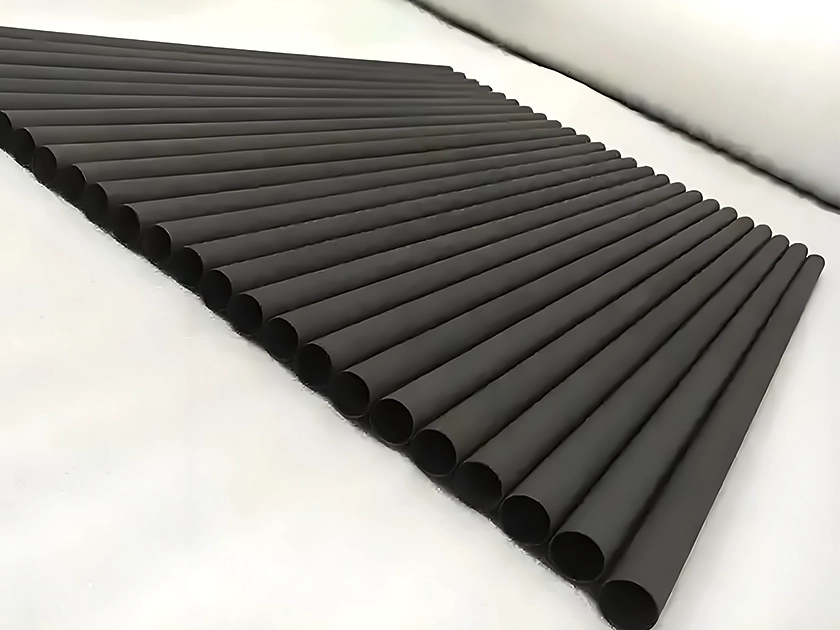

MMO anodes for cathodic protection

The Anti Corrosion Performance of Titanium Anodes for Cathodic Protection

Importance of Cathodic Protection

Cathodic protection (CP) is a method employed to prevent the corrosion of metals that are exposed to various environments, especially those susceptible to aggressive elements such as seawater or moist soil. This technique is crucial for various structures, including pipelines, ships, and offshore platforms, where the risk of corrosion can lead to significant operational issues and maintenance costs. The fundamental principle behind cathodic protection is based on electrochemistry, where the metal structure to be protected is made the cathode of an electrochemical cell. This process inhibits the oxidation reaction, thereby minimizing metal deterioration.

In a cathodic protection system, two common technologies are utilized: sacrificial anodes and impressed current systems. Sacrificial anodes, typically composed of metals such as zinc, magnesium, or aluminum, are designed to corrode preferentially. As these anodes corrode, they provide protection to the primary metal structure. In contrast, impressed current systems employ an external power source to supply a constant supply of current, passing it through inert anodes to achieve protection. The choice of system depends on factors such as the environment and the type of structure being protected.

Among the various materials used for anodes, titanium has garnered attention for its excellent anti-corrosion properties. Titanium anodes offer several advantages, including longer service life, higher efficiency, and reduced maintenance needs compared to traditional materials. Their impressive resistance to galvanic corrosion and ability to withstand harsh environments make them suitable for numerous applications in cathodic protection systems. Understanding how cathodic protection works and the role of titanium anodes is essential for anyone involved in the design and maintenance of metal structures, as effective corrosion prevention is critical to extending the life of these assets and minimizing long-term costs.

Titanium Anodes: Properties and Advantages

Titanium has emerged as a remarkable material for anodes in cathodic protection systems, primarily due to its unique properties. One of the standout features of titanium is its impressive strength-to-weight ratio, which allows for lightweight construction while maintaining exceptional durability. This characteristic is particularly advantageous in applications where reducing weight is crucial, such as in marine and aerospace environments.

Another significant property of titanium is its unparalleled resistance to corrosion. When exposed to harsh conditions, such as saltwater or acidic environments, titanium forms a protective oxide layer that significantly enhances its durability. This exceptional corrosion resistance leads to a longer lifespan for titanium anodes compared to traditional materials like zinc and magnesium, which are more prone to degradation. Consequently, the longevity of titanium anodes translates not only to cost-effective maintenance but also to improved performance in cathodic protection systems.

In addition to strength and corrosion resistance, titanium demonstrates remarkable biocompatibility, making it suitable for various applications across different industries, including biomedical and marine sectors. This property ensures that titanium anodes do not leach harmful substances into the environment, thereby offering an environmentally friendly alternative to other anode materials. Furthermore, the efficiency of titanium anodes in cathodic protection systems is noteworthy. Their ability to provide consistent electrochemical performance contributes to the effectiveness of mitigating corrosion in metal structures, leading to enhanced operational reliability.

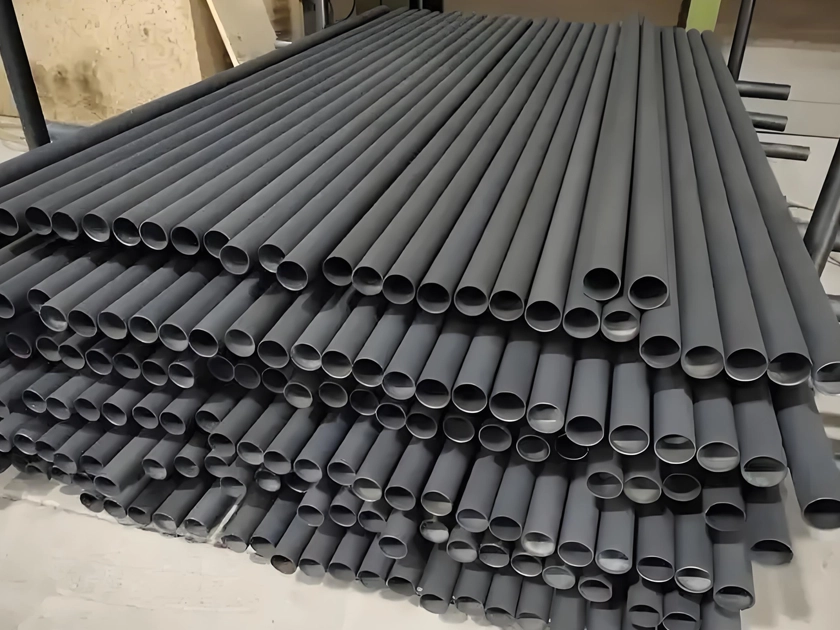

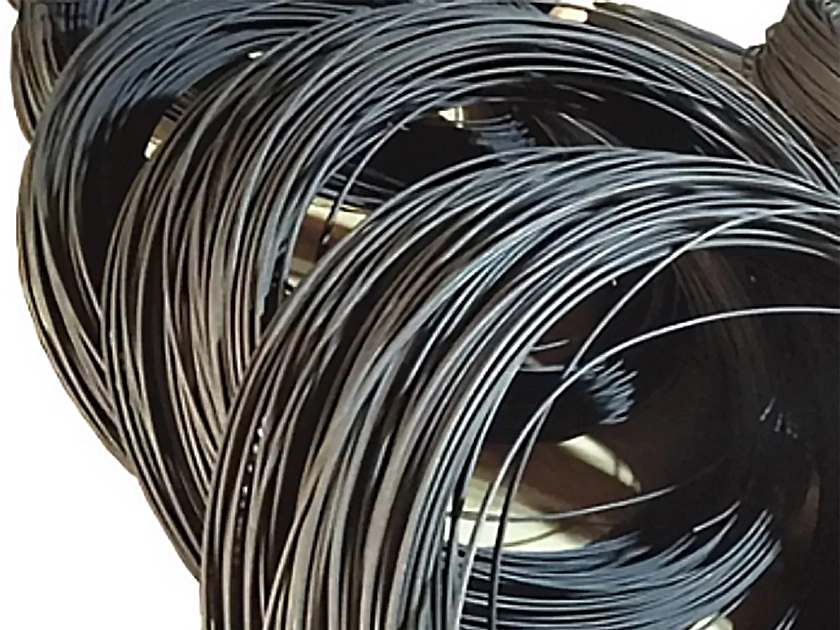

MMO (Mixed Metal Oxide) anodes are a specialized category of anodes utilized in cathodic protection systems to mitigate corrosion. These anodes are composed of a titanium substrate coated with a mixed metal oxide layer, which primarily includes noble metals such as iridium, ruthenium, and titanium oxides.

One of the key differentiators of MMO anodes is their low consumption rate, which translates into prolonged service life. Unlike traditional anodes that rely on sacrificial methods, MMO anodes function through the application of an external electrical current, preventing corrosion processes on the protected metal surfaces.

MMO Anode Composition

- Titanium substrate (base material)

- Iridium oxide (enhances stability)

- Ruthenium oxide (improves conductivity)

- Titanium oxide (increases durability)

- Other proprietary metal oxides

The Working Principle of MMO Anodes

Mixed Metal Oxide (MMO) anodes operate based on established electrochemical principles that are essential for effective cathodic protection. Their primary role is to serve as a component that enhances the corrosion resistance of metallic structures when exposed to electrolytic environments.

During operation, the MMO anode undergoes an anodic reaction, where electrons are released into the electrolyte, facilitating cathodic polarization of the adjacent metal surface. This electron flow counteracts the natural tendency of metals to corrode when in contact with aggressive environments.

The mixed metal oxides serve to lower the overpotential of the anodic process, making the electrochemical reaction more efficient. As a result, MMO anodes can maintain a stable output, providing sufficient protection to the structures they are installed on.

Application of MMO Anodes for Cathodic Protection

Marine Environments

Extensively utilized on ship hulls and offshore structures to safeguard against the detrimental effects of seawater corrosion, maintaining structural integrity and reducing maintenance costs.

Pipelines

Used to shield both onshore and offshore pipelines from corrosive elements, preventing leaks that could lead to significant environmental damage and economic loss.

Storage Tanks

Provide effective corrosion resistance for metal storage tanks containing corrosive substances, extending their longevity and ensuring regulatory compliance.

Offshore Platforms

Maintain structural integrity in offshore oil and gas platforms exposed to harsh marine conditions, reducing the risk of catastrophic failures and ensuring safety.