Performance and Application of Coated Titanium Electrodes

With the continuous growth of global energy demand and the increasing awareness of environmental protection, the electrolysis industry is in urgent need of achieving low-carbon transformation through technological innovation. Coated titanium electrodes, with their excellent corrosion resistance and catalytic activity, have become a research hotspot for core materials in electrolytic cells.

Titanium electrodes with a composite coating of ruthenium-iridium oxide can reduce the chlorine evolution potential to 1.14 V (vs. SCE) in chlor-alkali electrolysis, and the current efficiency remains above 95.2% after 1000 hours of continuous operation in a 32% NaOH solution. By introducing a gradient coating design, the conductivity of the electrode is increased by 25%, while the corrosion current density is reduced to 0.8 μA/cm². The corrosion resistance in a 3.5% NaCl solution is two orders of magnitude higher than that of traditional titanium materials.

In the verification of application effects, coated titanium electrodes have shown significant advantages in the chlor-alkali industry and water treatment fields. Industrial cases have demonstrated that titanium anodes with optimized coatings can reduce the DC power consumption per cell by 8% and extend the equipment maintenance cycle to 18 months. In the treatment of printing and dyeing wastewater, composite coated electrodes achieve a decolorization rate of 98.5% for methylene blue, a TOC removal rate of over 65%, and the activity attenuation is less than 5% after 1200 hours of continuous operation. To meet the needs of special scenarios, porous coated titanium electrodes doped with ruthenium and iridium achieve a turbidity removal rate of over 99% in seawater desalination pretreatment, with a corrosion rate lower than 0.1 mm/a.

Fundamental theory of electrochemistry

Faraday’s law, as a fundamental theory in electrochemical research, elaborates on the quantitative relationship between substance changes and electric charge transfer during electrolysis. The law states that there is a strict proportional relationship between the amount of mass change of substances occurring on the electrode surface and the total electric charge passing through the electrode, with the proportional coefficient depending on the molar mass of the substances involved in the reaction and the number of charge transfers. In the coated titanium electrode system, this theory provides a key basis for evaluating the actual catalytic efficiency of the electrode. Especially in the electrolysis industry, by monitoring the current efficiency and the production amount of electrolysis products, the electrochemical activity and stability of the coating material can be effectively verified.

Electrode reaction kinetics theory provides a dynamic analytical framework for interpreting the performance of coated titanium electrodes. This theory elucidates the correlation mechanism between catalytic activity and the microstructure of electrode materials by investigating the quantitative relationship between electrode reaction rates and external conditions such as potential, temperature, and ion concentration. In the study of coated titanium electrodes, the chlorine evolution potential and oxygen evolution potential serve as critical parameters characterizing their catalytic performance. When the electrode surface potential reaches the critical value for chlorine or oxygen evolution, water molecules undergo decomposition reactions on the coating surface. The ease or difficulty of this process directly determines the electrode’s stability under specific electrolytic conditions.

Selection of Coated Titanium Electrodes Materials

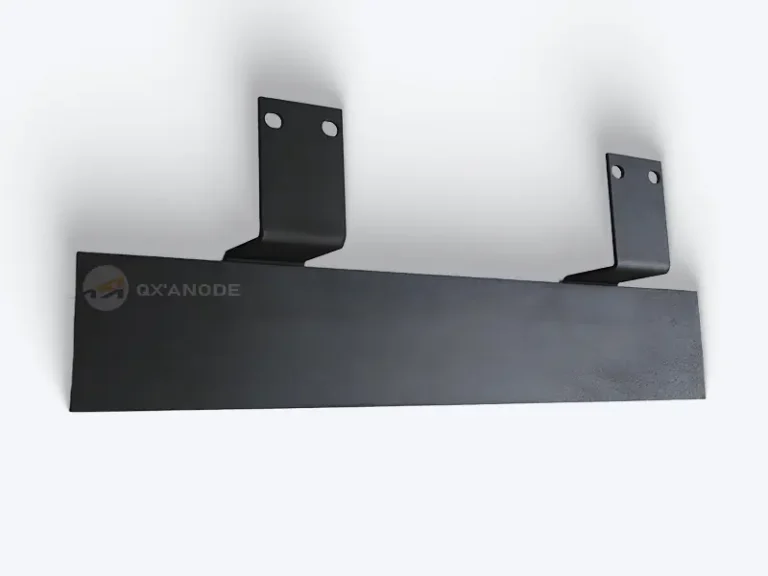

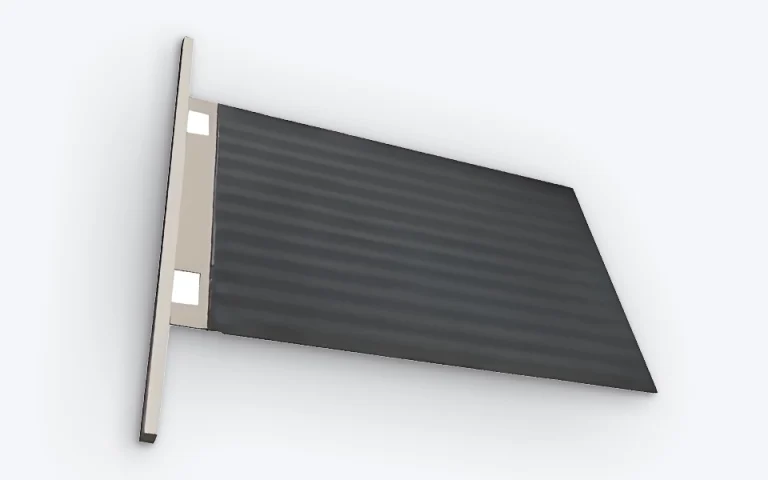

Titanium-based materials have become ideal substrate materials for electrode manufacturing due to their excellent corrosion resistance, biocompatibility, and lightweight properties. The development and processing technologies of modern titanium alloys provide an important foundation for the structural design of coated titanium electrodes. When selecting coating materials, noble metal oxides have attracted much attention because of their high catalytic activity. Among them, ruthenium, iridium, and platinum oxides exhibit significant advantages in electrochemical reactions due to their unique electronic structures and chemical stability.

Ruthenium oxide (RuO₂) has been extensively studied due to its high catalytic activity for the oxygen evolution reaction (OER) under acidic and neutral conditions, and the efficiency of electron transfer on its surface can be further optimized by adjusting the lattice parameters. Iridium oxide (IrO₂) exhibits better durability in alkaline electrolytes, especially maintaining structural stability at high temperatures and high current densities. Platinum-based coatings (Pt or its alloys) are often used in the core regions of hydrogen evolution reactions because of their low overpotential characteristics for the hydrogen evolution reaction (HER), but their high cost limits large-scale applications.

Theory of Coating Preparation Process

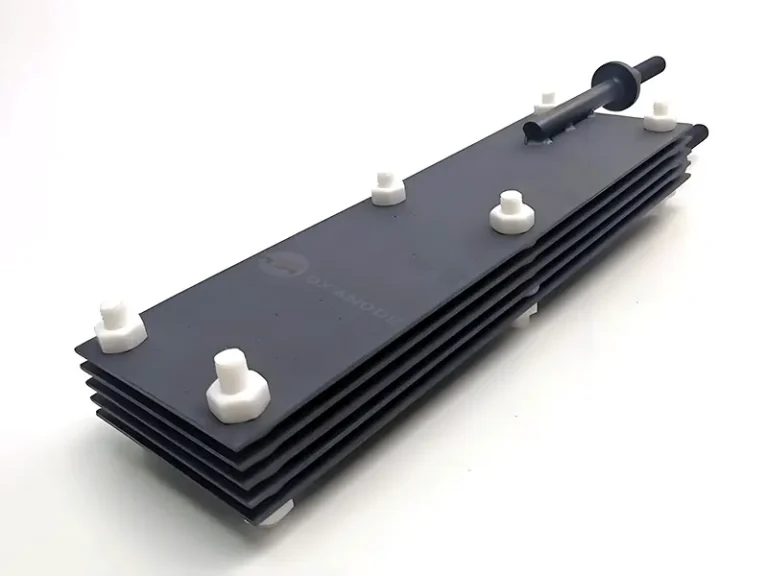

The theory of coating preparation technology is the core foundation for optimizing the performance of coated titanium electrodes. It enhances the functional characteristics of electrodes through specific material synthesis and structural design. The preparation of titanium-based coated electrodes needs to consider the material’s phase composition, microstructure, and electrochemical performance requirements. Common preparation methods include thermal decomposition and electrodeposition. The thermal decomposition method uses metal organic precursors or composite solutions as raw materials, and forms an active coating through decomposition reactions under high-temperature conditions. By controlling parameters such as precursor ratio, heat treatment temperature, and time, this method can achieve uniform distribution of nanoscale active components.

Recent studies have proposed a method for preparing titanium-based active coatings, which involves the steps of impregnation with a precursor solution and heat treatment to form a strong bond between the active components and the titanium substrate, significantly enhancing the corrosion resistance and conductivity of the coating.

The regulation of the microstructure of the coating has an important impact on the performance of the electrode. For example, by controlling the annealing temperature in the thermal decomposition method, oxide coatings with different crystal phases can be formed on the titanium substrate, which in turn affects their electrocatalytic activity.

Electrochemical properties of coated titanium electrodes

In a 1mol/L NaCl solution, the coated electrode with RuO₂ as the main active component exhibits a low chlorine evolution potential (approximately 1.14 V vs. SCE), indicating that the coating effectively inhibits the oxygen ion discharge side reaction. When the electrolyte is switched to a 3mol/L NaOH solution, the composite coated electrode doped with IrO₂ shows excellent oxygen evolution performance. Its oxygen evolution overpotential is 380mV at a current density of 10mA/cm², which is 12% lower than that of traditional electrodes, and the Tafel slope is 68mV/dec, confirming the significant optimization effect of the coating on the kinetics of the oxygen evolution reaction. Electrochemical impedance spectroscopy (EIS) analysis shows that the interfacial charge transfer resistance (Rct) of the coated electrode with a porous structure is only 14Ω·cm², which is 40% lower than that of the dense coating. This is closely related to the increase in electrode surface area and the uniformity of active site distribution.

In practical application simulations, the current efficiency of coated titanium electrodes in electrolytic cells for seawater desalination pretreatment reaches 89%, and they retain more than 90% of their activity after 1000 hours of continuous operation. These results confirm that by optimizing the coating composition and microstructure, the chlorine evolution/oxygen evolution potential difference of titanium electrodes can be effectively regulated, while improving reaction kinetics and long-term stability, providing key data support for the engineering application of high-performance electrodes.

Corrosion resistance of coated titanium electrodes

The corrosion resistance of different coated titanium electrodes in strong acid (1 mol/L H₂SO₄) and strong alkali (1 mol/L NaOH) environments was systematically evaluated through electrochemical impedance spectroscopy (EIS), potentiodynamic polarization curves, and potentiostatic anodic polarization tests. The experimental results show that the type of coating has a significant impact on the corrosion resistance of the electrodes. In the strong acidic medium, the corrosion current density (Icorr) of the iridium (Ir)-based coated electrode is 0.021 μA/cm², which is two orders of magnitude lower than that of the uncoated titanium substrate (Icorr = 1.85 μA/cm²), and its open-circuit potential (Eoc) reaches +0.68 V (vs. SCE), showing excellent passivation characteristics. Electrochemical impedance spectroscopy analysis reveals that the polarization resistance (Rp) of the Ir-coated electrode in acidic solution is as high as 1.2×10⁵ Ω·cm², and the diameter of the semicircle in the high-frequency region of the Nyquist plot is significantly larger than that of other coating systems, indicating that the oxide film formed on its surface has higher compactness and stability. In contrast, the Rp value of the ruthenium (Ru)-based coating under the same conditions is 6.7×10⁴ Ω·cm², and the corrosion rate is approximately 38% higher than that of the Ir coating, which may be related to the higher lattice defect density of the Ru oxide film.

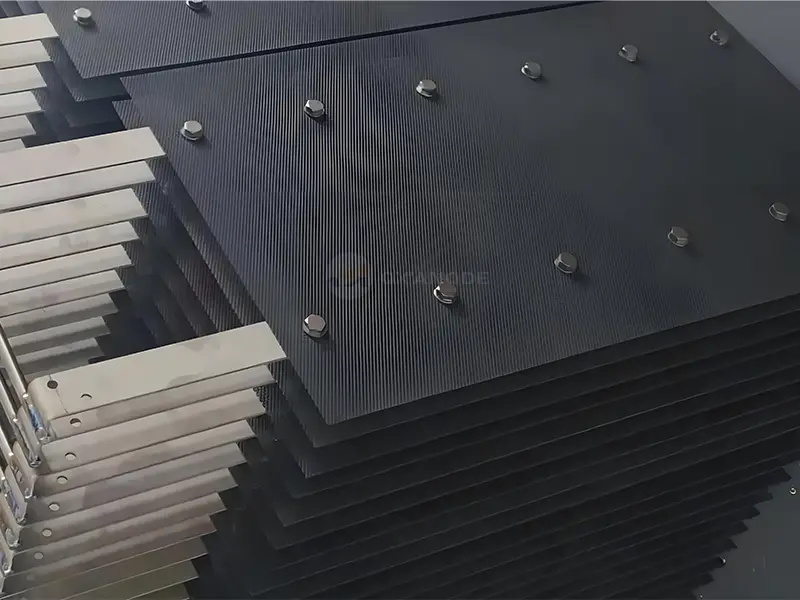

Applications of Coated Titanium Electrodes

In the chlor-alkali industry, coated titanium electrodes exhibit significant performance advantages as anode materials. Traditional graphite anodes are prone to oxidative corrosion in a strongly alkaline electrolytic environment, leading to a decrease in current efficiency and frequent replacements. In contrast, titanium anodes with a ruthenium-iridium oxide coating effectively reduce the chlorine evolution overpotential by optimizing the coating thickness and composition.

In the field of water treatment, coated titanium electrodes exhibit high efficiency in pollutant degradation in electrocatalytic oxidation technology. For the treatment of printing and dyeing wastewater, their surface charge density is 42% higher than that of traditional metal oxide coatings. In electrolysis experiments with simulated dye wastewater (methylene blue concentration of 20 mg/L), the decolorization rate can reach 98.5% within 60 minutes, and the TOC removal rate exceeds 65%. Actual engineering application cases show that after a wastewater treatment station in a chemical industrial park adopted this electrode system, the CODcr removal efficiency increased from 72% to 89%, and the activity attenuation of the electrode was less than 5% after 1200 hours of continuous operation, demonstrating excellent stability.

Coated titanium electrodes effectively balance conductivity, catalytic activity, and corrosion resistance through precise regulation of coating components and microstructure. Their practical application effects in industrial scenarios are significantly better than traditional electrode materials. The continuous optimization of coating technology will further promote its large-scale application in the fields of new energy, environmental protection, and chemical industry, providing key technical support for energy conservation and emission reduction in related industries.