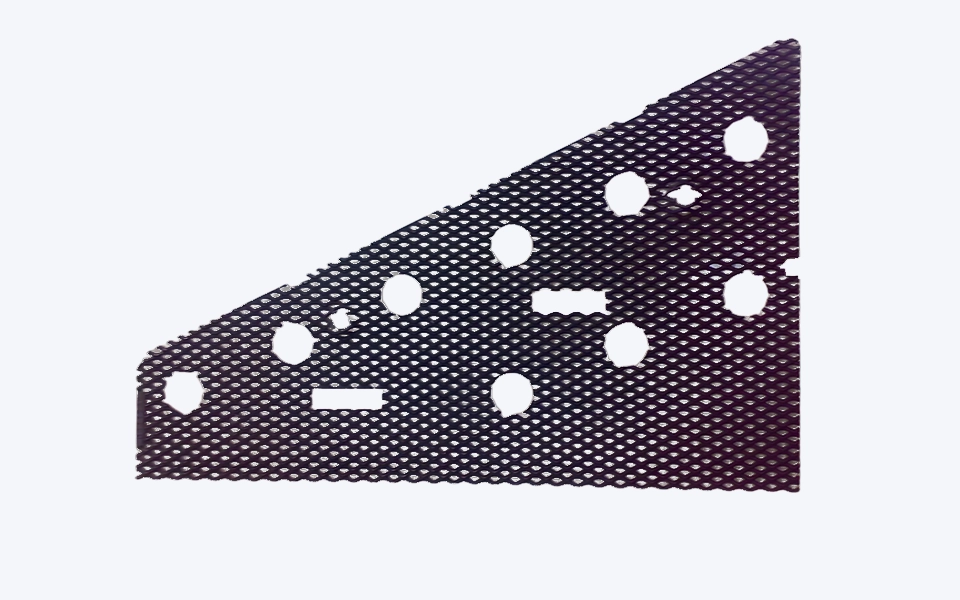

Iridium coated titanium anode

High performance electrochemical solutions

Combined with multi-component composite coating technology, it provides excellent electrochemical performance and adaptability to extreme environments, bringing revolutionary breakthroughs to industrial electrolysis, marine engineering and new energy fields.

Core Advantages

Iridium coated titanium anode, with their unique material design and performance advantages, have become key materials in the modern electrochemical industry. They offer irreplaceable value in terms of improving efficiency, reducing energy consumption, and adapting to harsh environments.

High Efficiency

The extremely low oxygen evolution overpotential (≤1.45V vs SHE), combined with a current efficiency of over 95%, results in significantly reduced energy consumption and improved production efficiency.

Ultra durable performance

In acidic and neutral electrolytes, the lifespan of these anodes can range from 2 to 3 years. Their resistance to pitting corrosion is more than three times greater than that of pure titanium anodes, significantly reducing the frequency of replacements.

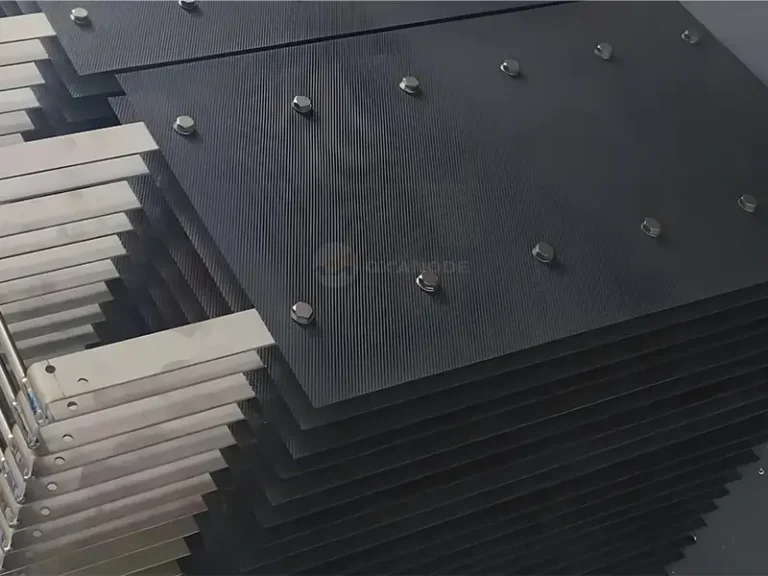

Iridium coated titanium anode, as a high performance electrochemical anode material, plays a pivotal role in the electrolysis industry. By optimizing the treatment of titanium substrates, the proportioning of precious metal coating materials, and the process parameters for coating preparation, an iridium tantalum titanium anode mesh with excellent performance has been developed.

In terms of electrochemical properties, the iridium tantalum titanium anode mesh exhibits a high oxygen evolution potential and low polarization resistance, significantly enhancing electrolysis efficiency. In terms of corrosion resistance, it can maintain stable performance for a long time in various strongly corrosive media. In terms of stability, it can maintain excellent performance under high current density and long-term operation conditions, effectively extending the service life of the anode.

Furthermore, compared with other anode materials, the iridium-tantalum-titanium anode mesh has been widely applied in fields such as PCB horizontal copper plating, the electroplating industry, water electrolysis for hydrogen production, and high-concentration organic wastewater treatment.

Product Features

The synergistic advantages of multi component composite coatings

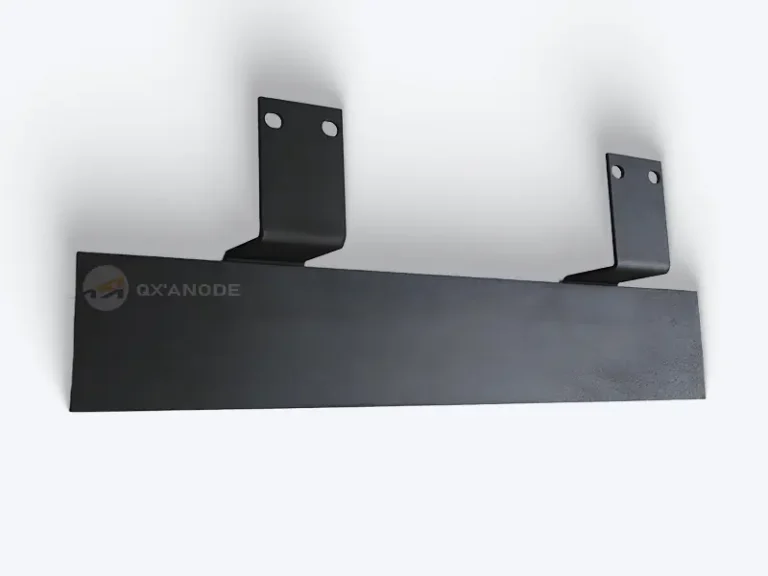

Iridium coated titanium anode utilize a titanium substrate as their base, with a surface coating composed of a composite of iridium (Ir) and tantalum (Ta) oxides, such as IrO₂-Ta2O5. The titanium substrate provides the anode with light weight, high strength, and excellent machinability, while the iridium-tantalum oxide coating achieves an optimal balance between electrochemical activity and stability through its nanostructured design.

The iridium in the coating provides efficient sites for oxygen evolution catalysis, while the tantalum enhances the coating’s resistance to corrosion, protecting the substrate from the erosion caused by strong corrosive agents such as chloride ions. This results in a dual-functional layer that serves both catalytic and protective purposes.

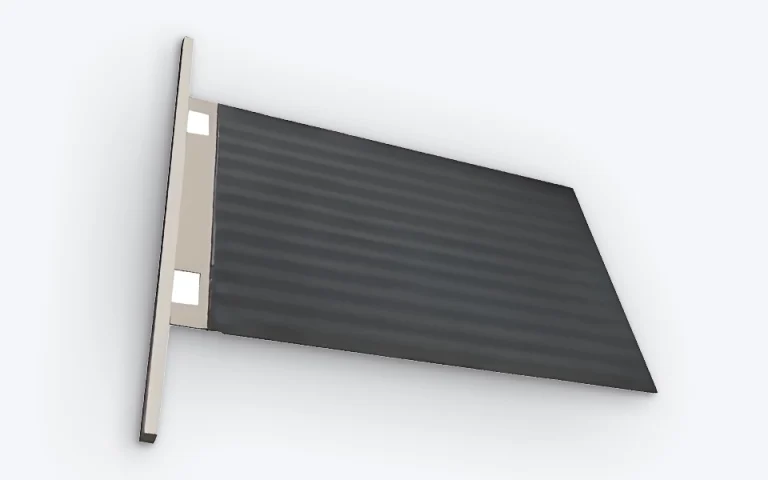

Excellent electrochemical performance

This anode exhibits an extremely low oxygen evolution overpotential (≤1.45V vs SHE) and demonstrates high current efficiency (70~90%) in the oxygen evolution reaction, which can significantly reduce energy consumption.

The high electrical conductivity of its surface coating ensures the rapid transfer of electric charges. Additionally, its optimized structural design effectively expands the reactive active area and enhances the catalytic capability per unit area.

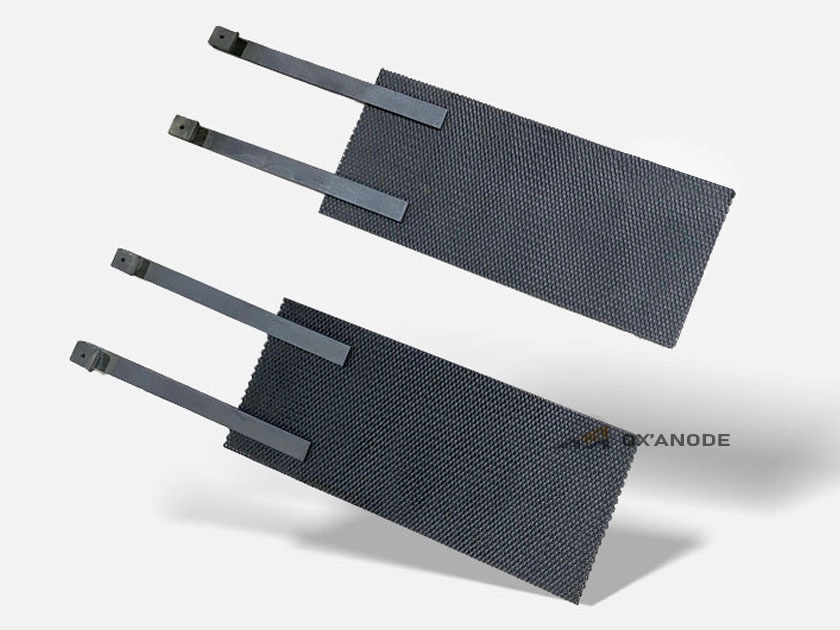

TheIridium coated titanium anode, as a high-performance electrochemical anode material, demonstrates broad application prospects and irreplaceable importance in the field of electrolysis industry. This material is mainly composed of three elements: iridium, tantalum, and titanium. The unique combination of these elements endows the iridium-tantalum-titanium anode mesh with excellent physicochemical properties, especially its outstanding corrosion resistance and electrocatalytic activity.

The corrosion resistance of iridium-tantalum-titanium anode mesh benefits from the chemical stability of its constituent elements. In high current density and strongly corrosive media, the anode mesh can work stably for a long time, which significantly prolongs the service life of the anode. At the same time, its electrocatalytic activity greatly improves the electrolysis efficiency, thereby reducing energy consumption. The combination of these two characteristics makes the iridium-tantalum-titanium anode mesh an ideal choice in the electrolysis industry.

In the production process of electrolytic copper foil, the iridium-tantalum-titanium anode mesh can withstand the impact of high current density and the erosion of corrosive electrolytes, ensuring the stability and efficiency of the production process. In the chlor-alkali industry, the anode mesh also performs excellently. Its corrosion resistance and electrocatalytic activity have significantly improved the production efficiency and quality of chlorine gas. In addition, the iridium-tantalum-titanium anode mesh also plays an indispensable role in the PCB electroplating industry and the field of water electrolysis for hydrogen production.

The iridium tantalum titanium anode demonstrates good electrocatalytic activity. During the electrolysis process, the iridium tantalum titanium anode mesh can effectively reduce the activation energy of the reaction and improve the electrolysis efficiency. This means that under the same current density, using the iridium tantalum titanium anode mesh can more quickly promote the progress of the electrolysis reaction, thereby saving energy consumption. In addition, its high electrocatalytic activity also makes the iridium-tantalum-titanium anode mesh have better effects when treating complex or difficult-to-electrolyze substances.

In addition to corrosion resistance and electrocatalytic activity, the iridium tantalum titanium anode also has the characteristics of high stability and long service life. When working at high current densities, the iridium tantalum titanium anode mesh can maintain stable performance and is not prone to performance degradation or failure. This high stability makes the iridium tantalum titanium anode mesh perform excellently in high intensity and high-load electrolysis tasks, significantly improving production efficiency and product quality. At the same time, its long service life also reduces the need for frequent replacement of the anode mesh, further reducing operating costs.