and disinfectant, demonstrates significant application value in fields such as drinking water treatment, medical wastewater disinfection, and industrial wastewater purification. The electrolysis method has become the mainstream technology for ClO₂ preparation due to its advantages of high product purity, simple operation, and environmental friendliness, and the performance of anode materials directly determines the electrolysis efficiency and product selectivity. Titanium anode, with their excellent corrosion resistance, mechanical strength, and surface modifiability, have become the core material for ClO₂ preparation by electrolysis.

Reaction mechanism of titanium anode for chlorine dioxide generator

Titanium anode play a core role in the electrolytic preparation of chlorine dioxide, and the electrochemical reactions occurring on their surface are crucial for determining product formation. Chloride ions undergo a multi-step oxidation process on the anode surface, converting into chlorine gas through electrochemical oxidation. This process is influenced by the electron conduction characteristics of the titanium anode surface and the electrolyte environment. The oxide structure formed on the surface of the titanium anode can significantly affect reaction kinetics, and its growth mechanism involves the synergistic effect of oxygen bubble effects and ion migration.

After chlorine gas is generated, it further reacts with water molecules to form chlorine dioxide. This step involves a complex proton-coupled electron transfer process. The PH value of the electrolyte and the concentration of chloride ions have a regulatory effect on the reaction path, and acidic conditions can promote the conversion efficiency of chlorine gas to chlorine dioxide.

Application of Titanium Anodes in the Preparation of Chlorine Dioxide by Electrolysis

Chlorine dioxide, as an efficient and broad-spectrum disinfectant, holds an irreplaceable position in fields such as water treatment, food processing, and medical epidemic prevention. The traditional chemical production of chlorine dioxide has drawbacks such as low raw material utilization, many by-products, and severe environmental pollution, which makes the electrolysis method gradually become a research hotspot due to its characteristics of high selectivity and low pollution. In the process of preparing chlorine dioxide by electrolysis, the selection of anode materials directly determines the reaction efficiency and product purity. Titanium anodes, with their excellent comprehensive performance, have become the core research object in this field. The corrosion resistance of titanium anodes enables them to work stably for a long time in electrolytic environments with strong acidity and high current density, avoiding the problem that traditional metal anodes are prone to passivation or dissolution; their high conductivity ensures electron transmission efficiency and reduces energy consumption; through the surface ruthenium-iridium coating, the selectivity of chlorine dioxide generation can be significantly improved. Studies have shown that when titanium anodes with ruthenium coating are used to prepare chlorine dioxide by electrolyzing brine, the yield of active chlorine (chlorine dioxide) reaches the highest level, with the maximum concentration up to 1074mg/L, which is significantly better than other anode materials.

Reaction Mechanism of Titanium Anode Used in Chlorine Dioxide Generator

Titanium anode for chlorine dioxide generator, the electrochemical reactions occurring on the surface are the key to determining product formation. Chloride ions undergo multiple oxidation processes on the anode surface to be converted into chlorine gas, and this process is affected by the electron conduction properties of the titanium anode surface and the electrolyte environment. The oxide structure formed on the surface of the titanium anode can significantly influence reaction kinetics, and its growth mechanism involves the synergistic effect of oxygen bubble effects and ion migration. As electrolysis proceeds, the titanium substrate continues to undergo oxidation reactions, and a stable titanium oxide layer is gradually formed on the surface. The microstructure of this layer directly determines the adsorption and reaction activity of chloride ions.

After chlorine gas is generated, it further reacts with water molecules to form chlorine dioxide. This step involves a complex proton-coupled electron transfer process. The PH value of the electrolyte and the concentration of chloride ions have a regulatory effect on the reaction path, and acidic conditions can promote the conversion efficiency of chlorine gas to chlorine dioxide. At the same time, the conductivity and corrosion resistance of the titanium anode are crucial to the continuous stability of the reaction.

The regulatory effect of electrolysis condition parameters on the reaction mechanism is equally significant. The current density determines the rate of oxidation reactions on the anode surface; an excessively high current may lead to an increase in local overpotential, triggering competition from side reactions.

Application and Maintenance of Titanium Anodes for Chlorine Dioxide Generators

- Adaptation to electrolytic preparation scenarios

Chlorine dioxide generators mostly use the electrolysis method for preparation. Titanium anodes are often used as anode substrates, with their surfaces coated with precious metal oxide coatings such as ruthenium-iridium and ruthenium-titanium.

This coating can reduce the oxygen evolution potential, improve the conversion efficiency of chloride ions to chlorine dioxide, and at the same time prevent the titanium substrate itself from being corroded. - Advantages Manifestation

It has strong electrical conductivity, resulting in lower energy consumption during the electrolysis process, which meets the energy-saving requirements of environmental protection equipment.

Resistant to acid and alkali corrosion, suitable for the acidic electrolyte environment inside the generator.

The size and shape of the electrode plates can be customized to fit the cavity design of generators with different specifications. - Typical application fields

It is widely used in scenarios such as disinfection of water supply plants, treatment of industrial wastewater, and disinfection of hospital sewage, and is particularly suitable for treating complex water quality containing both ammonia nitrogen and organic substances.

Daily maintenance of titanium anodes

- Regular cleaning

During the electrolysis process, oxide or scale deposits form on the surface of the anode, leading to passivation.

It is recommended to immerse the plates in a 5%-10% dilute hydrochloric acid solution for 30-60 minutes every 1-2 months. After removing the surface contaminants, rinse them thoroughly with clean water. - Control the electrolysis operating conditions

Strictly control the pH value of the electrolyte to prevent the alkaline environment from accelerating the peeling of the coating.

Control the current density within the designed range; an excessively high current density will cause local overheating and damage the coating structure. - Shutdown maintenance

When the equipment is out of service for a long time, the anode should be removed from the generator, cleaned and stored dry.

Avoid leaving the titanium anode in the electrolyte for a long time to prevent the coating from undergoing chemical dissolution.

Manufacturer of titanium anode

Qixin Titanium is a manufacturer of titanium anodes from China., focusing on the R&D, manufacturing and application of MMO coated titanium anodes.

Qi Xin Titanium was founded in 2006., with over 20 years of manufacturing experience, we provide stable and reliable titanium anode products suitable for multiple scenarios. We help enterprises improve electrolysis efficiency, reduce operating costs, and offer personalized customization to ensure long-term stable operation.