F.A.Q

Frequently Asked Questions

GENERAL QUESTIONS

Frequently asked questions

The core of the classification of titanium anode lies in the adaptability between the coating material and the application scenario. When making a selection, comprehensive considerations should be given to factors such as the composition of the electrolyte (such as acidity, alkalinity, and chloride ion content), the type of electrolytic reaction (chlorine evolution, oxygen evolution, or others), and the requirements for service life.

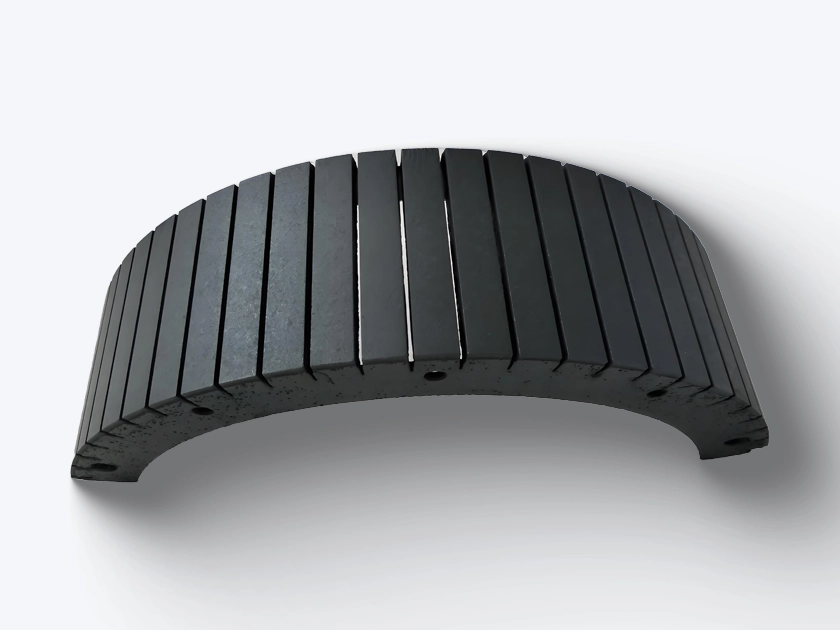

Plate type titanium anode

Form: Flat plate shape, simple structure, large surface area, suitable for large-area electrolytic cells.

Application: Chlor-alkali industry, large-scale electrolytic devices in wastewater treatment.

Mesh type titanium anode

Features: Mesh structure, improves electrolyte flow and electrode surface area, reduces resistance.

Application: Electroplating tanks, fluidized bed electrolytic devices in wastewater treatment.

Tube type titanium anode

Structure: Tubular design, suitable for cylindrical electrolytic cells or scenarios requiring electrolysis with inner holes (such as inner wall treatment of pipes).

Mixed Metal Oxides (MMO) refer to compounds formed by the combination of two or more metal elements with oxygen. They possess unique physical, chemical properties and structural characteristics, and are widely used in various fields.

Ruthenium Iridium Coating is a metal oxide coating with ruthenium (Ru) and iridium (Ir) as the main active components, which is often loaded on metal substrates such as titanium (Ti). Titanium as the substrate provides good mechanical strength and toughness for the anode. Ruthenium and iridium oxides are the active components of the anode. Ruthenium can enhance the electrocatalytic activity of the material, and iridium can enhance the stability and corrosion resistance of the material. By adjusting the ratio of ruthenium and iridium, the electrochemical properties of the material can be precisely adjusted to adapt to different application scenarios.

In a strongly acidic and high chloride ion concentration electrolysis environment (such as the electrolysis of saturated brine), the coating is not easily corroded and its service life can reach more than 3 years.

With the balance of “catalytic activity – corrosion resistance – stability”, the ruthenium-iridium coating has become an irreplaceable functional material in the electrochemical field. With the development of the new energy and environmental protection industries, its application scenarios are still expanding.

During the electrolysis process, the iridium tantalum titanium anodes, as the provider of electrons, participates in the electrochemical reaction. Taking the electrodeposition extraction of non-ferrous metals as an example, the metal ions to be extracted in the electrolyte that has undergone leaching and purification are reduced at the cathode to obtain pure metal. Meanwhile, the iridium-tantalum-titanium anode undergoes an oxidation reaction at the anode. Precious metals such as iridium and tantalum in its coating play an electrocatalytic role, reducing the overpotential and cell voltage of the anodic reaction, enabling the reaction to proceed efficiently with low energy consumption.

Classification by Coating Material

DSA (Dimensionally Stable Anode) Type Titanium Anode

Definition: A dimensionally stable anode, typically using titanium as the substrate and coated with oxides of metals such as ruthenium (Ru), iridium (Ir), and titanium (Ti) (e.g., RuO₂, IrO₂).

Characteristics:

Strong corrosion resistance and high stability in acidic, chloride, and other media.

Low chlorine evolution overpotential, suitable for scenarios such as electrolytic chlorine production and brine electrolysis.

Common Types:

Ruthenium-based coating: With RuO₂ as the main component, commonly used in chlor-alkali industry and chlorine evolution reactions in wastewater treatment.

Iridium-based coating: With IrO₂ as the main component, exhibiting stronger oxidation resistance and suitable for oxygen evolution reactions (e.g., water electrolysis for oxygen production and electroplating solution treatment).

Platinum-Coated Titanium Anode

Characteristics: Platinum (Pt) layer is electroplated or sprayed onto the titanium substrate, featuring extremely high catalytic activity and excellent corrosion resistance.

Applications: Mainly used in high-end electrolysis scenarios, such as fuel cells, precious metal electroplating (e.g., platinum plating), and high-purity water electrolysis.

Mixed Metal Oxide-Coated Titanium Anode

Composition: The coating contains multiple metal oxides (e.g., RuO₂+TiO₂, IrO₂+Ta₂O₅, etc.), with optimized performance through proportioning.

The coating composition can be adjusted according to requirements to balance corrosion resistance, electrical conductivity, and catalytic activity, making it suitable for complex media (e.g., acid-containing and chlorine-containing wastewater treatment).

Classification by Electrochemical Behavior

Chlorine – evolving Titanium Anode

Reaction: During the electrolysis process, chlorine gas (Cl₂) is mainly evolved, and the coating is mainly ruthenium – based.

Scenarios: Chlor – alkali industry, production of chlorine – containing disinfectants.

Oxygen – evolving Titanium Anode

Reaction: Oxygen gas (O₂) is mainly evolved, and the coating is mainly iridium – based or iridium – tantalum mixed coating.

Acid-base property:

Acidic medium (such as sulfuric acid, hydrochloric acid): Preferentially select iridium-based (IrO₂) or mixed oxide coatings (such as IrO₂ + Ta₂O₅), avoiding ruthenium-based coatings from dissolving under strong oxidizing conditions.

Neutral or alkaline medium: Ruthenium-based (RuO₂) coatings offer better cost performance and are suitable for chlor-alkali industry and chlorinated wastewater treatment.

Chloride ion (Cl⁻) content:

High Cl⁻ concentration (such as seawater, saltwater electrolysis): Select ruthenium-based coatings, which have a low chlorine evolution overpotential and are suitable for chlorine evolution reactions (such as chlor-alkali industry, seawater electrolysis for chlorine production).

Low Cl⁻ or Cl⁻ free systems: Select iridium-based or mixed coatings to avoid oxidation loss of ruthenium-based coatings when Cl⁻ is insufficient.

Impurities and corrosive substances:

Containing heavy metal ions (such as Cu²⁺, Ni²⁺) or organic matter: Coatings with anti-pollution capabilities are required. Mixed oxide coatings (such as RuO₂ + TiO₂) can balance corrosion resistance and catalytic activity.