Titanium anode for aluminum foil formation

Titanium anodes play a crucial role in the aluminum foil formation process for electrolytic capacitor production, directly impacting product performance and production efficiency.

In the modern electronics industry, electrolytic capacitors, as indispensable electronic components, are widely used in consumer electronics, automotive electronics, industrial control, aerospace, and many other fields. From portable electronic devices such as smartphones and tablets to battery management systems in new energy vehicles, and power conversion and control in industrial automation, electrolytic capacitors play a key role in storing and releasing electrical energy. Their performance directly affects the stability, reliability, and service life of electronic devices.

Aluminum foil formation, as a key process in the production of electrolytic capacitors, plays a decisive role in capacitor performance. During the aluminum foil formation process, a high-quality aluminum oxide dielectric film is formed on the surface of high-purity aluminum foil through specific electrochemical treatment. This aluminum oxide film is not only the core for capacitors to achieve charge storage and isolation but also its quality and performance directly determine key parameters such as capacitance value, leakage current, and dissipation factor of capacitors.

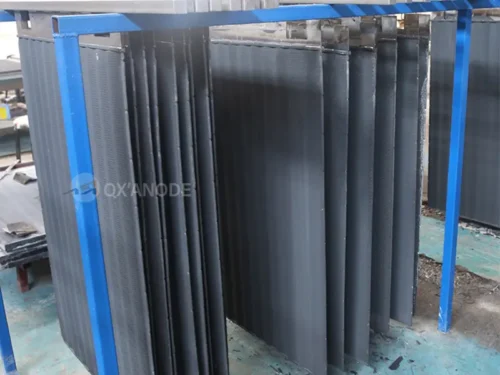

Titanium anodes play a vital role in the aluminum foil formation process and have an irreplaceable effect on improving the quality and efficiency of aluminum foil formation. Titanium anodes have excellent corrosion resistance, enabling them to work stably for a long time in complex electrolyte environments, effectively extending the service life of electrodes and reducing production costs. Their good conductivity ensures uniform current distribution in the electrolyte, providing a stable electric field environment for aluminum foil formation, which helps form a uniform and dense aluminum oxide film, thereby improving the quality of aluminum foil formation.

High Performance

Titanium anodes provide a stable electric field environment, helping to form high-quality aluminum oxide films and improve capacitor performance.

Long Service Life

Excellent corrosion resistance ensures titanium anodes work stably for a long time in complex electrolyte environments, reducing replacement frequency.

High Efficiency

High oxygen evolution overpotential characteristics reduce side reactions, improve current efficiency, reduce energy consumption, and enhance production efficiency.

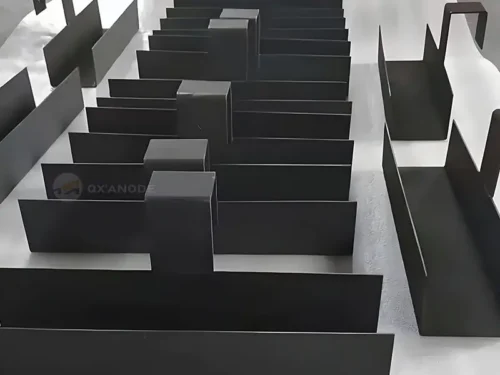

Overview of Titanium Anodes for Aluminum Foil Formation

Basic Concepts of Titanium Anodes

Titanium anodes, full name titanium-based metal oxide coated electrodes (MMO), are also known as dimensionally stable anodes (DSA). They use titanium as the base material and coat a layer of metal oxide with electrocatalytic activity on its surface through specific processes. This unique structural design endows titanium anodes with many excellent properties, making them play a key role in many electrochemical fields.

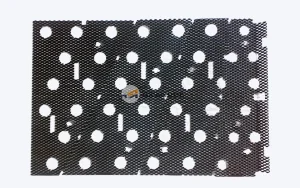

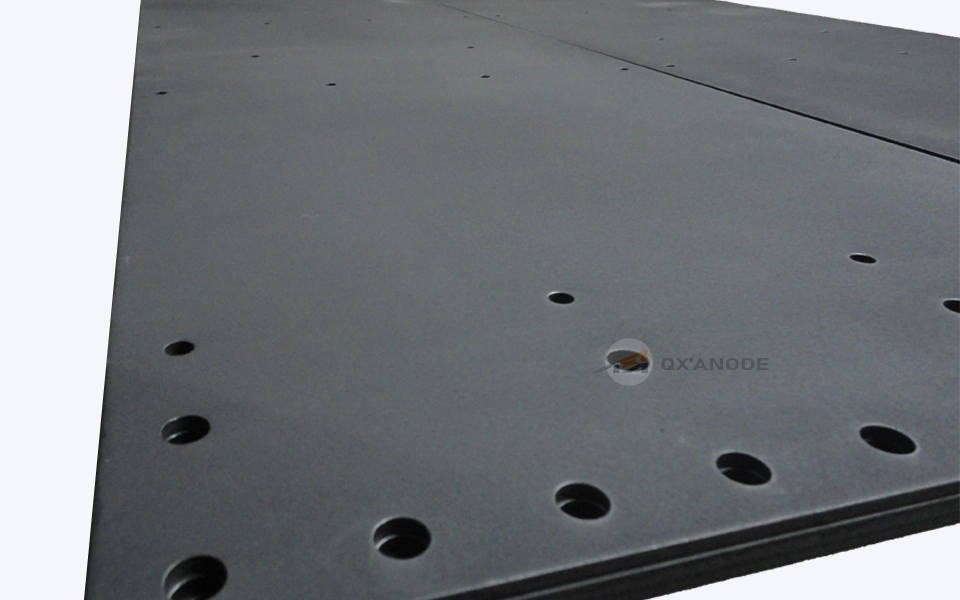

Structural Composition of Titanium Anodes

- Titanium Substrate: Provides mechanical support and conductivity, with characteristics of low density, high strength, and strong corrosion resistance

- Metal Oxide Coating: Determines the electrocatalytic performance of the electrode, usually composed of precious metal oxides

In the aluminum foil formation process, the working principle of titanium anodes is based on electrochemical oxidation reactions. When an external DC power supply is connected, current flows from the positive pole of the power supply into the titanium anode, and electrons flow from the surface of the titanium anode into the electrolyte. On the anode surface, the metal oxide coating acts as a catalyst, promoting the oxidation reaction of anions (such as hydroxide ions OH⁻) in the electrolyte to generate oxygen (O₂) and release electrons. These electrons return to the negative pole of the power supply through the external circuit, forming a complete current loop.

Characteristics of Titanium Anodes

Iridium-Coated Titanium Anodes

Iridium-coated titanium anodes are a type of titanium anode with iridium and its oxides coated on the surface of a titanium substrate. Iridium is a precious metal with high chemical stability and excellent electrocatalytic performance, and its coating endows titanium anodes with unique performance advantages.

Performance Characteristics

- Excellent corrosion resistance, suitable for strong acidic and strong oxidizing environments

- Low oxygen evolution overpotential, reducing energy consumption in the electrolysis process

- Good conductivity and stability, ensuring uniform current distribution

Preparation Process

Mainly using the thermal decomposition method:

- Coating a solution containing iridium salts on the surface of the titanium substrate

- High-temperature heat treatment to decompose the iridium salts

- Forming an iridium oxide coating on the titanium substrate

In terms of application effects in aluminum foil formation, iridium-coated titanium anodes perform excellently. Due to their excellent corrosion resistance and low oxygen evolution overpotential, they can operate stably under high current densities, thereby improving the production efficiency of aluminum foil formation. At the same time, their good electrocatalytic performance and uniform current distribution help form high-quality aluminum oxide films on the aluminum foil surface.

Principle of Aluminum Foil Formation and Mechanism of Titanium Anode Action

Basic Principle of Aluminum Foil Formation

Aluminum foil formation is a complex process based on electrochemical principles. Its core is to apply a DC voltage to high-purity aluminum foil in a specific electrolyte environment, causing it to undergo anodic oxidation reaction, thereby forming a high-quality aluminum oxide film on the surface of the aluminum foil. This aluminum oxide film has good insulation and stability and is a key component for electrolytic capacitors to achieve charge storage and isolation.

Main Chemical Reaction Equations

Oxidation Reaction of Aluminum

2Al – 6e⁻ → 2Al³⁺

Oxidation Reaction of Hydroxide Ions

4OH⁻ – 4e⁻ → O₂ ↑ + 2H₂O

Aluminum Foil Formation Process

- Anions in the electrolyte migrate to the anode (aluminum foil) surface

- Aluminum atoms lose electrons and are oxidized to aluminum ions Al³⁺

- Hydroxide ions are oxidized to generate oxygen and water

- Aluminum ions combine with oxygen atoms to form aluminum oxide Al₂O₃

- Aluminum oxide continuously deposits and grows, forming a continuous and dense oxide film

Mechanism of Titanium Anode Action in Aluminum Foil Formation

In the aluminum foil formation process, titanium anodes play a crucial role, and their mechanism of action is mainly reflected in providing a stable oxidation environment, promoting the formation of aluminum oxide layers, and multiple impacts on the quality of aluminum foil formation.

Stable Oxidation Environment

Provides a stable electric field environment, ensures uniform current distribution, avoids abnormal local current density, and creates conditions for the uniform growth of aluminum oxide films.

Promoting Oxide Layer Formation

The metal oxide coating provides a catalytic effect, reduces the activation energy of the oxygen evolution reaction, accelerates the generation of reactive oxygen species, and promotes the formation of aluminum oxide films.

Improving Formation Quality

Improves the density and uniformity of aluminum oxide films, reduces porosity, improves capacitor performance, and at the same time increases production efficiency and reduces energy consumption.

Impact of Titanium Anodes on Aluminum Foil Formation Quality

AFFECTED ASPECT | SPECIFIC IMPACT | EFFECT |

Aluminum Oxide Film Structure | Promotes the formation of a denser microstructure and reduces porosity | Improves insulation performance and reduces leakage current |

Stability and Service Life | Excellent corrosion resistance, reduces electrode replacement frequency | Ensures production continuity and reduces maintenance costs |

Current Efficiency | Reduces energy loss from side reactions and improves electrical energy utilization | Improves production efficiency and reduces energy consumption per unit product |

Performance Research of Titanium Anodes for Aluminum Foil Formation

Electrochemical Performance

- Oxygen Evolution Potential

Oxygen evolution potential is one of the important indicators to measure the electrochemical performance of titanium anodes and has a significant impact on aluminum foil formation efficiency. During the aluminum foil formation process, the oxidation reaction of water occurs on the anode surface to generate oxygen, and the oxygen evolution potential determines the difficulty of this reaction.

The iridium oxide coating on the surface of iridium-coated titanium anodes can effectively reduce the activation energy of the water oxidation reaction, making the reaction easier to proceed along a low-energy path, thereby reducing the oxygen evolution potential. A lower oxygen evolution potential can increase the rate of the anode reaction and reduce energy consumption during the electrolysis process.

- Current Efficiency

Current efficiency is a key parameter to measure the electrical energy utilization efficiency of titanium anodes in the aluminum foil formation process, which reflects the ratio of the electricity quantity actually participating in the aluminum foil oxidation reaction to the total electricity quantity passing through the electrode.

With the increase of current density, the current efficiency of titanium anodes first increases and then decreases. Within a certain range, as the electrolyte temperature increases, the current efficiency gradually increases, but begins to decrease after exceeding a specific temperature.

- Electrode Potential Stability

The stability of the titanium anode electrode potential is one of the key factors to ensure the stable progress of the aluminum foil formation process, which is directly related to the consistency of the quality and performance of the aluminum oxide film. During the aluminum foil formation process, fluctuations in electrode potential may lead to unstable reaction rates on the anode surface, thereby affecting the growth uniformity and density of the aluminum oxide film.

Corrosion Resistance Performance

Electrolyte Corrosion

During the aluminum foil formation process, titanium anodes need to be immersed in corrosive electrolytes for a long time, so their corrosion resistance is directly related to the service life of the electrodes and the stability of aluminum foil formation. Different electrolyte systems have different corrosion effects on titanium anodes.

ELECTROLYTE SYSTEM | CORROSION CHARACTERISTICS | CORROSION MECHANISM |

|---|---|---|

Ammonium Adipate System | Weakly acidic environment, moderate corrosion | Hydrogen ions react with the metal oxide coating, causing coating dissolution and further corrosion of the titanium substrate |

Boric Acid System | Relatively mild, low corrosion | Borate ions may form complex reactions with metal oxides, weakening coating adhesion |

Oxide Film Stability

The oxide film on the surface of titanium anodes plays a crucial role in their corrosion resistance. It is a key barrier to prevent further corrosion of the titanium substrate by the electrolyte. The stability of the oxide film directly affects the service life and performance of titanium anodes in the aluminum foil formation process.

Factors for Oxide Film Formation and Destruction

Formation Factors

- Reaction between titanium and dissolved oxygen in the electrolyte

- Reaction with oxidizing substances in the electrolyte

- Formation of a dense titanium dioxide (TiO₂) oxide film

Destruction Factors

- Dissolving effect of hydrogen ions in acidic electrolytes

- Further oxidation by strong oxidizing substances

- Mechanical damage (bubble impact, friction, etc.)